Pyrolysis garbage technology performed by means of double-cylinder rotary kiln

A rotary kiln, pyrolysis technology, applied in the field of environmental engineering, can solve the problems of ingress, gas pollution, environmental impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

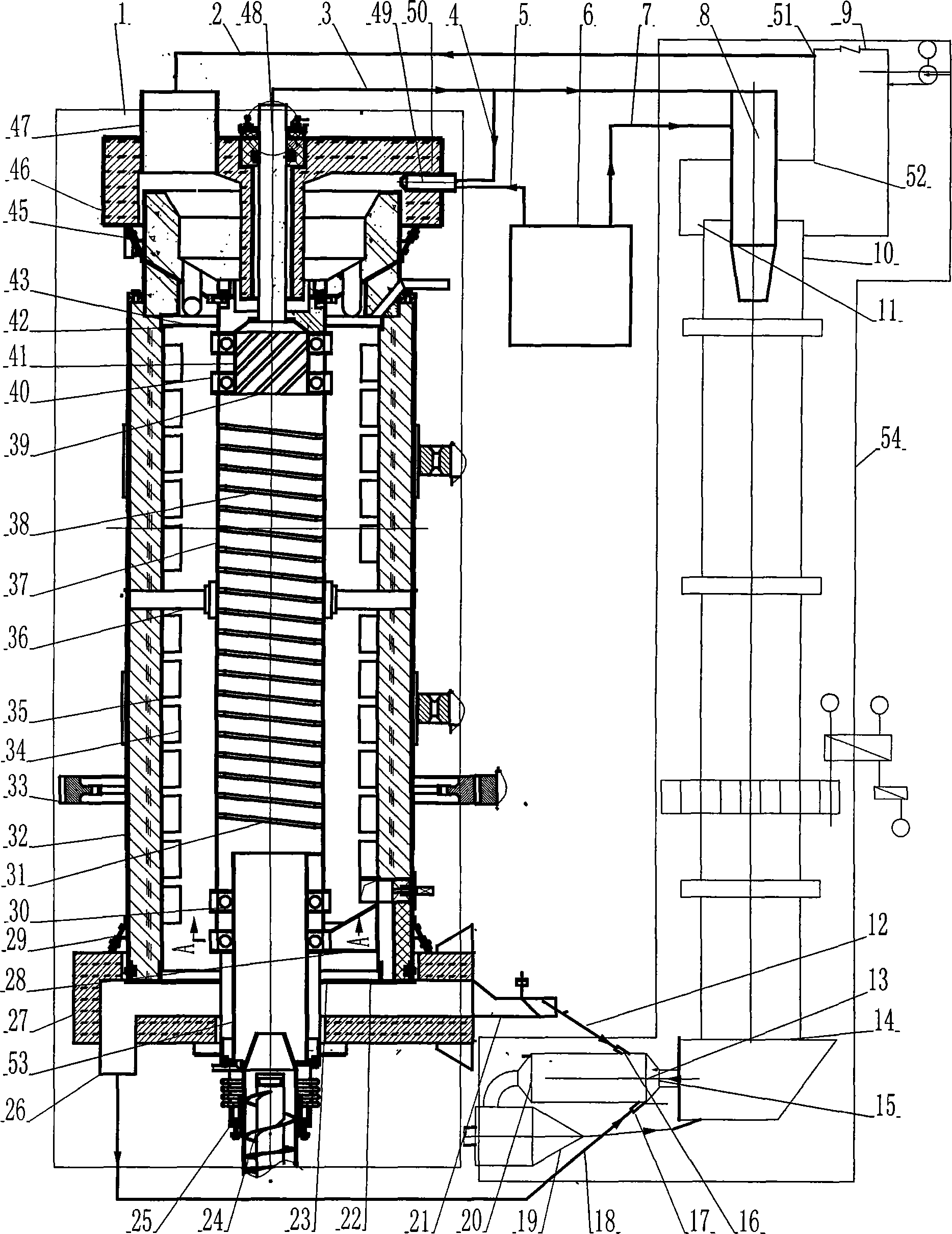

[0029] Double cylinder rotary kiln pyrolysis waste process, the process includes:

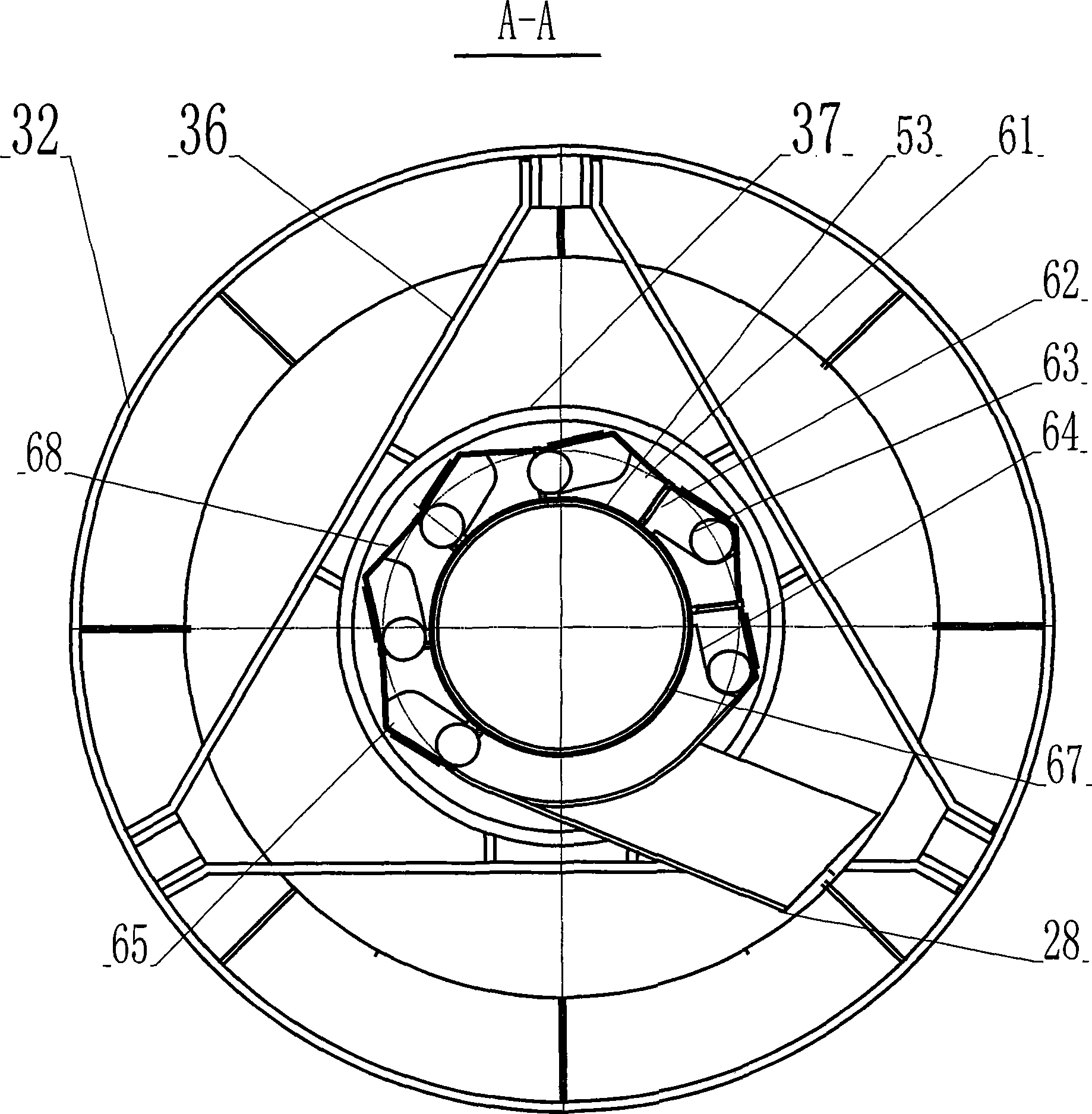

[0030] Double-barrel rotary pyrolysis kiln 1, which includes: pyrolysis channel 38, ash slag return heat channel 35, feeding device 24, kiln head cover 27, which includes exhaust gas interface 26, garbage slag outlet 21, kiln tail cover 46, It includes a composite gas outlet pipe 48, a hot air inlet port 47, a supplementary heat combustion channel 50, and a supplementary heat burner 49, which are installed in the supplementary heat combustion channel;

[0031] Cement production line 54, including: cement rotary kiln 10, clinker cooler 9, precalciner 13, preheater 19; the cement rotary kiln includes: kiln head 11, kiln tail 14, multi-channel burner 8 , which is installed at the head of the kiln; the clinker cooler contains: a hot air outlet 51, a hot clinker inlet 52, which is connected to the head of the cement rotary kiln; the precalciner contains an upper Exhaust port 20, a lower air inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com