Coal dry distillation method and device for realizing same

A technology of coal and dry distillation, applied in the field of coal chemical industry, can solve the problems of large-scale production equipment, difficult transportation, uneconomical operation of equipment, etc., and achieve the effect of improving the utilization rate of calorific value, improving the heat efficiency of dry distillation, and improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

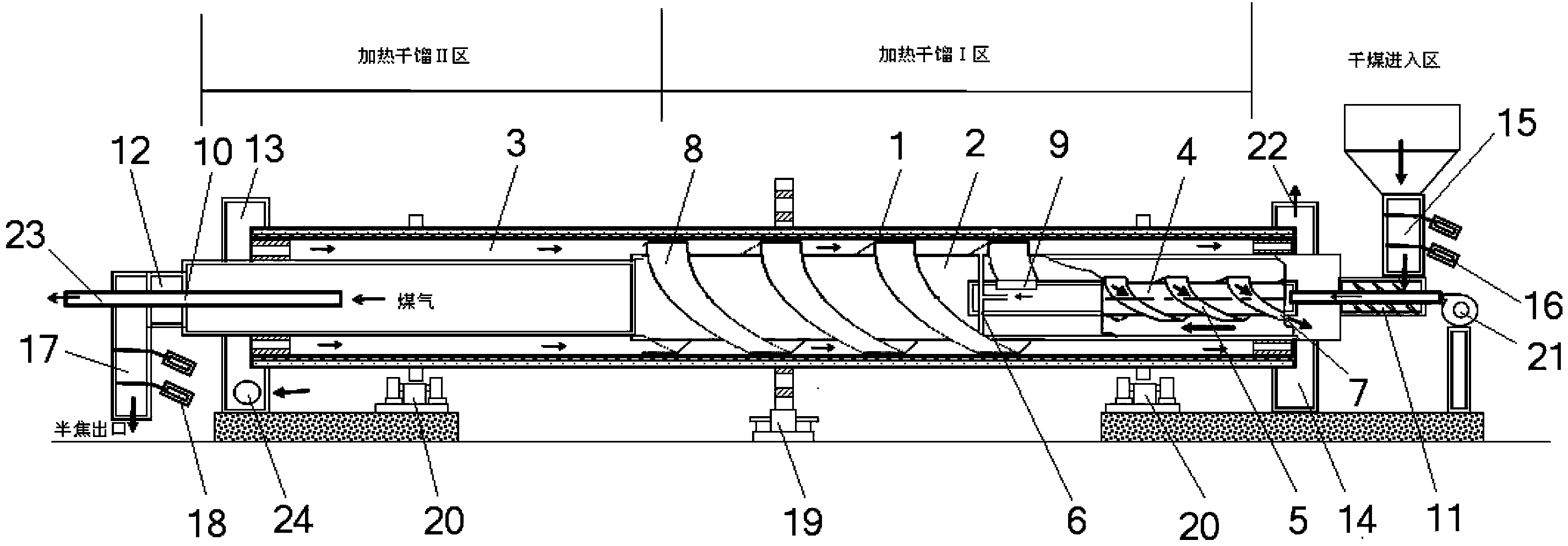

[0033] As shown in Figure 2, the device provided by this embodiment includes an outer cylinder 1, an inner cylinder 2 fixedly installed in the outer cylinder 1 through a support ring, and an axial flue 3 formed between the inner and outer cylinders. The outer cylinder 1 passes through two channels Supported by the supporting wheel and the rolling ring 20, the middle large gear and the transmission device 19 provide power for the overall rotation of the inner and outer cylinders.

[0034] One end of the inner cylinder 2 is the feed end, and the other end is the discharge end; the feed end of the inner cylinder 2 is equipped with a feed screw 11 through a dynamic and static plate, and then the dynamic sealing connection between the inner cylinder 2 and the feed screw 11 is realized. , that is to say that the inner cylinder 2 and the feeding screw 11 do not rotate together, the inlet of the feeding screw 11 is equipped with a vertical feeding channel 15 through a dynamic and stati...

Embodiment 2

[0044] refer to figure 2 , the device of this embodiment differs from that of Embodiment 1 in that: the feed inlet 9 is far away from the discharge end, and a feed screw 8 is fixedly installed on the entire outer wall of the inner cylinder 2 located in the heating and carbonization zone I; The outlet is far away from the feed end, and the whole part of the outer wall of the combustion tube 4 is fixed with a hot semi-coke return screw 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com