Coal gas anhydrous dust collecting equipment of revolving furnace and technique thereof

A converter gas and process method technology, applied in the direction of gas dust removal, chemical industry, climate sustainability, etc., can solve the problems of increased power of the main induced draft fan, loss of water vapor content, increase, etc., to improve the utilization rate of calorific value , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

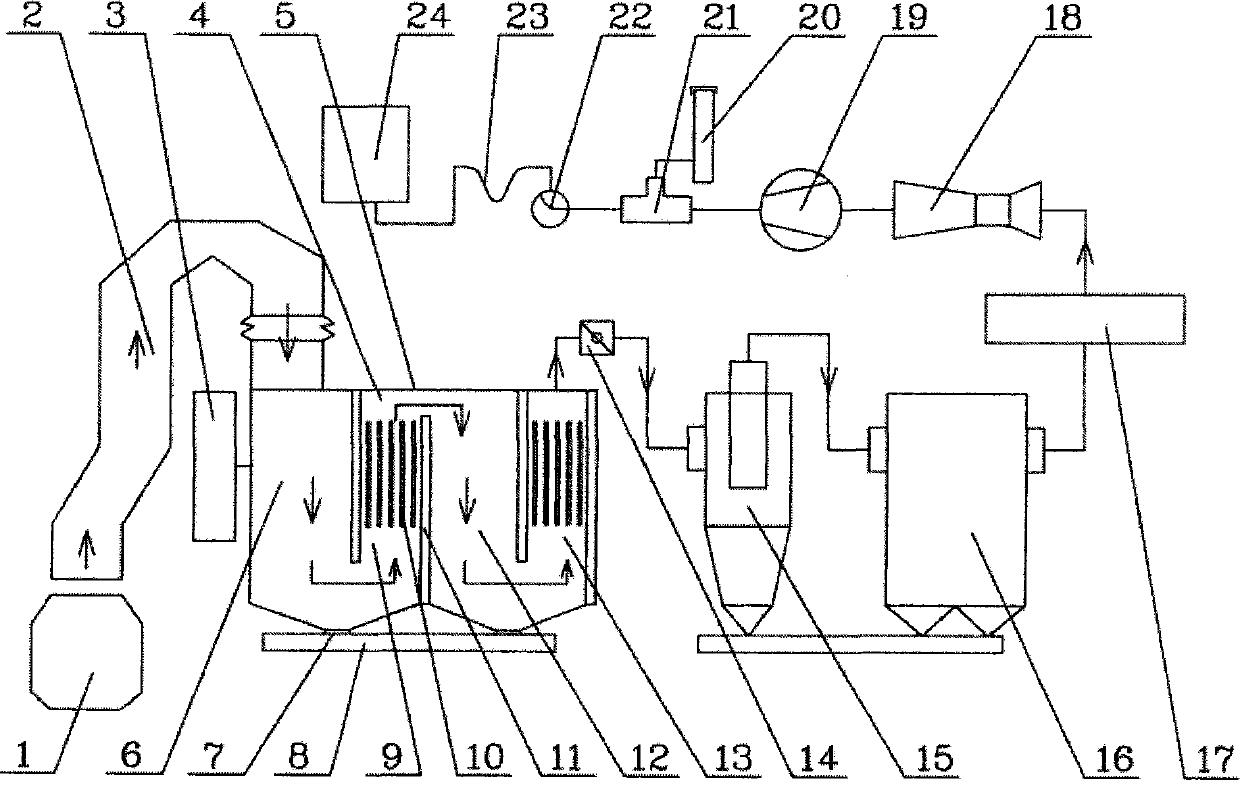

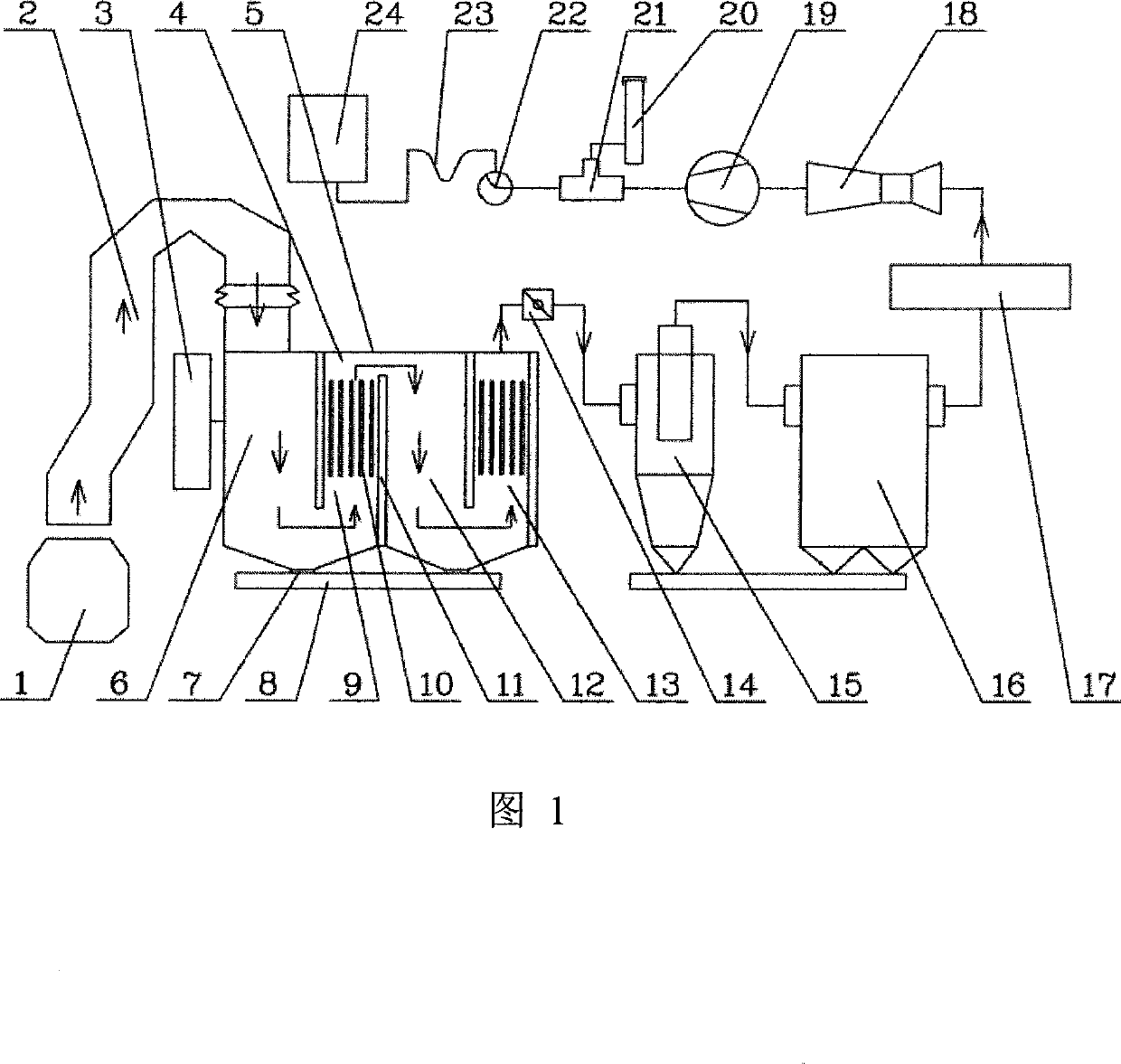

[0010] figure 1 It is a schematic diagram of the mechanism in the embodiment of a converter gas anhydrous dedusting equipment and process method of the present invention, as figure 1 As shown, the method of this embodiment of the invention is as follows: the high-temperature gas generated by the converter 1 passes through the radiant waste heat boiler 2 and transfers part of the heat to the indirect cooling water to generate steam for recovery. After the heat exchange, the temperature of the gas is reduced to 900-1000°C Then enter the convection waste heat boiler 4. In the settling chambers 6 and 12 of the convection waste heat boiler 4, the gas undergoes two gravity settlements, and passes through two convection heat exchange components in the convection heat exchange chambers 9 and 13 to generate steam to recover waste heat. After reducing the temperature of the gas to 250-300°C, the gas enters the regulating valve 14 used to adjust the differential pressure at the furnace m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com