Biomass particle hot-blast furnace

A biomass pellet and hot blast stove technology, which is used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of incomplete combustion of fuel, large changes in fuel size, and short service life, so as to achieve full combustion, The effect of improving heat recovery and saving recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

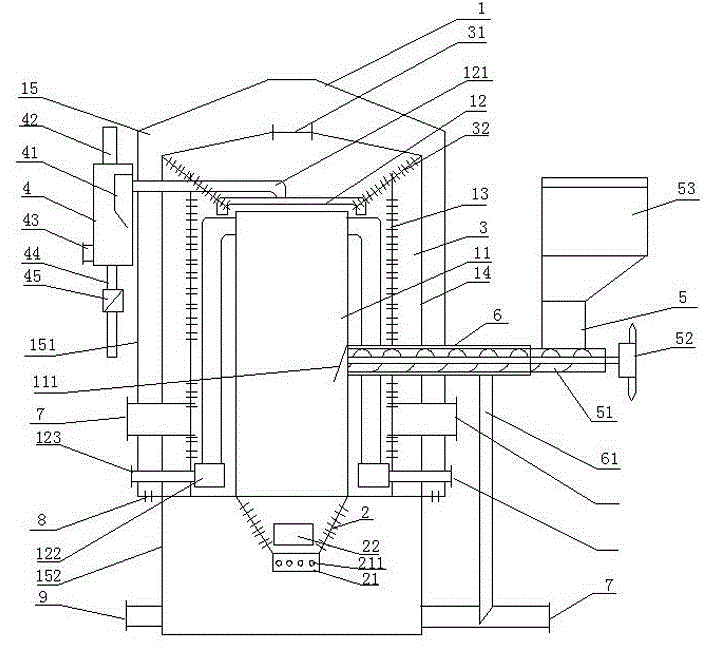

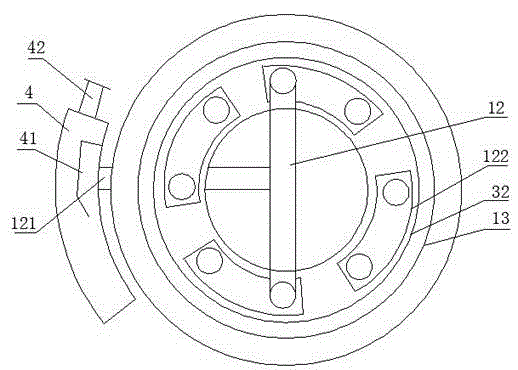

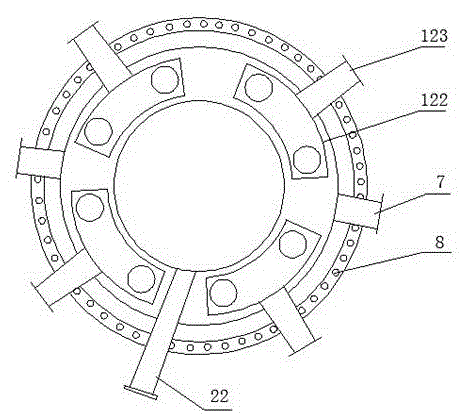

[0028] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] like Figure 1~Figure 3 Shown: a biomass particle hot air stove, including a furnace body 1, the furnace body 1 is provided with a fire chamber 11, a flue gas connecting pipe 12, a sieve plate type heat exchange plate 13, a heat conducting plate 14 and a furnace shell 15 in sequence from the inside to the outside , The lower part of the furnace 11 is provided with a furnace 2. The fire chamber 11 is made of a heat-conducting material, which can quickly transfer the heat of the furnace 2 to the fire chamber 11, so that the fire chamber 11 is evenly heated and improves thermal efficiency. Furnace shell 15 is made of high temperature resistant steel plate, and has good heat preservation and cooling effect. The upper part of the furnace cavity 3 surrounded by the heat conducting plate 14 is provided with a heat ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com