System and method for intelligently controlling temperature of internal arc angle part in straightening region of wide and thick plate blank

A technology of intelligent control and straightening zone, which is applied to accurately control the temperature of the inner arc corner of the wide and thick slab continuous casting slab entering the straightening zone, and intelligently and accurately control the inner arc angle of the slab in the secondary cooling and straightening zone of the wide and thick slab continuous casting machine In the field of internal temperature, it can solve the problems of frequent occurrence of micro-transverse cracks, intensified segregation, high shell temperature, etc., and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

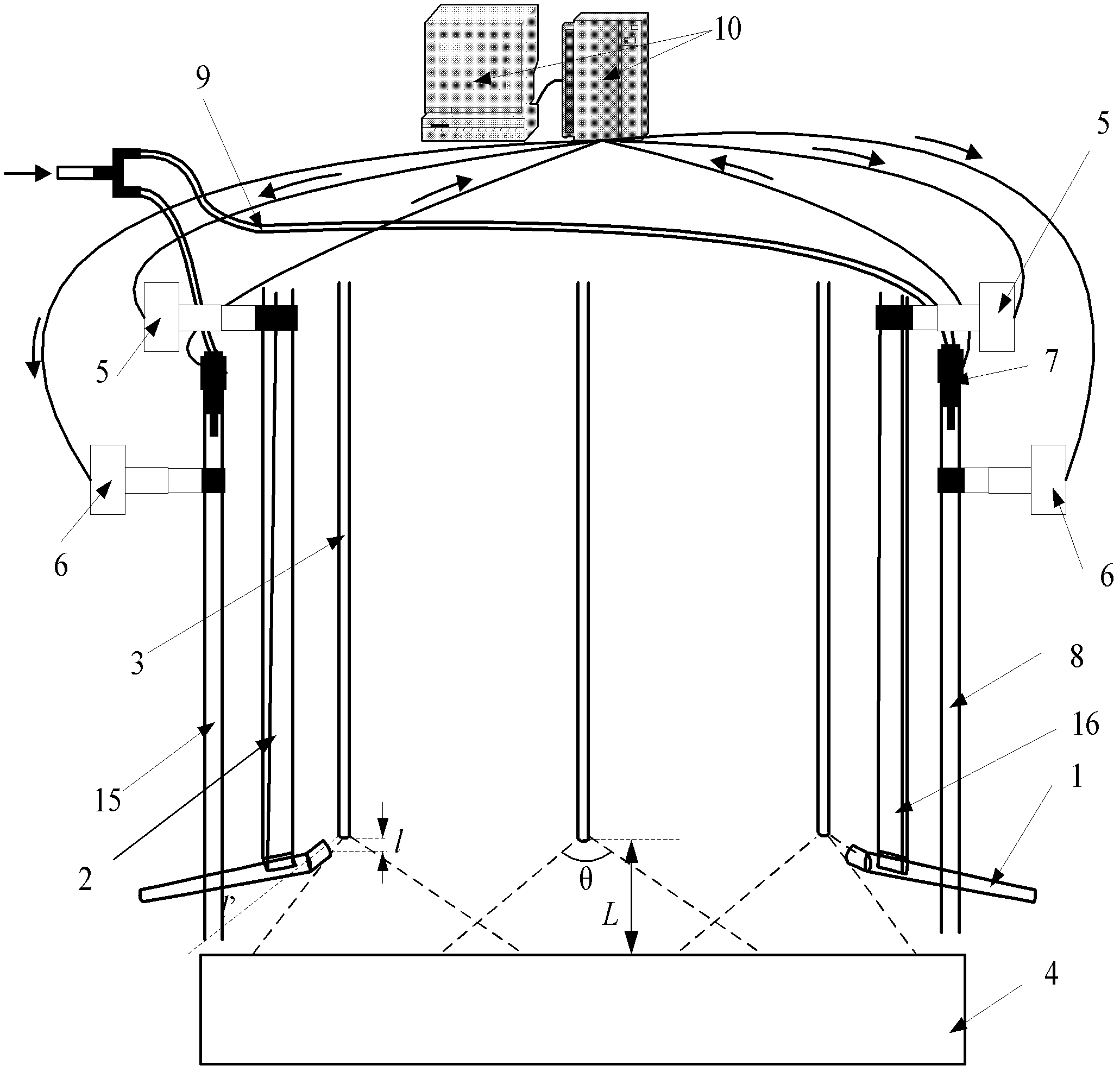

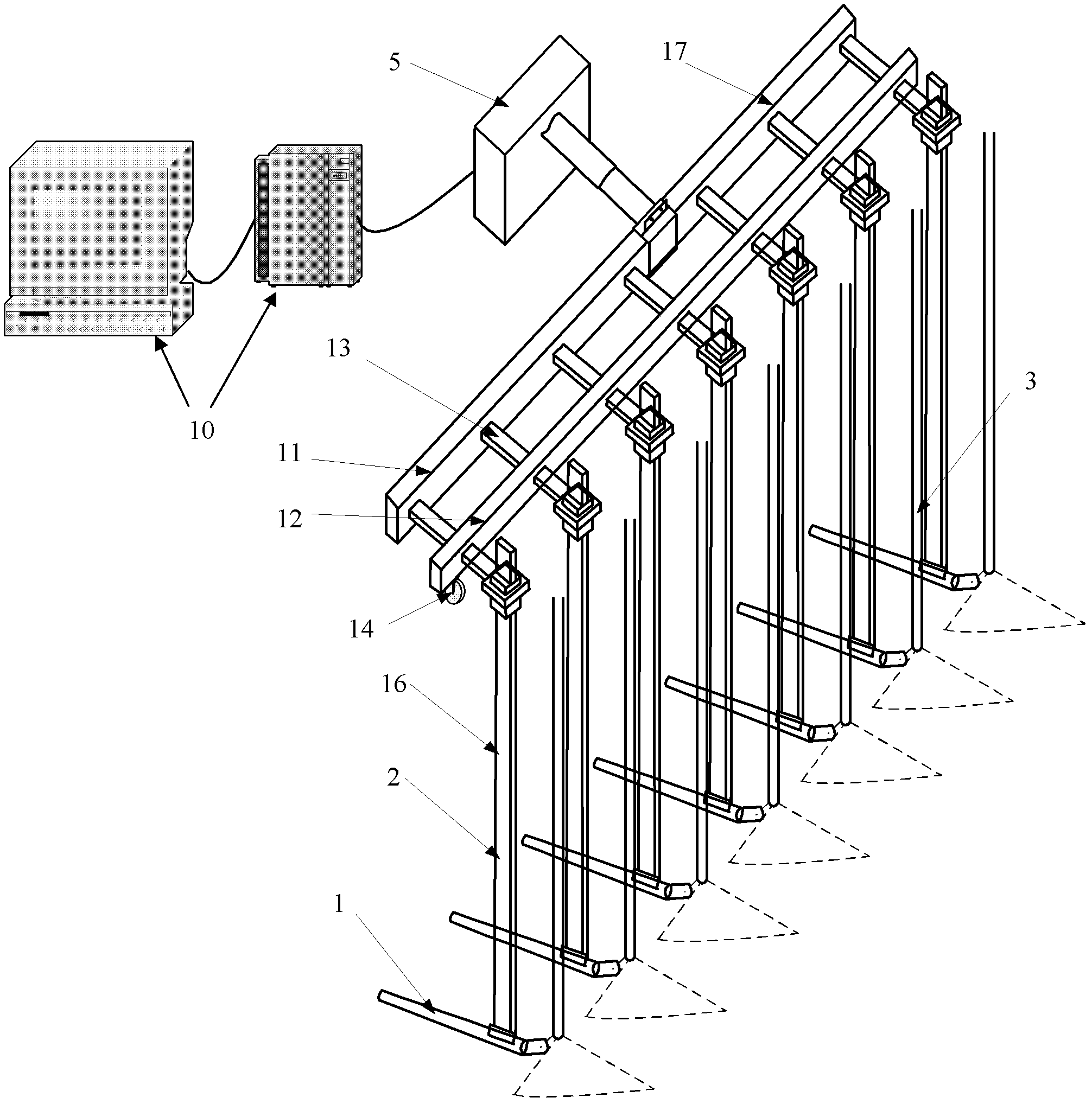

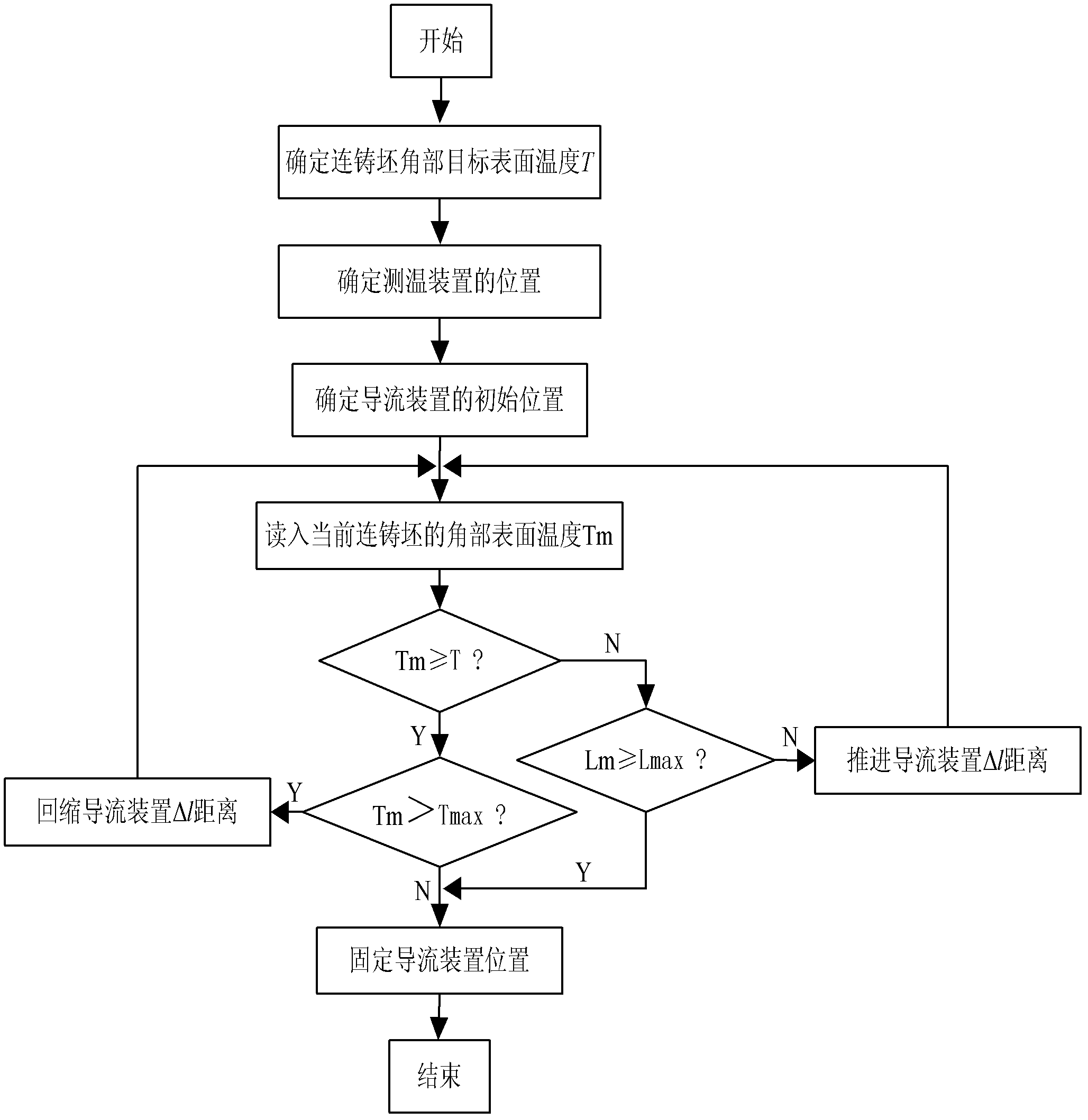

[0037] Such as figure 1 , figure 2 As shown, a system for intelligently controlling the temperature of the inner arc corner in the straightening area of wide and thick slabs includes a temperature measuring device 15, a flow guide device 16 and a control system 10. The temperature measuring device 15 is made of a stainless steel temperature measuring tube 8 Composed of a non-contact infrared temperature measuring probe 7, the infrared temperature measuring probe 7 is arranged on the upper end of the temperature measuring tube 8, and the upper end of the temperature measuring tube 8 is connected with the compressed air pipeline 9; the flow guiding device 16 is composed of The horizontal support frame 17, the support frame connecting rod 2 and the cooling water collection guide pipe 1 are composed, the top of the support frame connecting rod 2 is connected with the horizontal support frame 17, the bottom end of the support frame connecting rod 2 is connected with the cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com