Front wall vertical plate assembly welding tool

A welding tooling and assembly technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems affecting the health of workers, high workpiece temperature, and affecting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples.

[0018] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

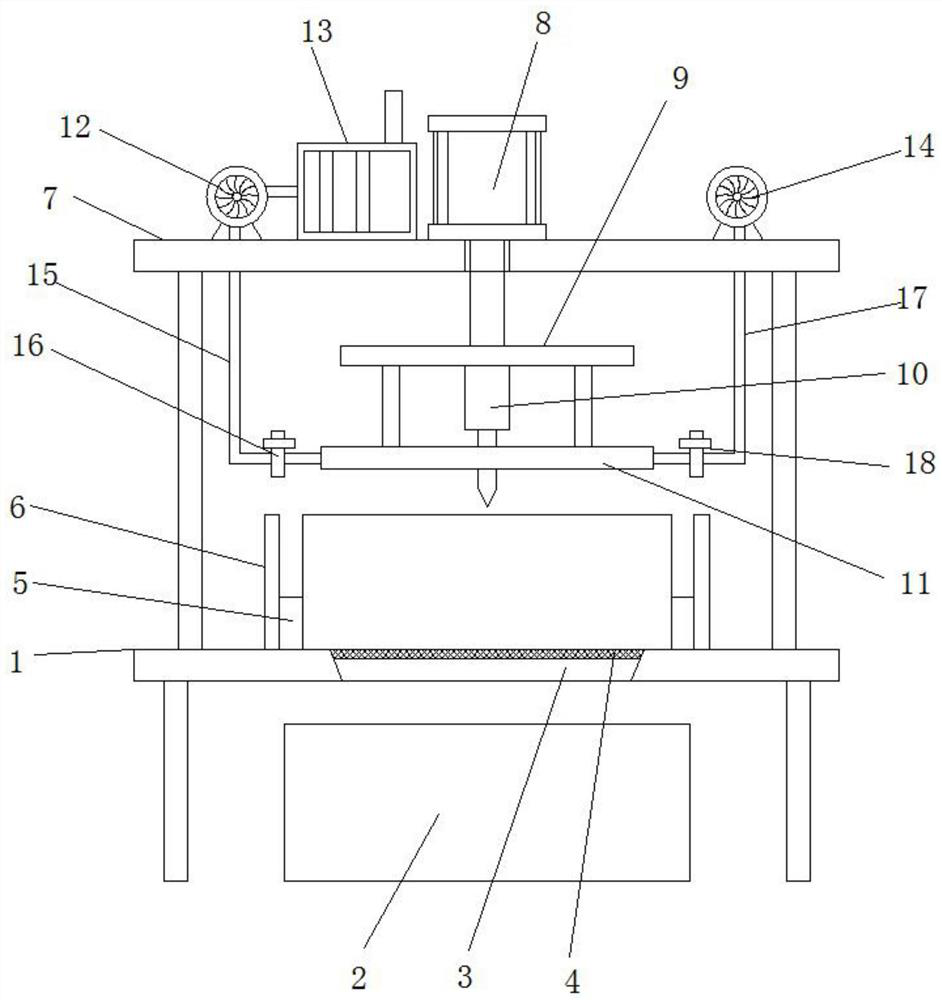

[0019] see Figure 1-4 , the present invention provides a welding tool for the dash riser assembly, including a welding station 1 and a collection box 2, the welding station 1 is provided with a blanking hole 3, the collection box 2 is a cuboid structure with an open top, and the collection The box 2 is located directly below the feeding hole 3 .

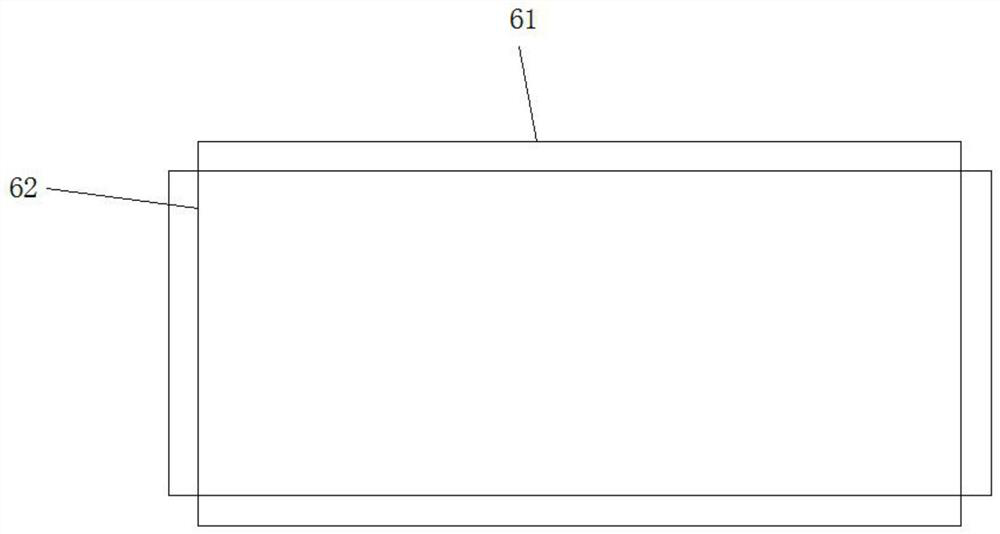

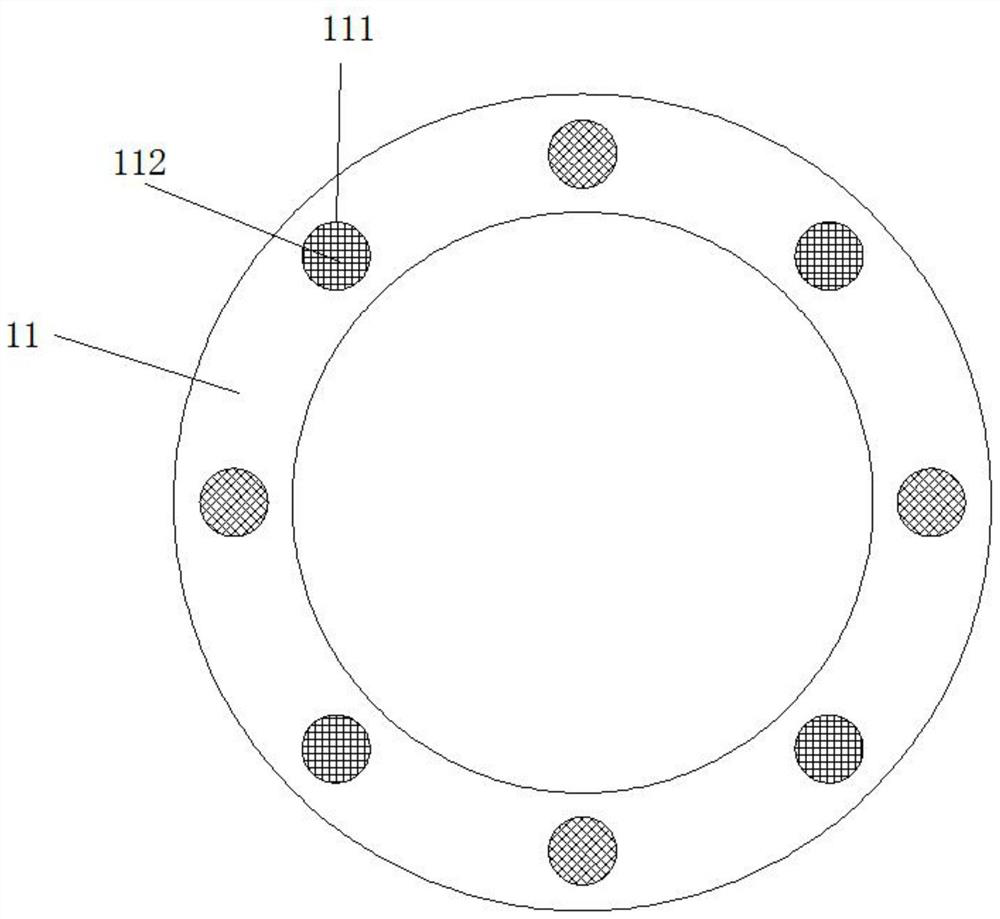

[0020] A grid plate 4 is arranged in the blanking hole 3, a positioning block 5 is arranged symmetrically on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com