Extrusion cooling method of pipe production line

A cooling method and production line technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as low pass rate, fluffing and packing, and affect product performance, so as to avoid many defective products, long service life, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiments, but the present invention is not limited.

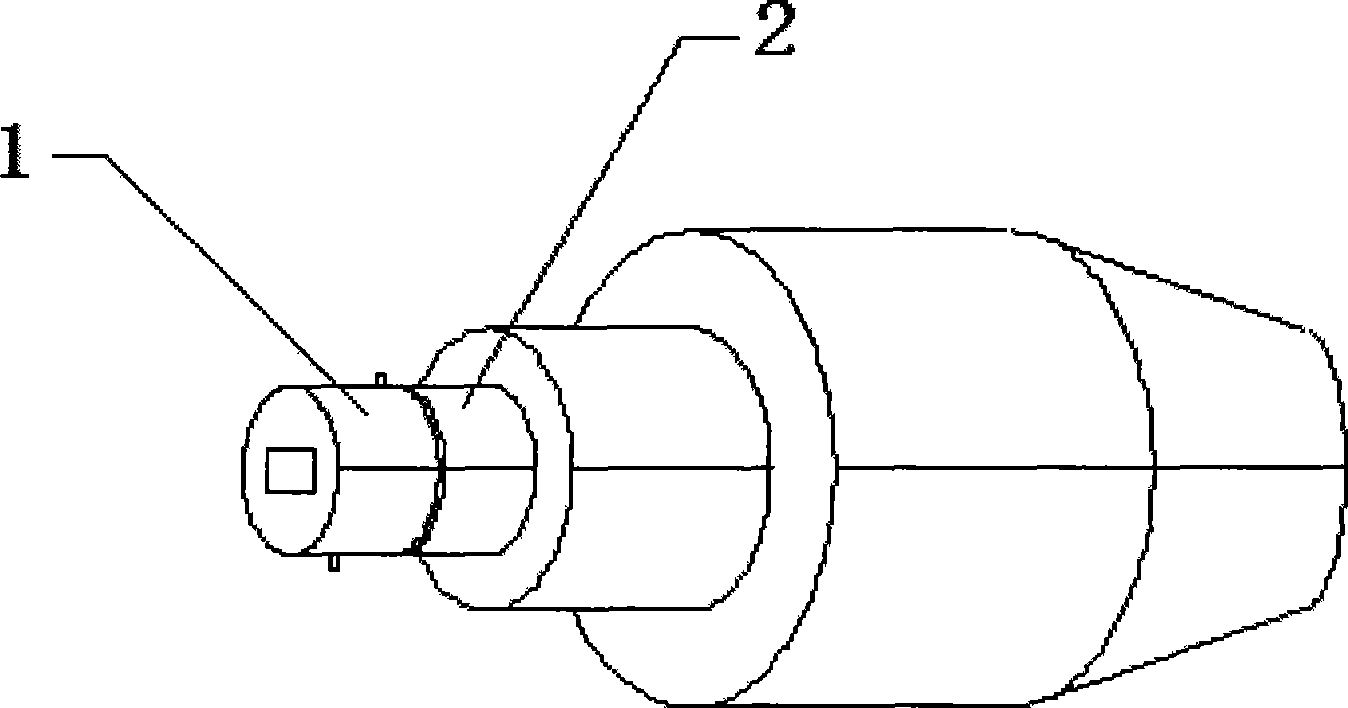

[0025] figure 1 Shown is an extrusion die with a cooling device. The cooling device is a ring structure, so it can be called a cooling ring. The middle channel of the cooling ring 1 communicates with the extrusion die, and the ring wall of the cooling ring 1 is provided with a coolant The channel is used to cool the product extruded from the extrusion die 2 through the coolant in the coolant channel.

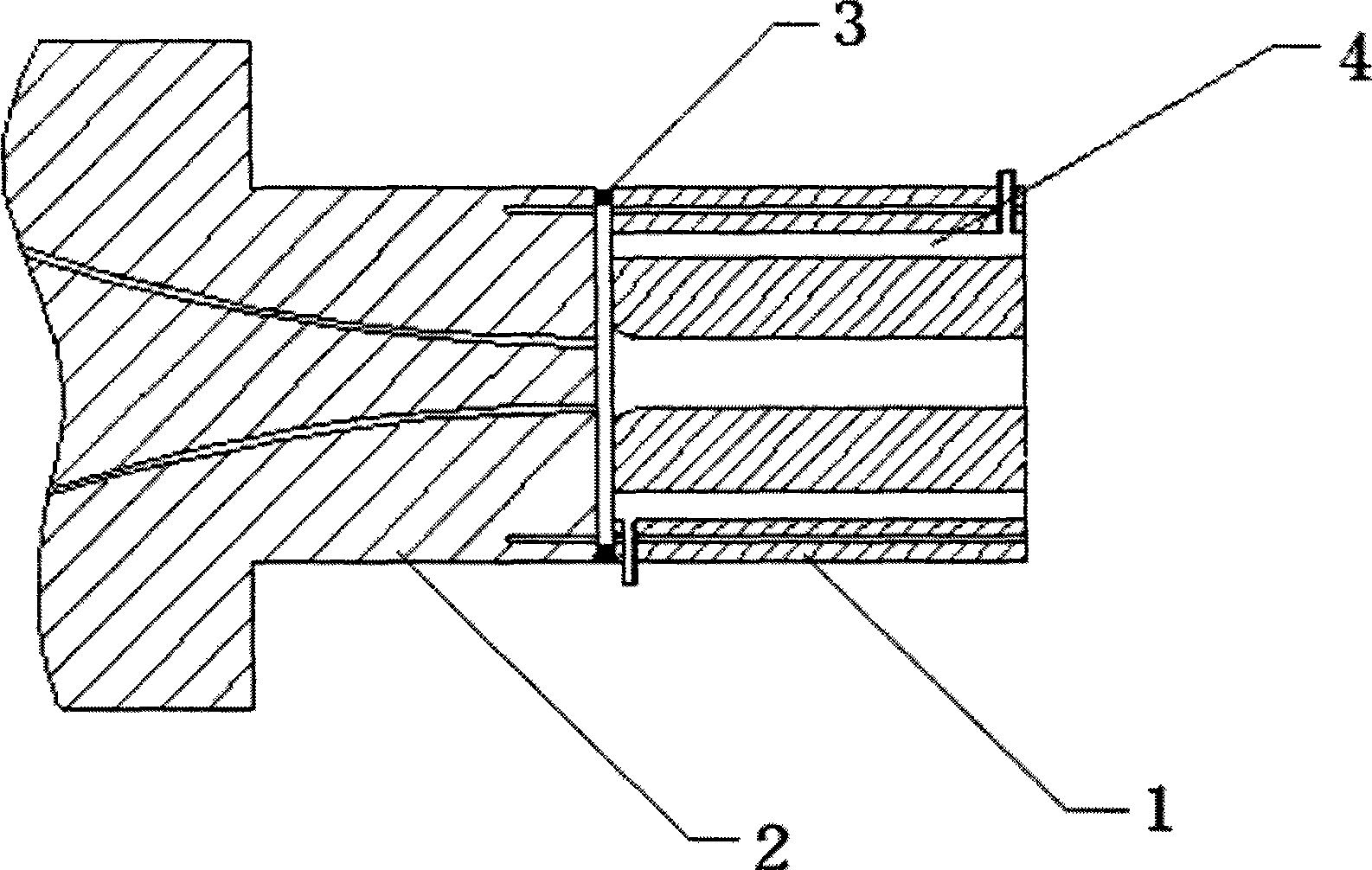

[0026] When the coolant channel is a cavity structure, such as figure 2 As shown, the cooling ring 1 is fixed at the welding point 3 by welding at a distance of about 0.5 mm from the die 2. When the product is extruded into the cooling ring 1 through the die 2, the coolant silicone oil is in the coolant of the cavity structure The channel 4 circulates, so as to cool down the product extruded by the die.

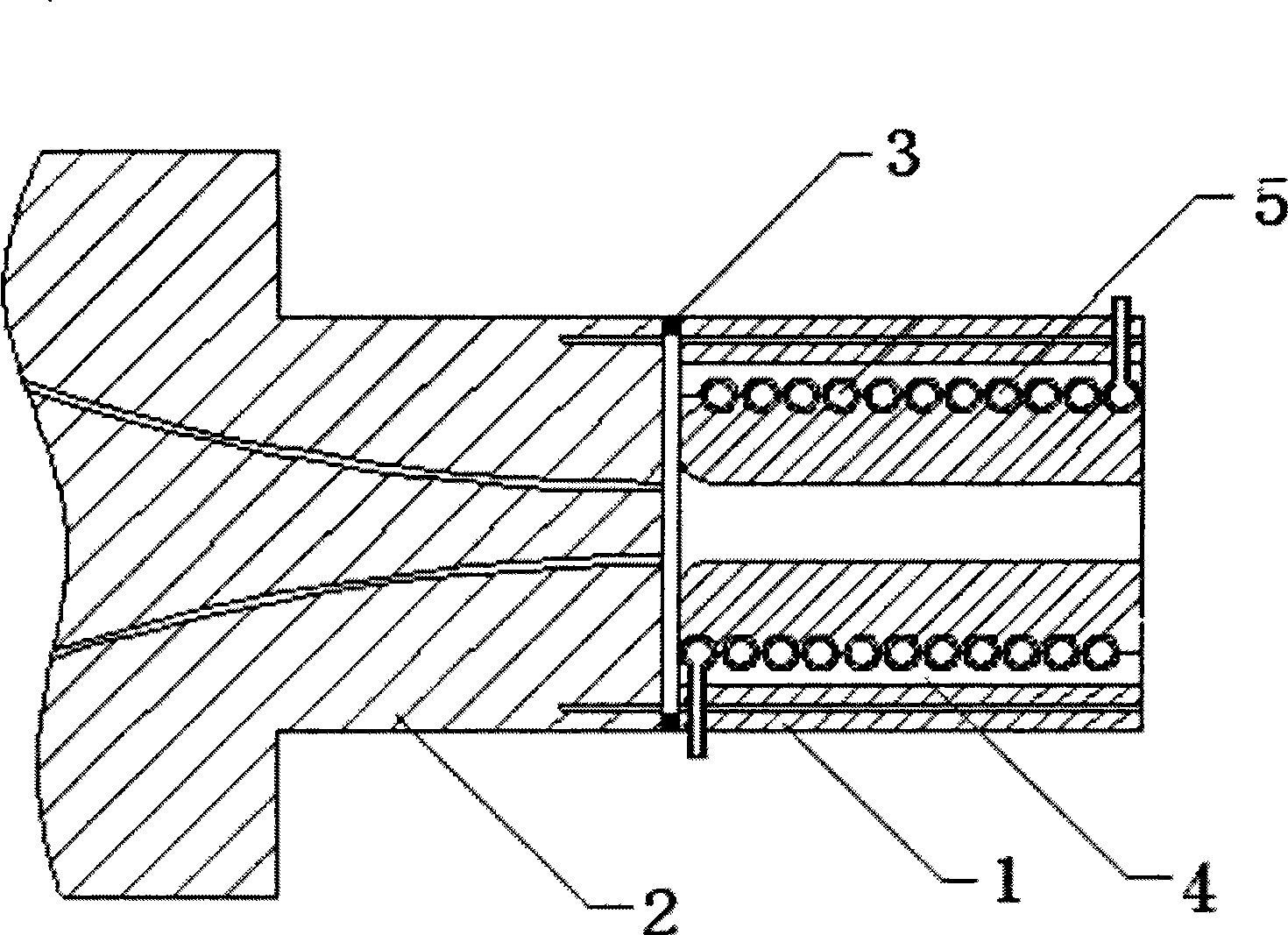

[0027] Such as image 3 As shown, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com