Device for reducing cold air doping rate of hot primary air

A technology of secondary air and cold air, applied in lighting and heating equipment, combustion method, block/powder fuel preparation, etc., can solve problems such as poor effect and deviation of boiler efficiency, so as to reduce coal cost for power generation and improve boiler efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

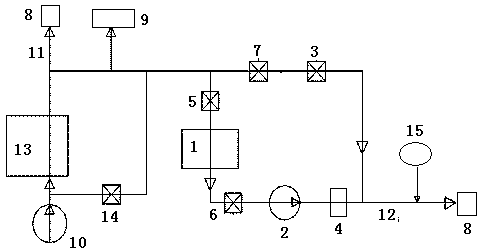

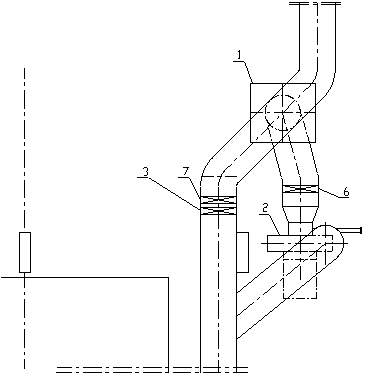

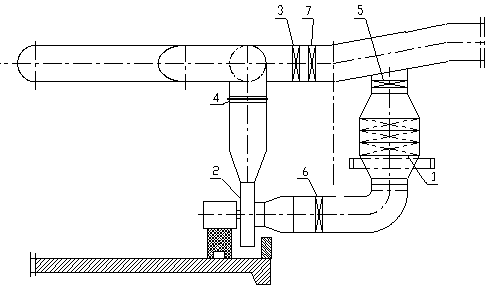

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] The device for reducing the mixing rate of hot primary air and cold air of the present invention comprises a blower 10, an air preheater 13, and a burner 8 connected in sequence along the air inlet direction. The air preheater is connected to the burner through a primary air pipe, and there is a The beginning and end of the bypass air duct are connected to different positions on the primary air duct, and the flow direction of the internal air is consistent with that of the primary air duct. The bypass air duct is sequentially provided with inlet shut-off baffles 5 along the air inlet direction. , hot primary air cooler 1, outlet shut-off baffle 6, booster fan 2 and air duct compensator 4; the part between the beginning and end of the bypass air duct on the primary air duct is arranged in sequence along the air inlet direction Adjust baffle plate 7 and shut off baffle plate one 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com