Electric-bag combined converter gas dry cleaning and recovering system

A converter gas, dry purification technology, applied in the manufacture of converters and other directions, can solve the problems of low dust removal accuracy, reduced dust removal efficiency, explosion of electrostatic precipitators, etc., to reduce the amount of spray cooling water, increase the recovery of waste heat, and reduce cooling. load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

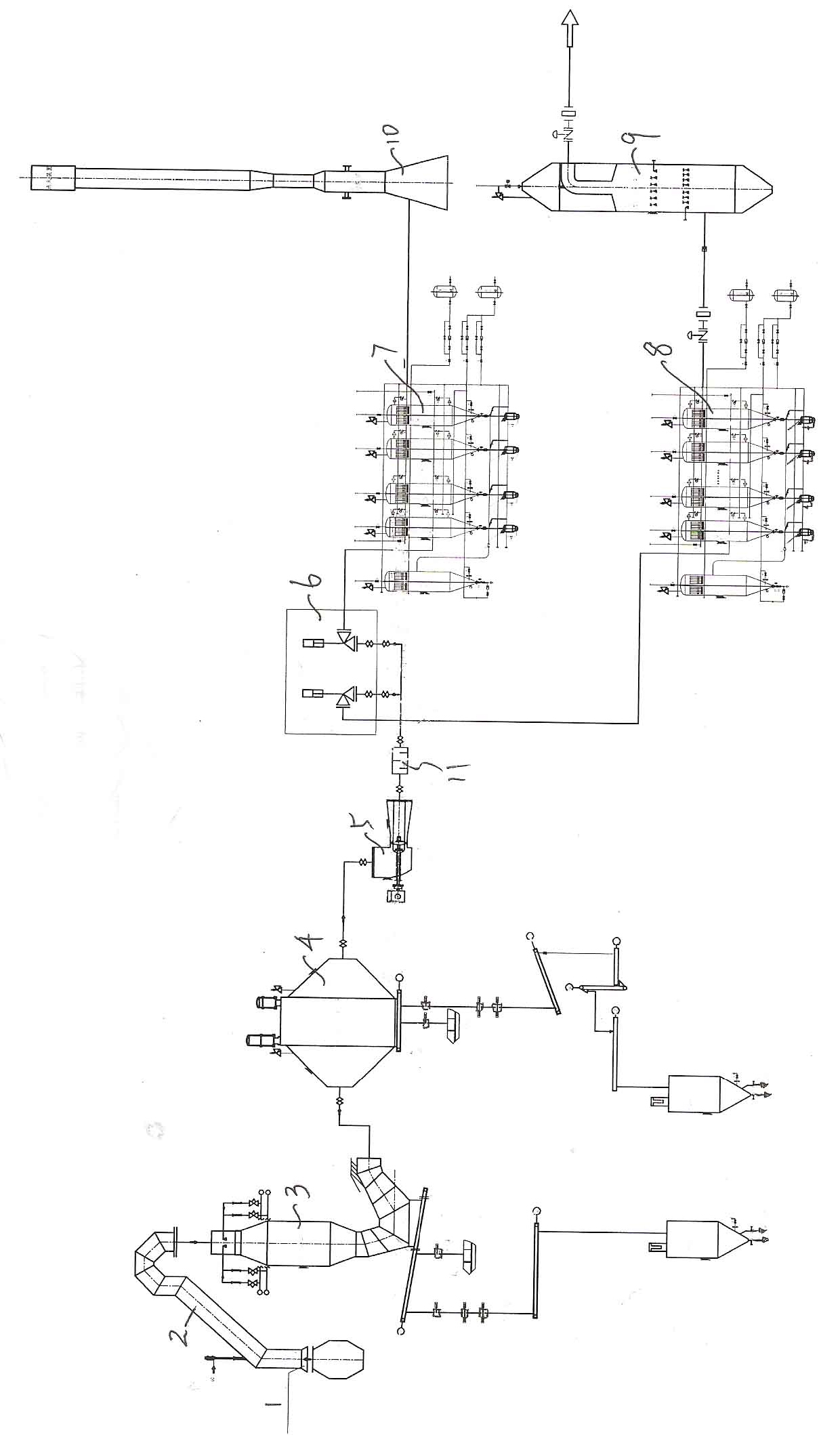

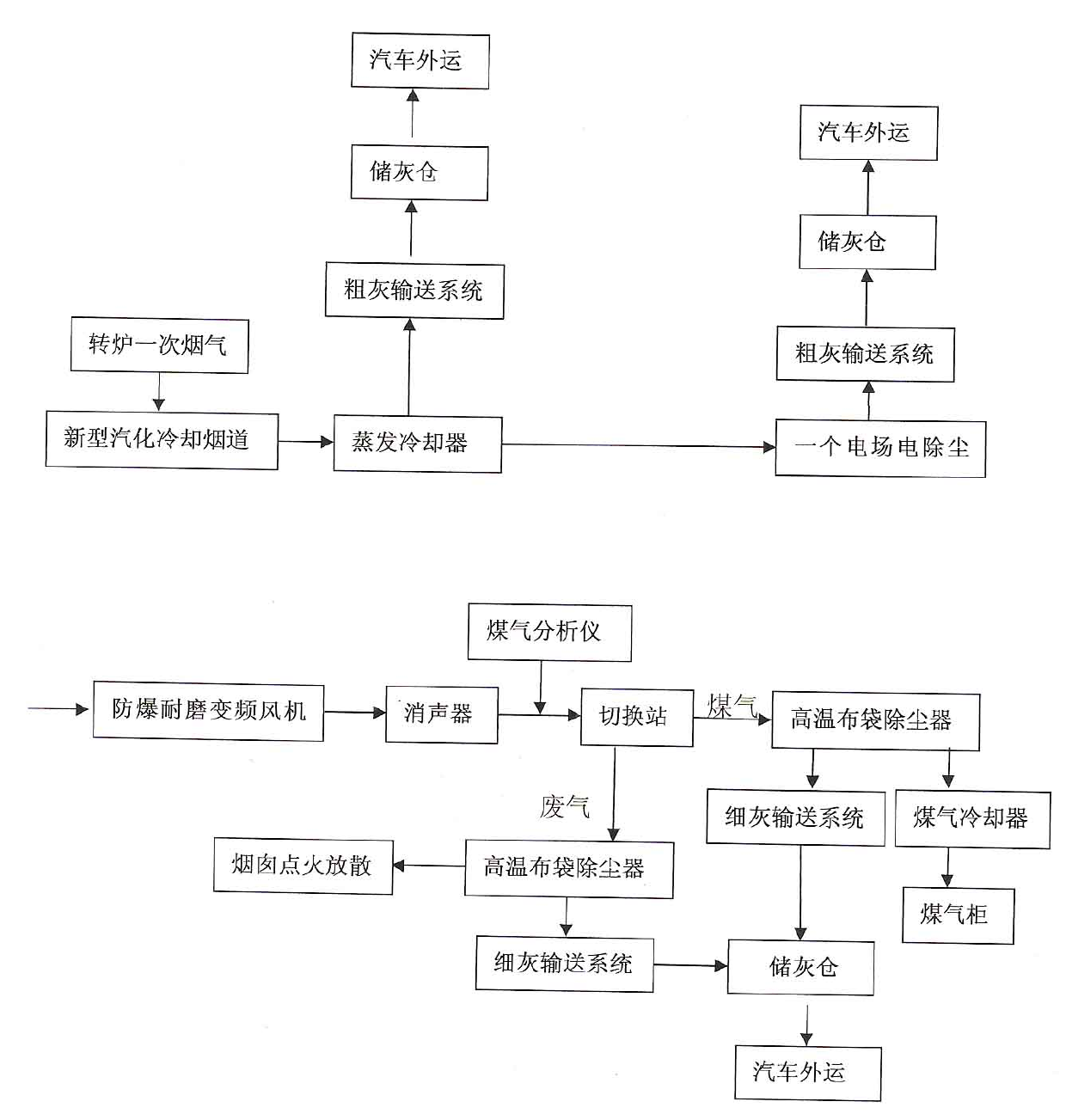

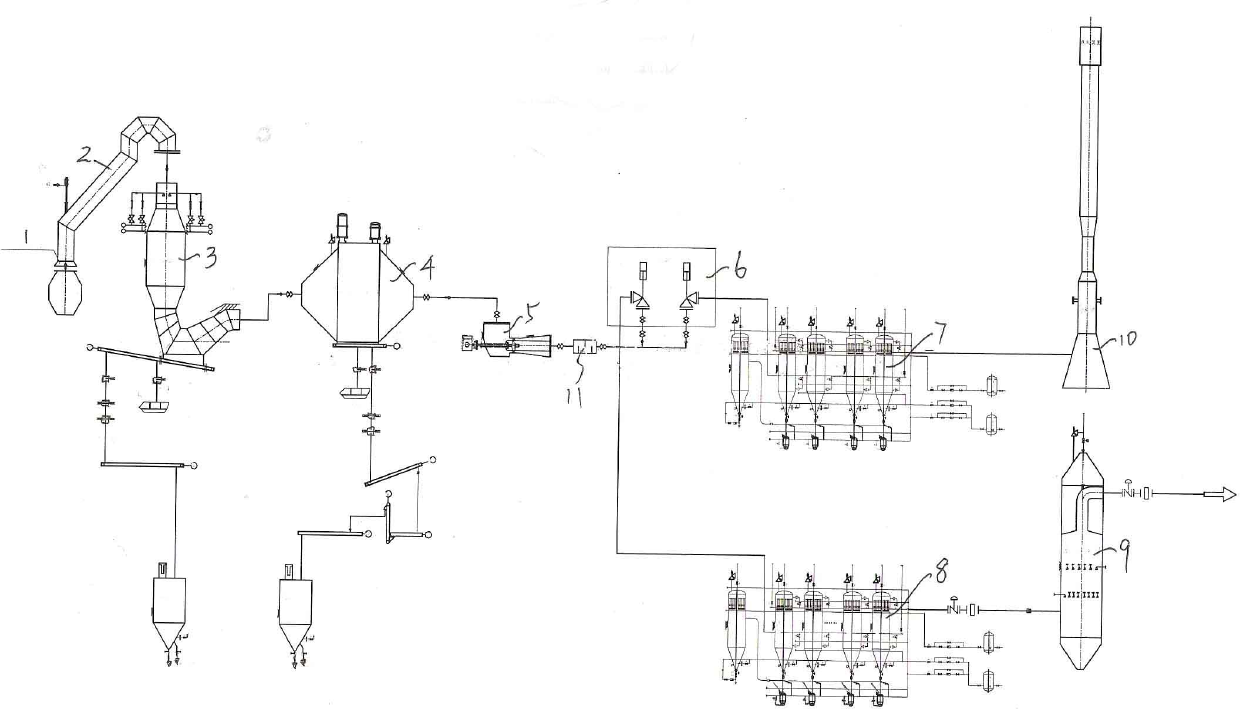

[0026] An electric bag combined type converter gas dry purification recovery system, including a fume hood 1, the fume hood is connected to the vaporization cooling flue 2, an evaporative cooling tower 3 is arranged behind the vaporization cooling flue, and a single battery cylindrical type is arranged behind the evaporative cooling tower Electrostatic precipitator 4, ID blower 5 is installed behind the electrostatic precipitator, bag-type exhaust gas dedusting device 7 and bag-type gas dedusting device 8 switching station 6 is installed behind the fan, and bag-type waste gas dedusting device 7 and bag-type gas dedusting device 8 are installed behind the switching station Device 8, a gas cooler 9 is installed behind the bag-type gas dedusting device, and an exhaust gas burner 10 is installed behind the bag-type waste gas dedusting device. A muffler 11 is arranged between the fan and the switching station.

[0027] The fume-collecting dust-collecting hood includes a skirt, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com