Air conditioning method combining solution absorbed moisture removing with compression refrigeration cycle

A technology of compression refrigeration and solution absorption, which is applied in air conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of air dehumidification and refrigeration not being realized in one step at the same time, and large external energy consumption, so as to avoid high energy consumption processing methods , Large air dehumidification and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

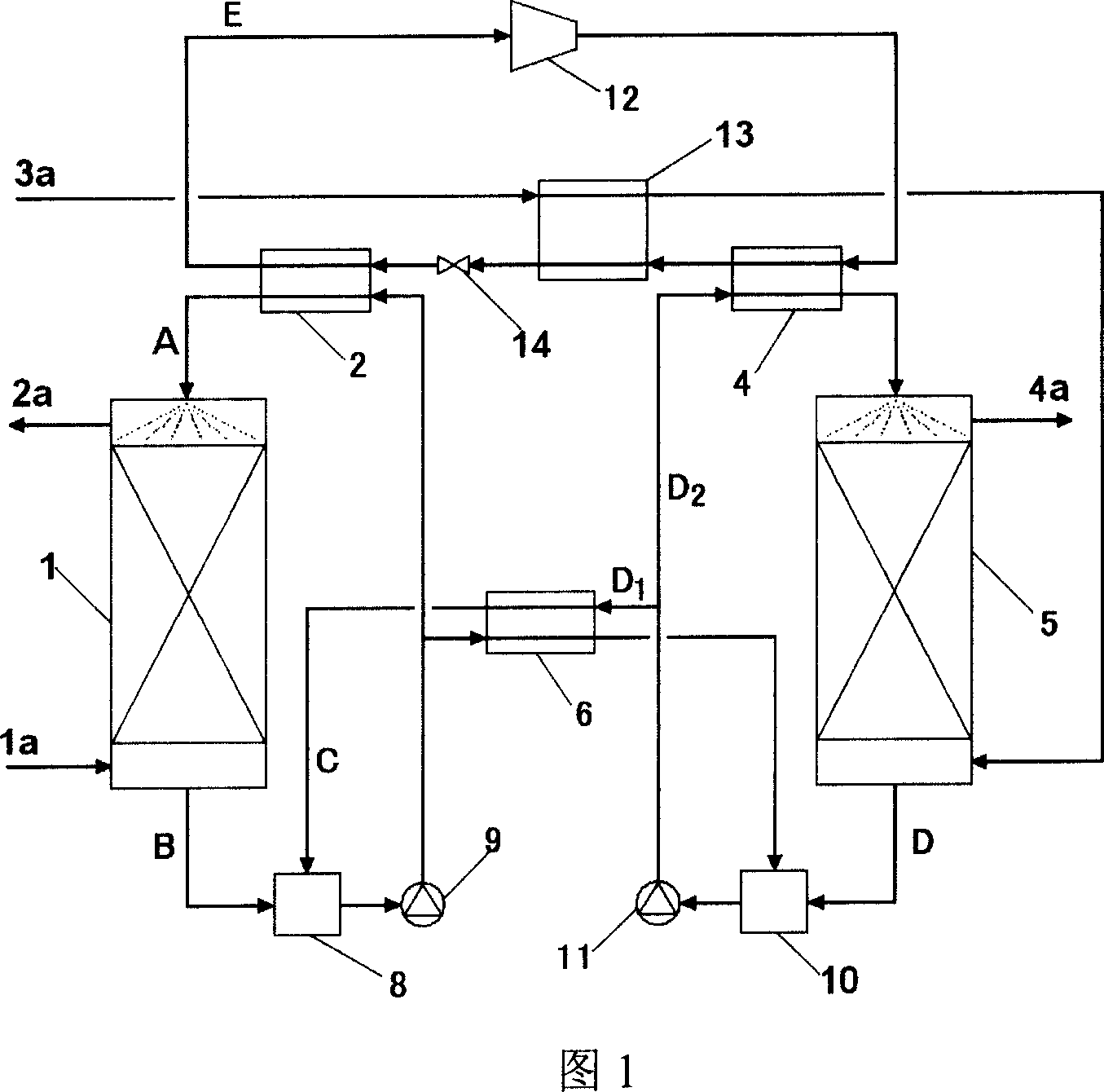

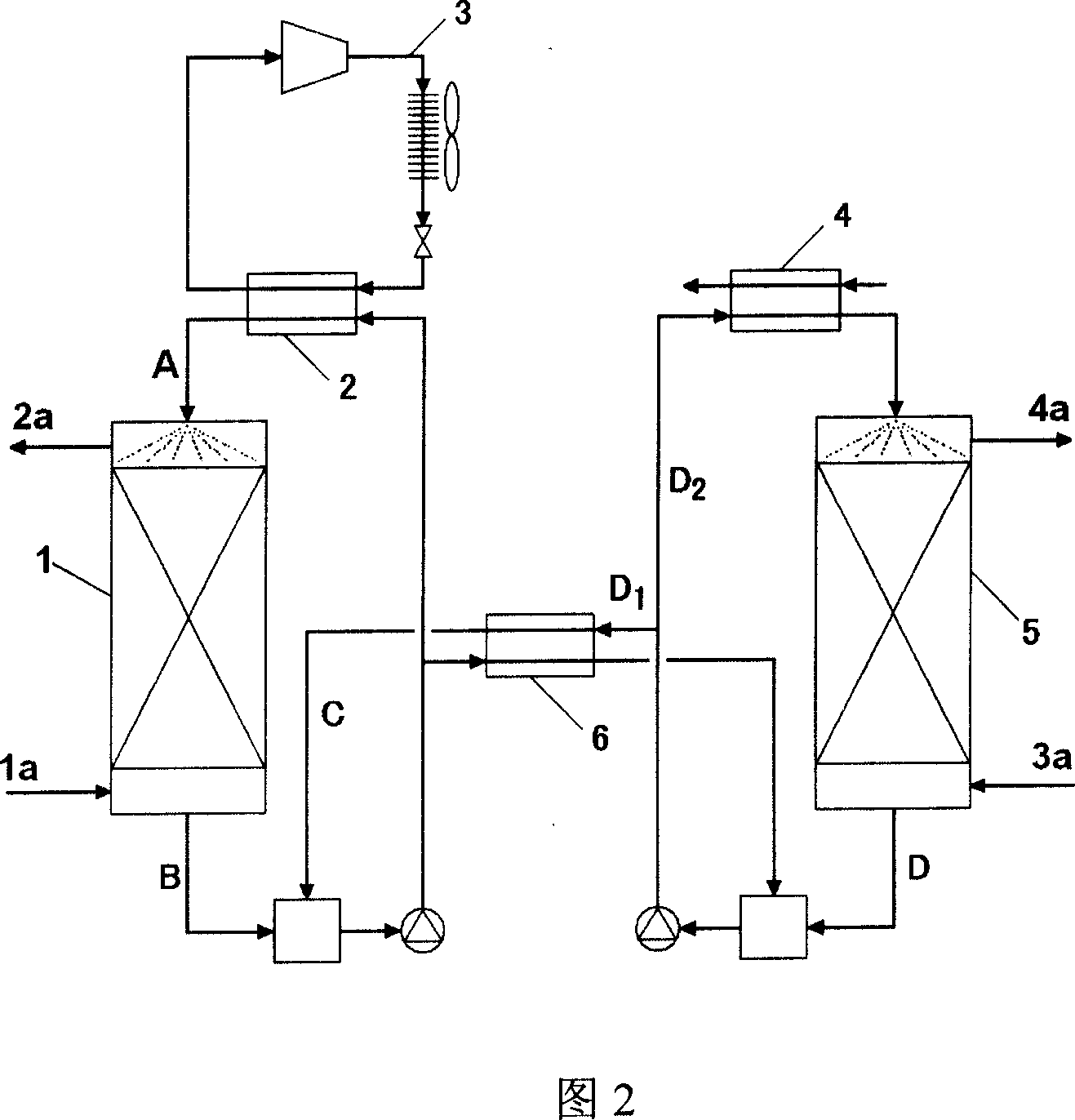

[0016] Embodiment: this embodiment is based on 40000m 3 / h of air handling capacity, compare the operating performance of the existing circulation method shown in Figure 2 and the circulation process method of the present invention shown in Figure 1, the existing circulation adopts lithium chloride solution as the dehumidification solution working medium of the solution absorption dehumidification cycle , the required absorption cooling capacity is provided by the compression refrigeration cycle with R134a as the refrigerant, and the required heat is exclusively supplied from the outside. The present invention uses the mixture of refrigerant R134a and refrigerant R141b as the refrigerant of the compression refrigeration cycle, wherein the mole fraction of R134a is 0.82, the comparison is as follows:

[0017] The parameters of each state point of the air passing through the system are shown in Table 1. Among them, state point 1a is the mixed wind of fresh air and circulating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com