White desulfurization tail smoke eliminating technology and device

A tail smoke and process technology, applied in the direction of gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of easy corrosion of condensation pipes, many condensation pipe bundles, and large amount of cold sources, so as to ensure long-term stable operation and sufficient external effects , the effect of small amount of cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

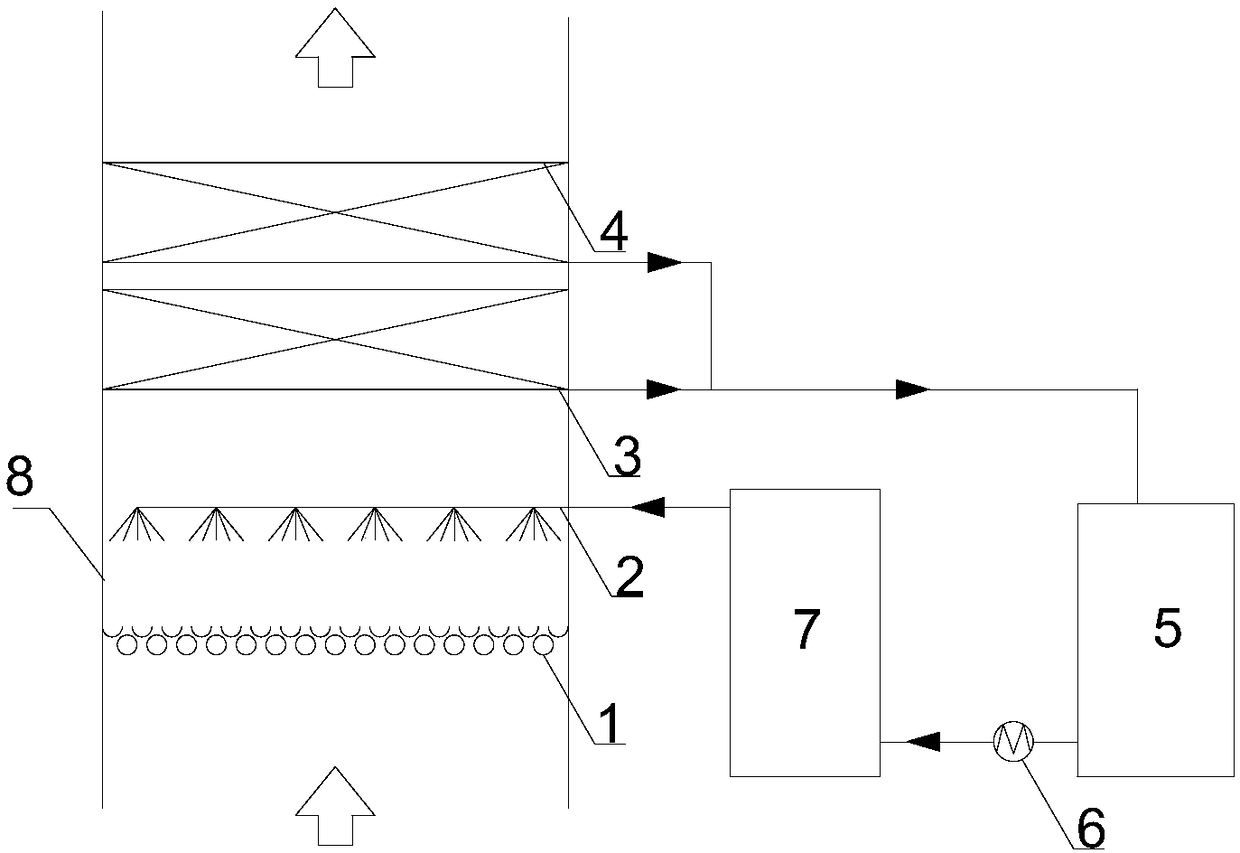

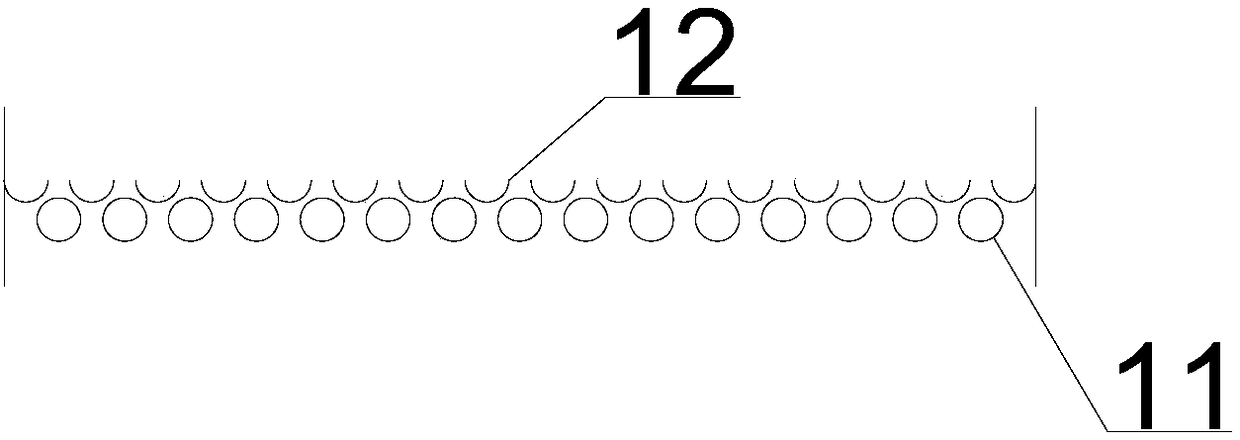

Embodiment 1

[0042] In an engineering test, the ambient temperature is 25°C, the relative humidity is 39%, and the primary air intake volume is 23162Nm 3 / h, the temperature of flue gas is 49.7°C, the moisture content of flue gas is 11.6%, and the flow rate of flue gas is 11.6%. Using the process of the present invention, a circular uniformly distributed cooling device is used to eliminate white smoke. Working condition 1: circulating water volume 20m 3 / h, the inlet water temperature is 38.2°C, the outlet water temperature is 44.5°C, the outlet flue gas temperature is 42.0°C, and the white smoke is significantly reduced; working condition 2: circulating water volume 40m 3 / h, the inlet water temperature is 38.2°C, the outlet water temperature is 42.3°C, the outlet flue gas temperature is 40.7°C, and there is only a slight white smoke at the chimney outlet; working condition 3: circulating water volume 60m 3 / h, the inlet water temperature is 38.2°C, the outlet water temperature is 39.8°C...

Embodiment 2

[0044] In an engineering test, the ambient temperature is 29°C, the relative humidity is 42%, and the primary air intake volume is 335482Nm 3 / h, the temperature of flue gas is 53.7°C, the moisture content of flue gas is 12.4%, and the flow rate of flue gas is 12.4%. Using the process of the present invention, a rhombus uniform cooling device is used to eliminate white smoke. Working condition 1: circulating water volume 30m 3 / h, the inlet water temperature is 38°C, the outlet water temperature is 44.2°C, the outlet flue gas temperature is 42.0°C, and the white smoke is significantly reduced; working condition 2: circulating water volume 60m 3 / h, the inlet water temperature is 38°C, the outlet water temperature is 43°C, the outlet flue gas temperature is 40.4°C, and there is no white smoke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com