Cooling water pipe connected net for cooling walls of soft water blast furnace

A technology of cooling water pipes and cooling walls, applied in the direction of cooling devices, etc., can solve the problems of unfavorable blast furnace shape stability and easy damage, and achieve the effects of reducing power consumption and operating costs, suppressing hazards, and avoiding burning losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

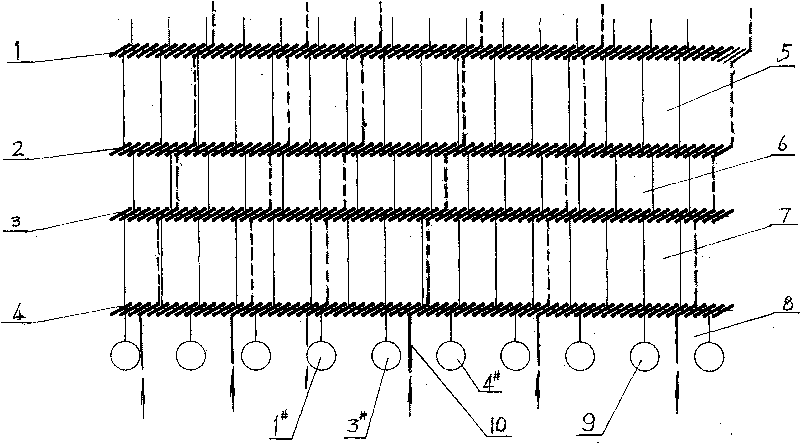

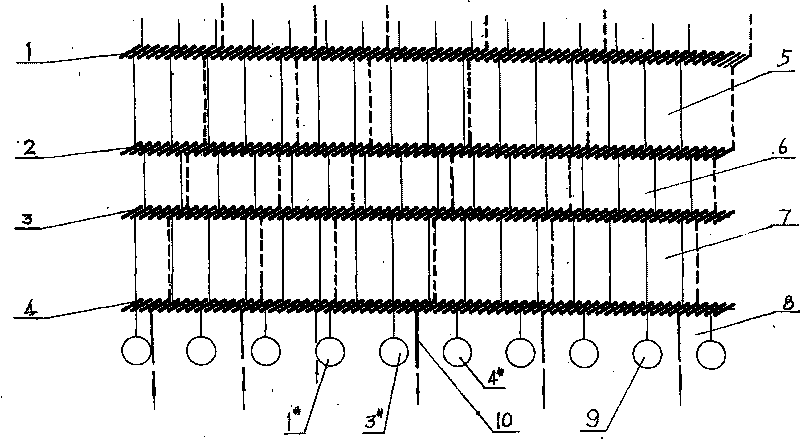

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0011] As shown in the drawings, on the soft water blast furnace wall, tuyere band staves 8, bosh staves 7, waist staves 6 and shaft staves 5 are installed from bottom to top, which are the same as the prior art. Each layer of staves is composed of dozens of staves, and each stave is connected with cooling water pipes outside the furnace with a number greater than 1 (generally greater than or equal to 4), that is, there are more than two adjacent layers of staves 5 1 is connected to the first cooling water pipe 1 outside the furnace, and the second cooling water pipe 2 outside the furnace whose number is greater than 1 is connected between the furnace stave 5 and the bosh stave 6, and the furnace stave 6 is connected to the bosh stave 7 There is a third external cooling water pipe 3 with a quantity greater than 1 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com