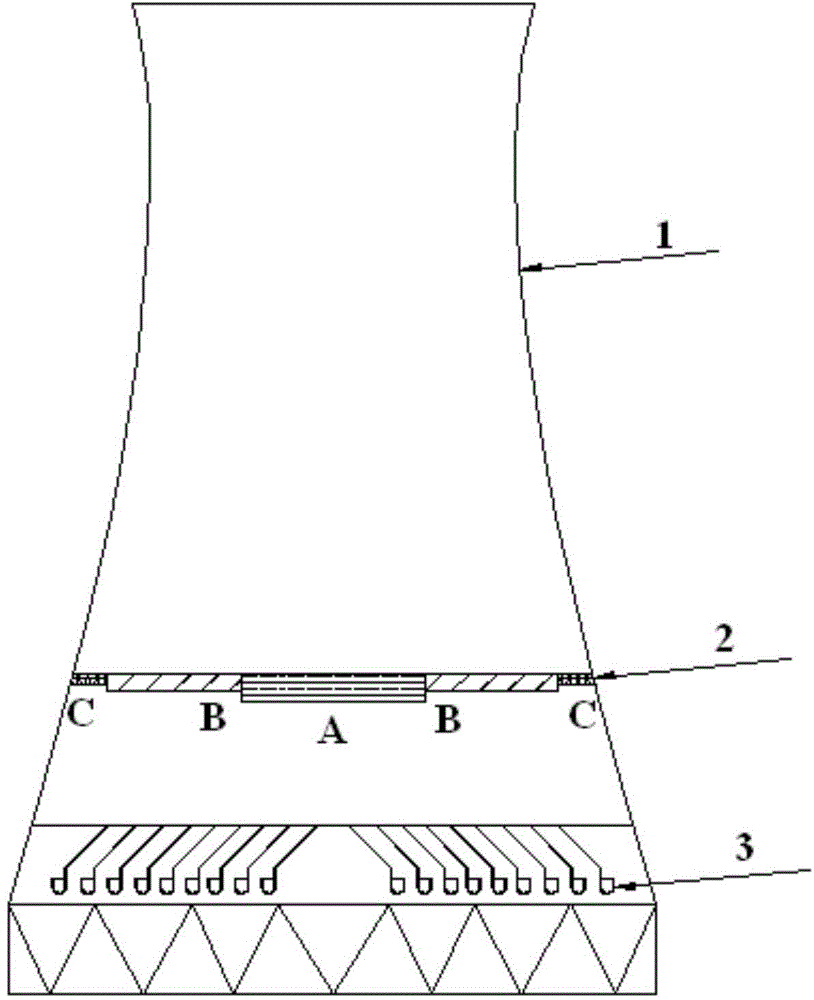

Non-uniform water distribution system for high-position water collecting cooling tower

A high-level water collection and water distribution system technology, applied in water shower coolers, lighting and heating equipment, heat exchanger types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

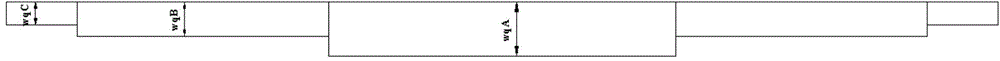

[0027] Area A range: Water spray density wqA=1.073q;

[0028] Area B range: Water spraying density wqB=q;

[0029] Area C range: Water spray density wqC = 0.8q.

Embodiment 2

[0031] Area A range: Water spray density wqA=1.12q;

[0032] Area B range: Water spray density wqB=0.9q;

[0033] Area C range: Water spray density wqC = 0.75q.

[0034] In the present invention, outside air enters the high-level water-receiving cooling tower and passes through the water-collecting area. Due to the certain guiding effect of the water-collecting device area on the air, the air flow rate in the central area of the high-level water-receiving cooling tower is the largest, and the air flow rate in the peripheral area is the smallest. Since the air velocity in the middle area is the highest and the cooling water temperature in the middle area is still far from the cooling limit wet-bulb air temperature, that is, the cooling capacity of the middle area still has room for improvement. In order to make use of its cooling capacity as much as possible, the spraying water density in the middle area is increased.

[0035] Due to insufficient air flow in the periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com