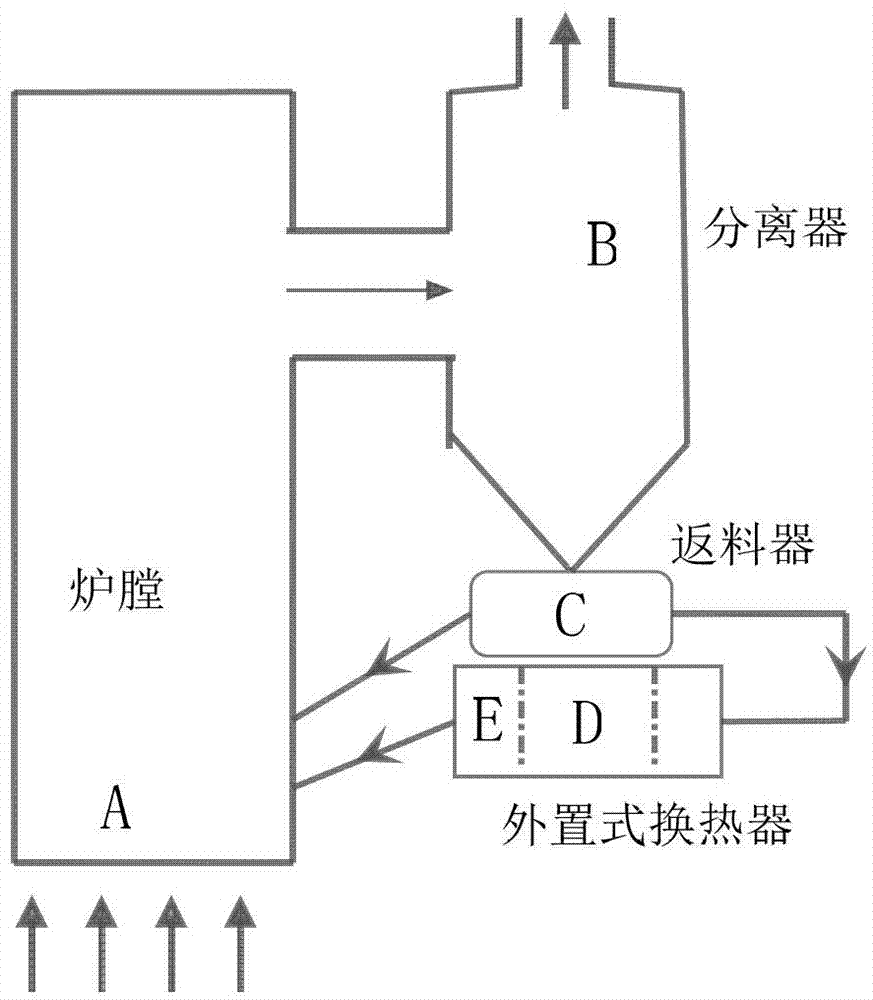

Method for discharging slags from circulating fluidized bed boiler based on external heat exchanger

A circulating fluidized bed and heat exchanger technology, applied in the field of electric power design, can solve single problems, achieve low slag discharge temperature, reduce slag discharge temperature, and reduce cooling water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

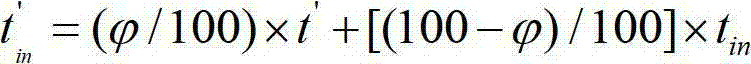

Method used

Image

Examples

specific Embodiment approach

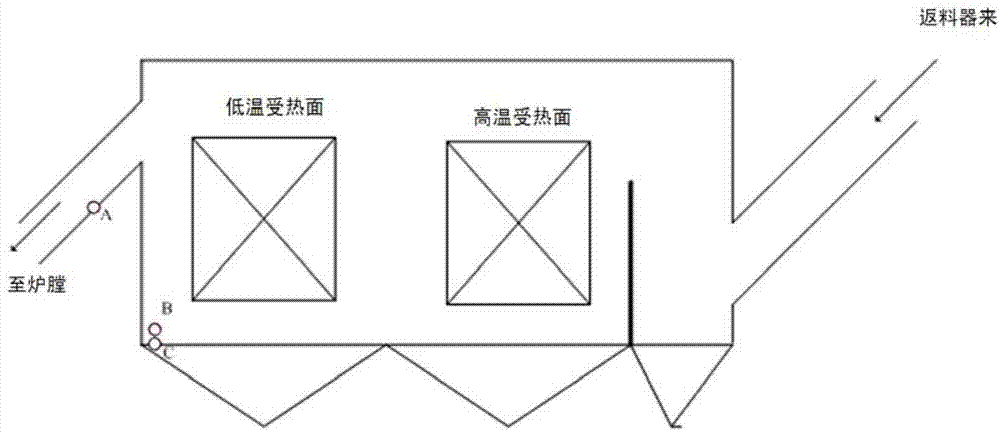

[0047] (1) The number of slag outlets of the external heat exchanger is determined according to the layout of the external heat exchanger. When the left and right are arranged symmetrically, one can be arranged on the left and right respectively, and they are arranged in the external heat exchanger with a lower steam temperature on the heating surface. .

[0048] (2) There are three types of slag discharge for external heat exchangers:

[0049] 1.1 A slag discharge port is set at the channel from the external heat exchanger to the furnace, and the circulating ash is discharged to the slag cooler through the slag discharge pipe, and a slag discharge valve is installed on the slag discharge pipe. See attached figure 2 Point A.

[0050] 1.2 Set a slag outlet at the bottom of the downstream side wall of the low-temperature heating surface of the external heat exchanger, and set a conical valve to control the discharge of the circulating ash through the conical valve, and discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com