Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

A low-alloy steel and slab continuous casting technology, which is applied in the field of metal continuous casting slab cooling and surface quality control, can solve the problems such as the inability to completely eliminate corner transverse crack defects, eliminate corner transverse crack defects, and improve cooling uniformity. The effect of good ductility and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

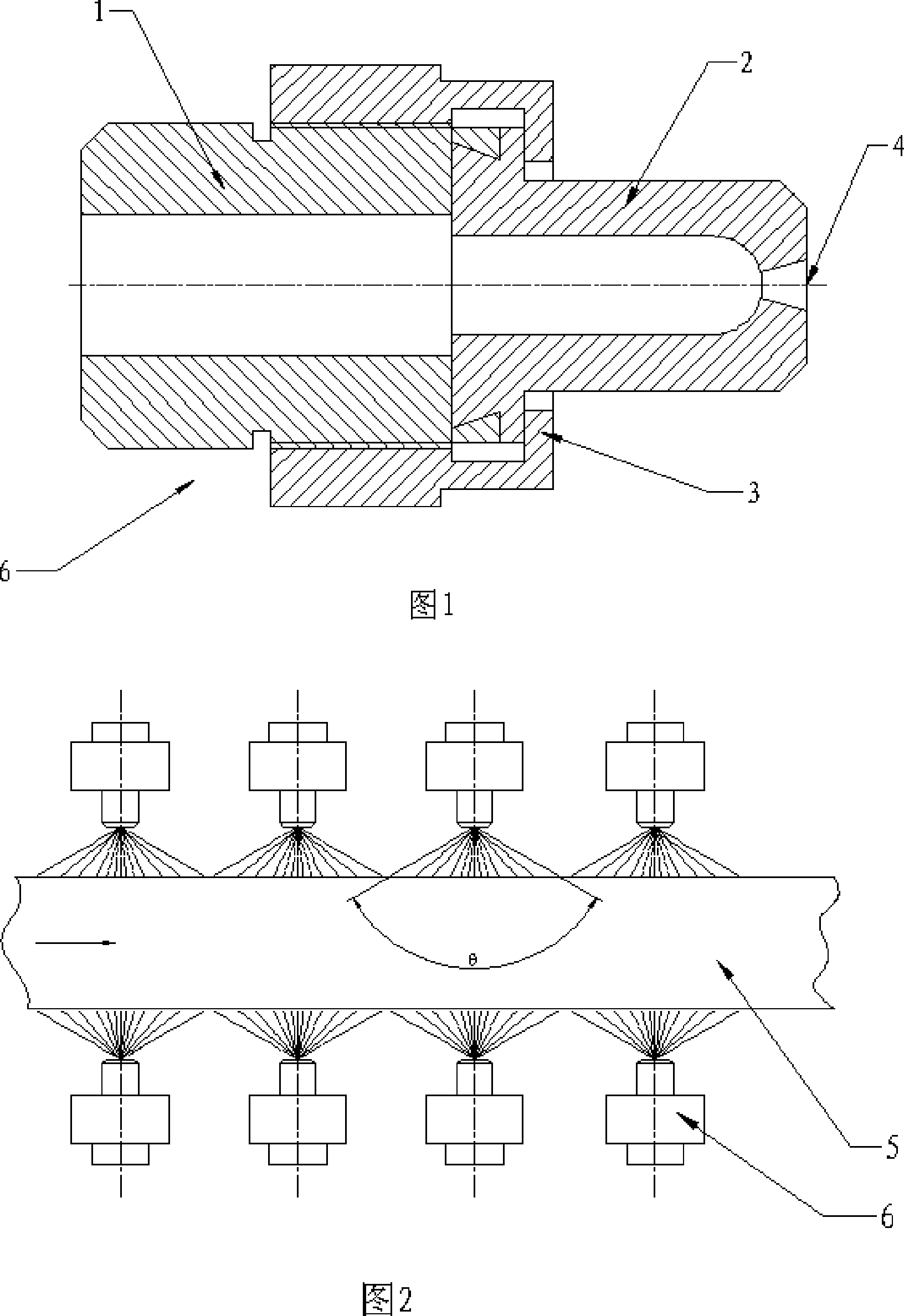

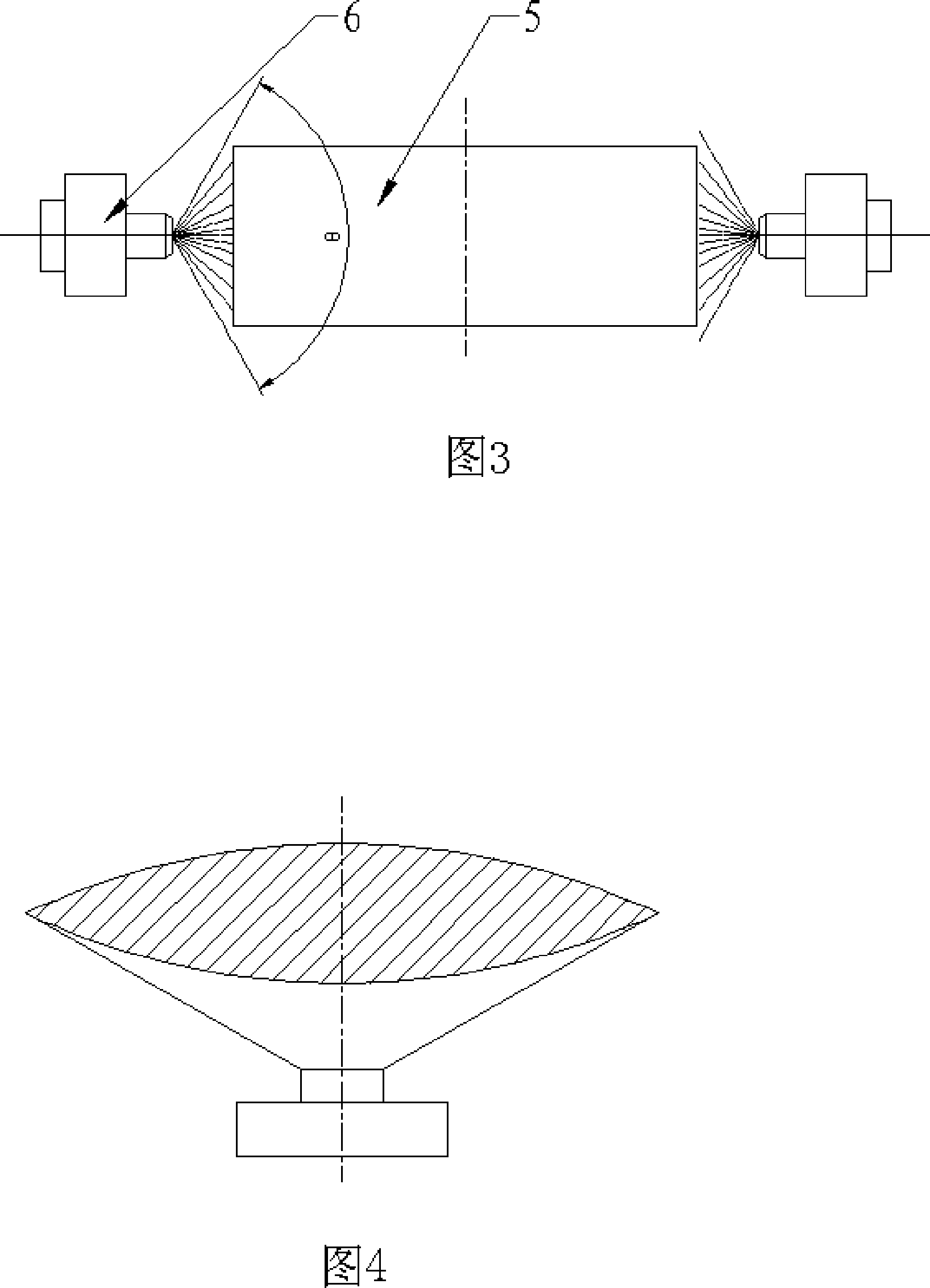

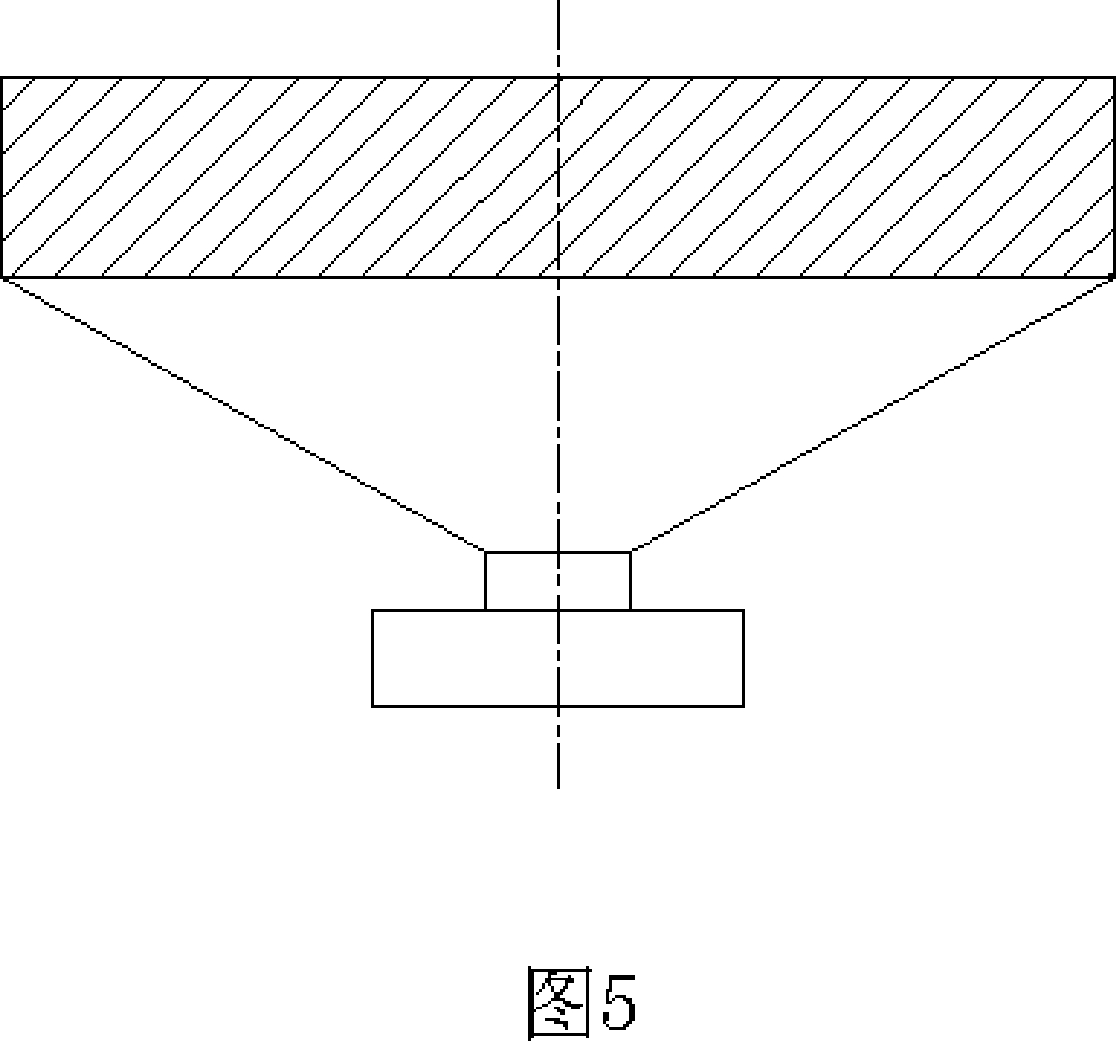

[0027] A converter steelmaking plant adopts the technology of the present invention to control the transverse crack defect at the corner of the P510L steel billet for automobile beam plate. The chemical composition of P510L steel except Fe and a small amount of impurities is shown in Table 1. In continuous casting production, the nozzle structure shown in Figure 1 is used, which is composed of three parts: nozzle 2, coupling screw 1 and coupling nut 3, and the nozzle is designed according to the nozzle pressure-flow characteristics shown in Table 2. The foot roller section is narrow See Figure 2 and Figure 3 for the schematic diagrams of the layout of the surface nozzles along the longitudinal and transverse directions. Before casting, the width of the slab is set to 1050mm, the thickness of the slab is set to 200mm, the casting speed of the casting machine is 1.40m / min during continuous casting, and the water volume of the narrow surface of the foot roll section is set to 67....

Embodiment 2

[0033]A converter steelmaking plant adopts the technology of the present invention to control the transverse crack defect at the corner of the P510L steel billet for automobile beam plate. The chemical composition of P510L steel except Fe and a small amount of impurities is shown in Table 1. During continuous casting production, the same nozzles as in Example 1 are used, and the layout schematic diagrams of the narrow surface nozzles of the foot roll section along the longitudinal and transverse directions are shown in Figure 2 and Figure 3 . Before casting, the width of the slab is set to 1300mm, the thickness of the slab is set to 200mm, the casting speed of the casting machine is 0.80m / min during continuous casting, and the water volume of the narrow surface of the foot roll section is set to 45.2L / min. After the casting is completed, the surface inspection and low-magnification inspection of the produced slab are carried out. The inspection shows that the depth of the vibr...

Embodiment 3

[0035] A converter steelmaking plant adopts the technology of the present invention to control the transverse crack defect at the corner of the P590L steel billet for automobile beam plate. The chemical composition of P590L steel except Fe and a small amount of impurities is shown in Table 3. During continuous casting production, the same nozzles as in Example 1 are used, and the layout schematic diagrams of the narrow surface nozzles of the foot roll section along the longitudinal and transverse directions are shown in Figure 2 and Figure 3 . Before casting, the width of the slab is set to 1100mm, the thickness of the slab is set to 200mm, the casting speed of the casting machine is 1.20m / min during continuous casting, and the water volume of the narrow surface of the foot roll section is set to 59.8L / min. After the casting is completed, the surface inspection and low-magnification inspection of the produced slab are carried out. The inspection shows that the depth of the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com