Patents

Literature

33results about How to "Increase waste heat power generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

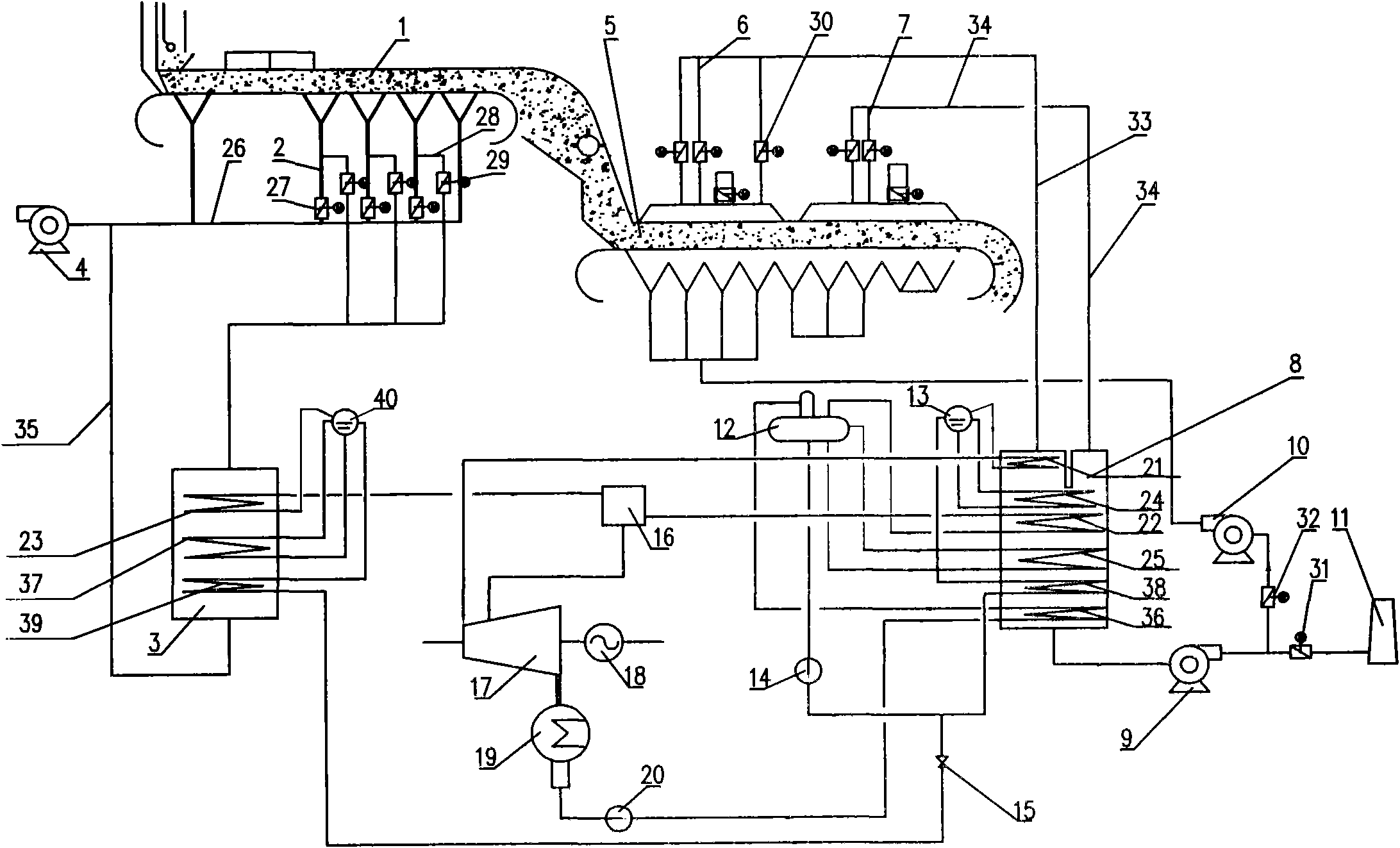

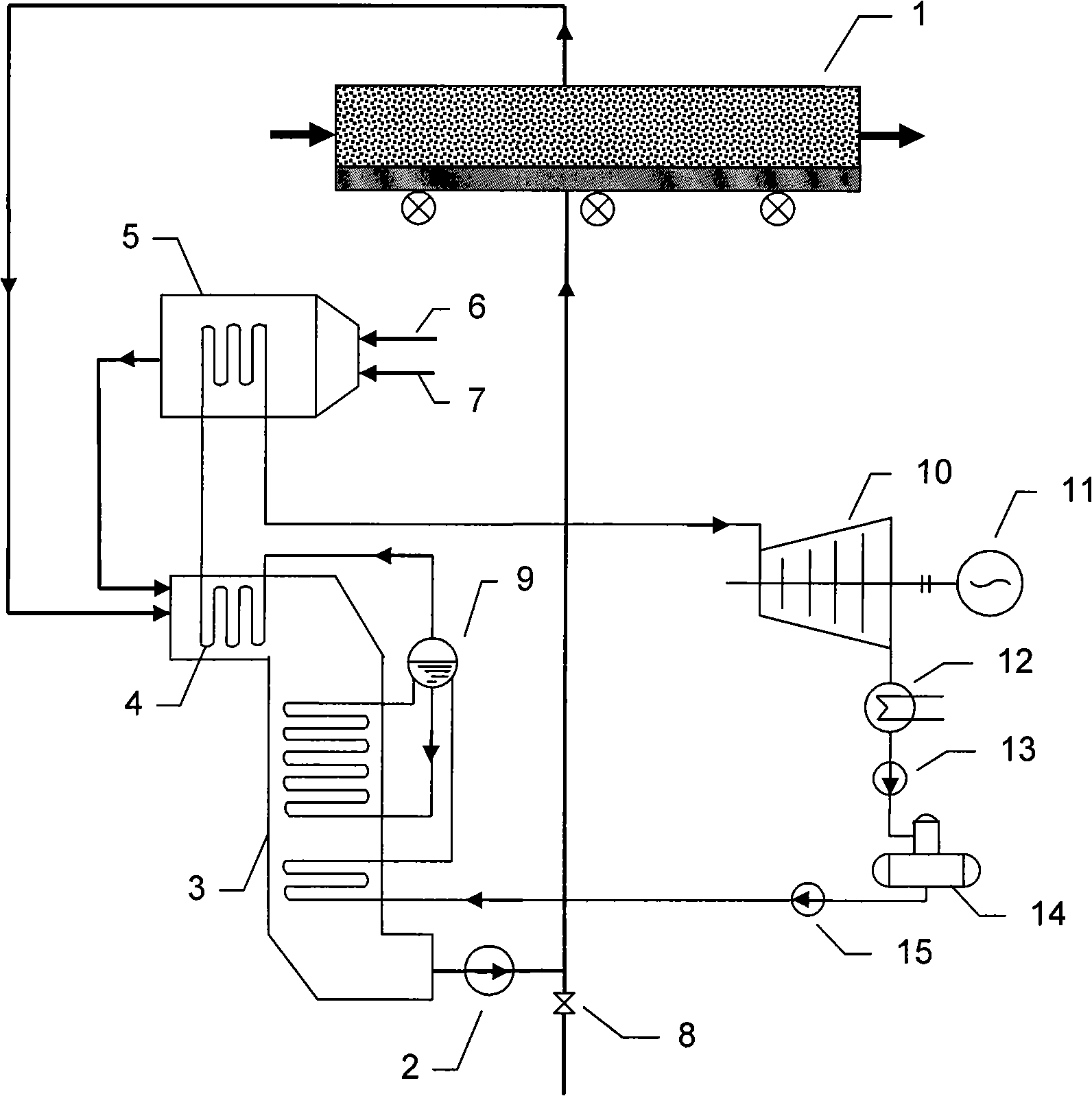

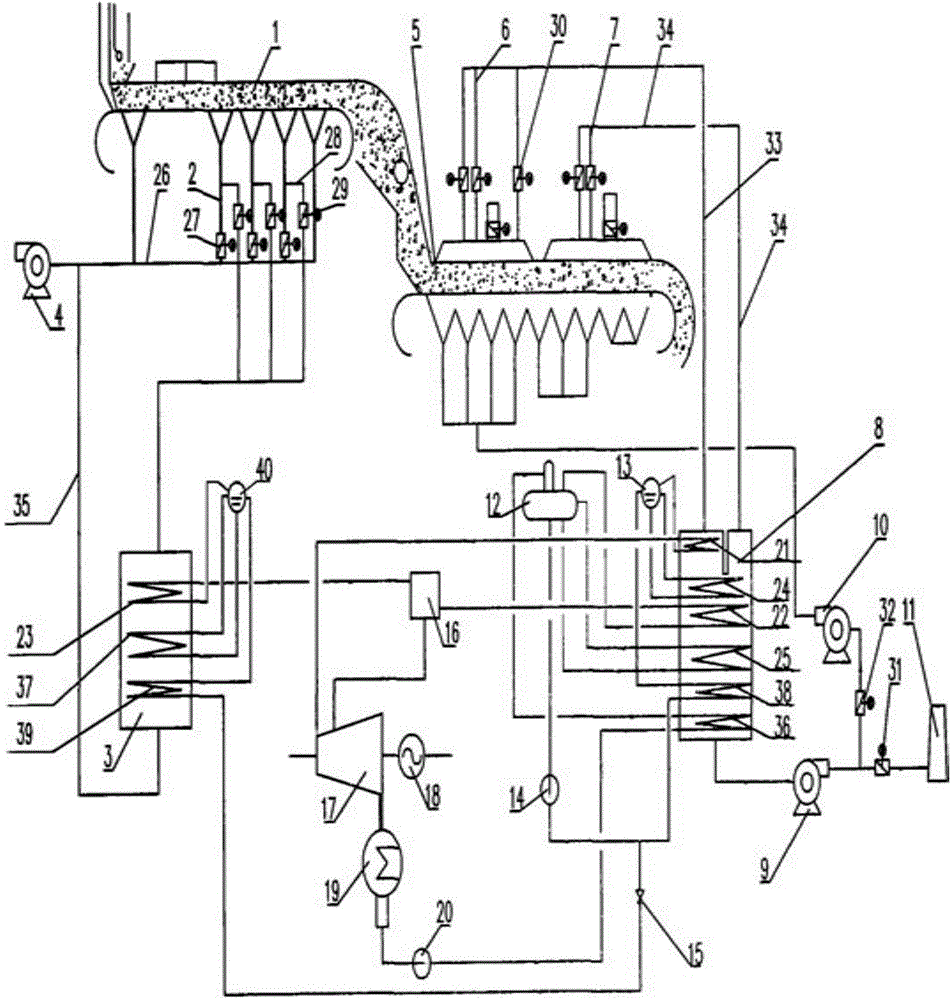

System and method for using sintering waste heat to generate electricity

InactiveCN101806230AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityExhaust fumes

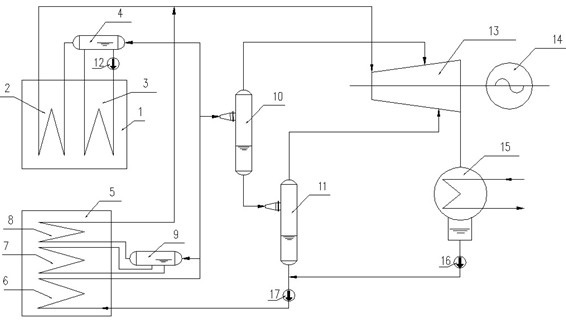

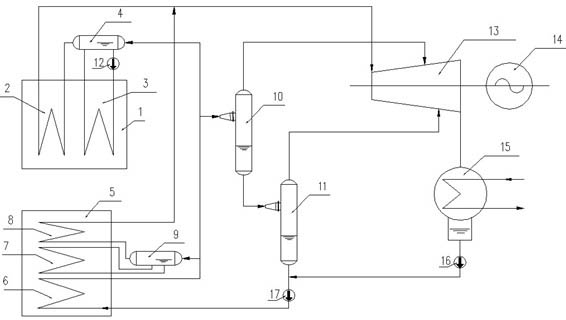

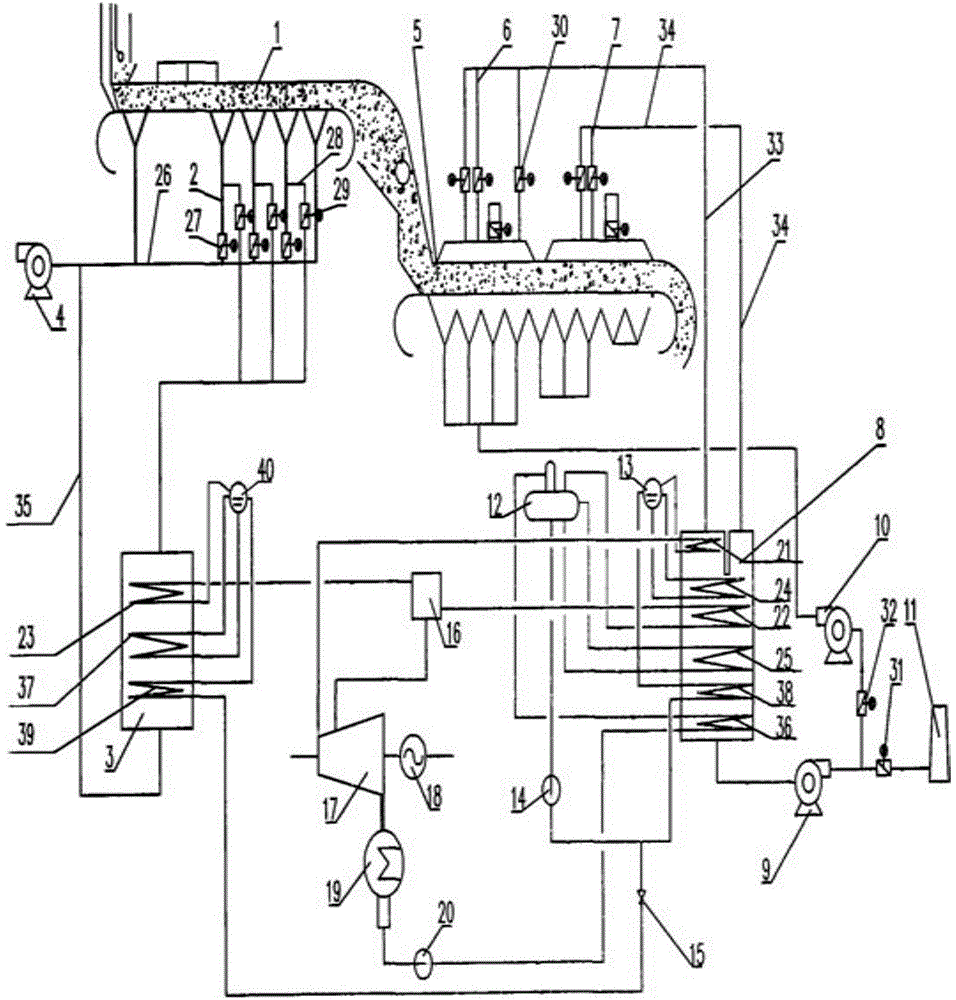

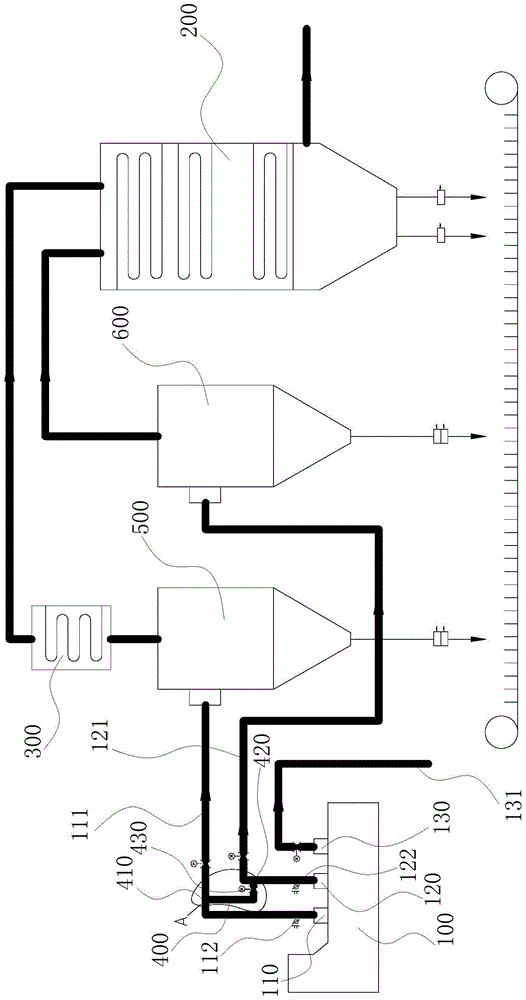

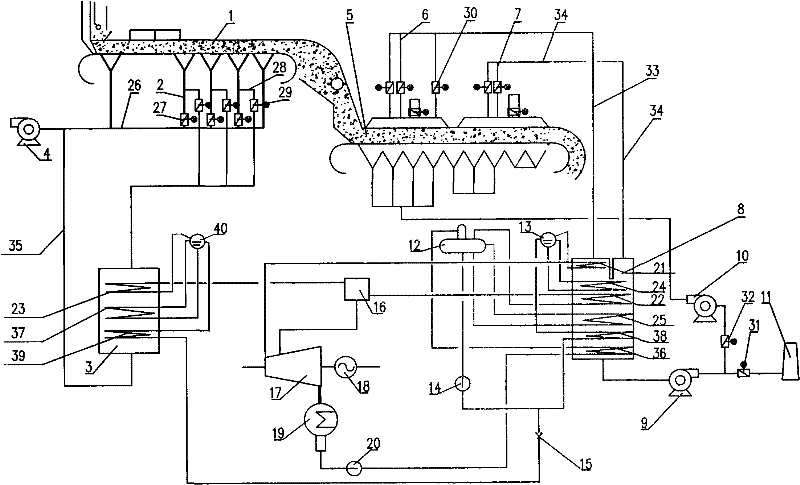

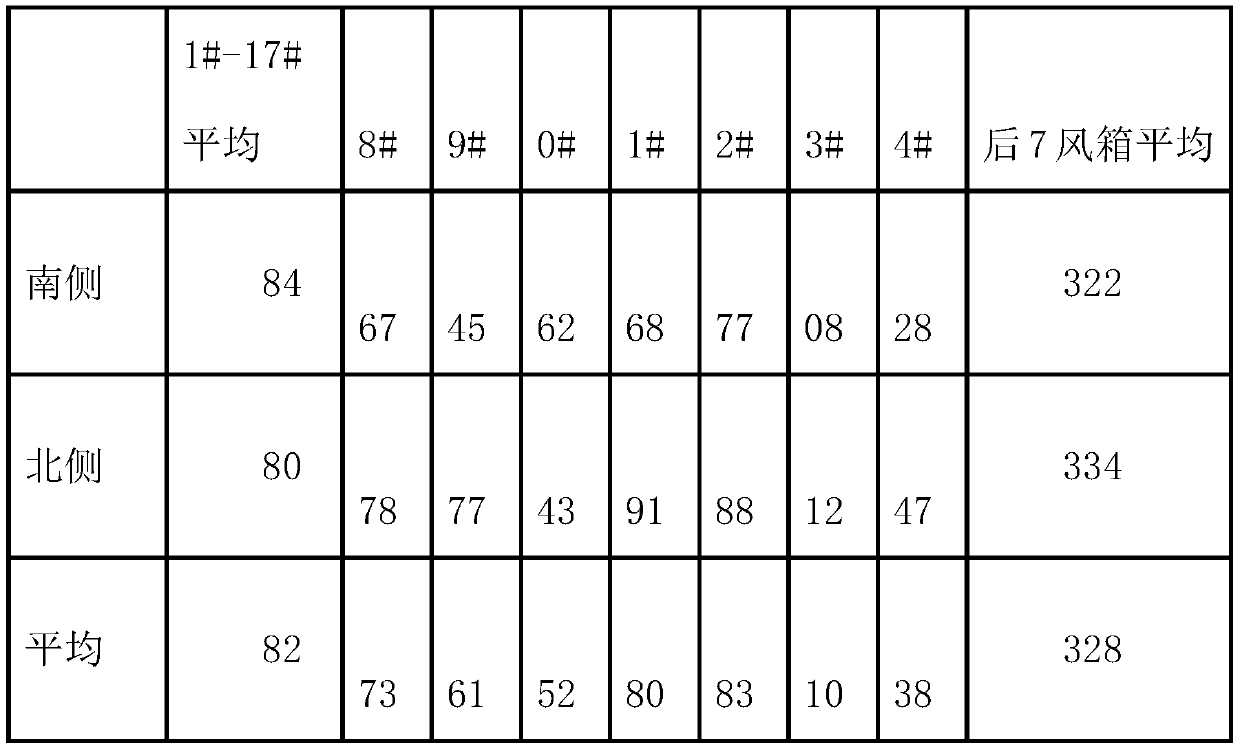

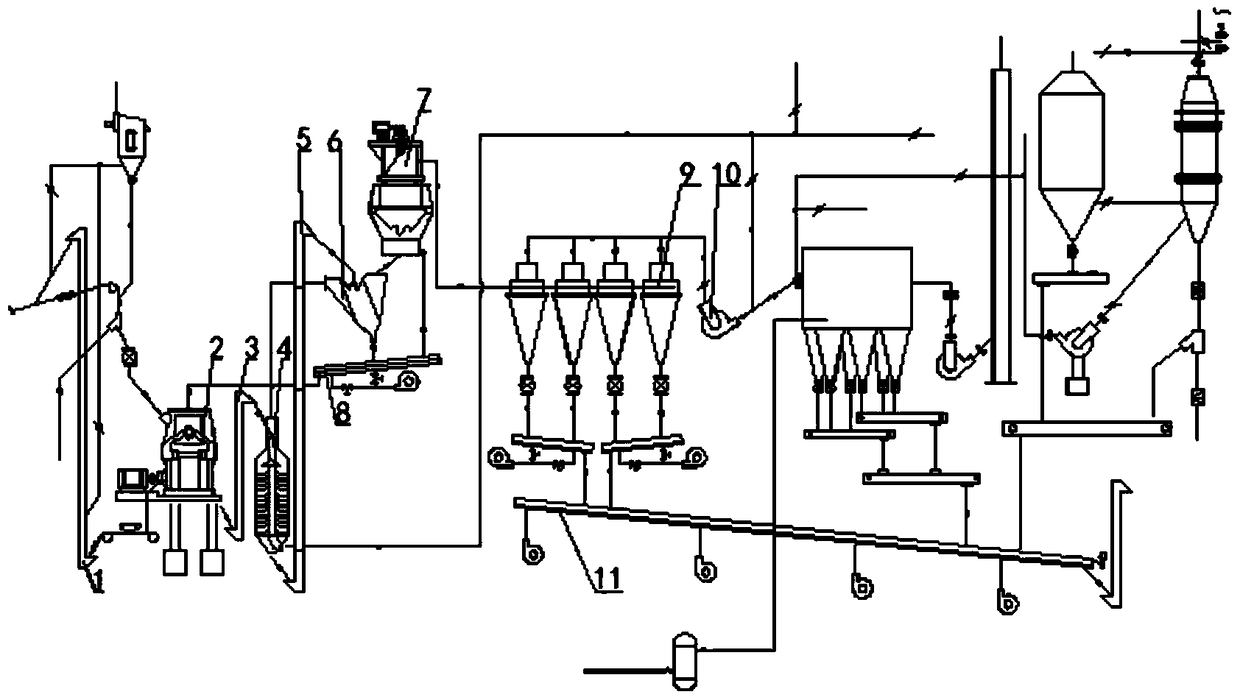

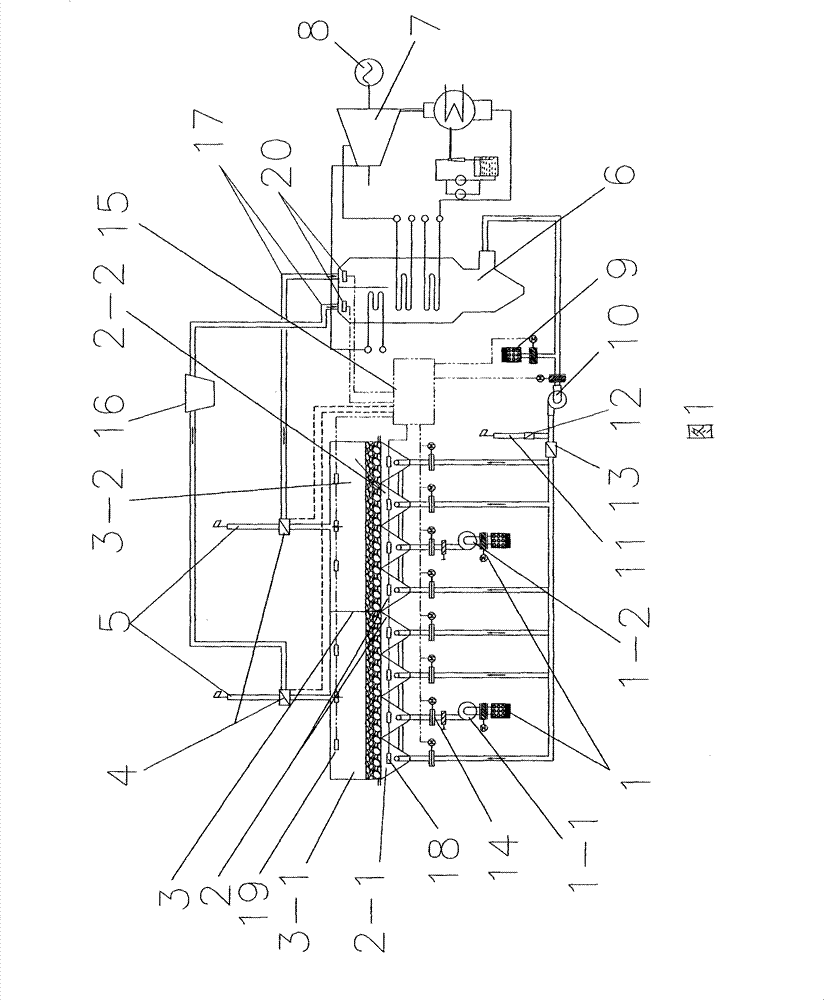

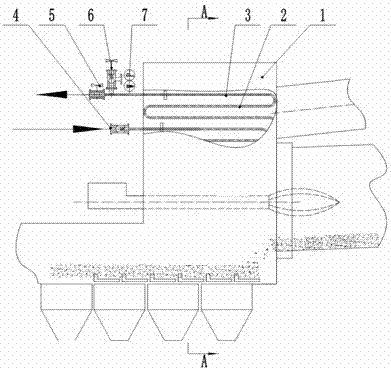

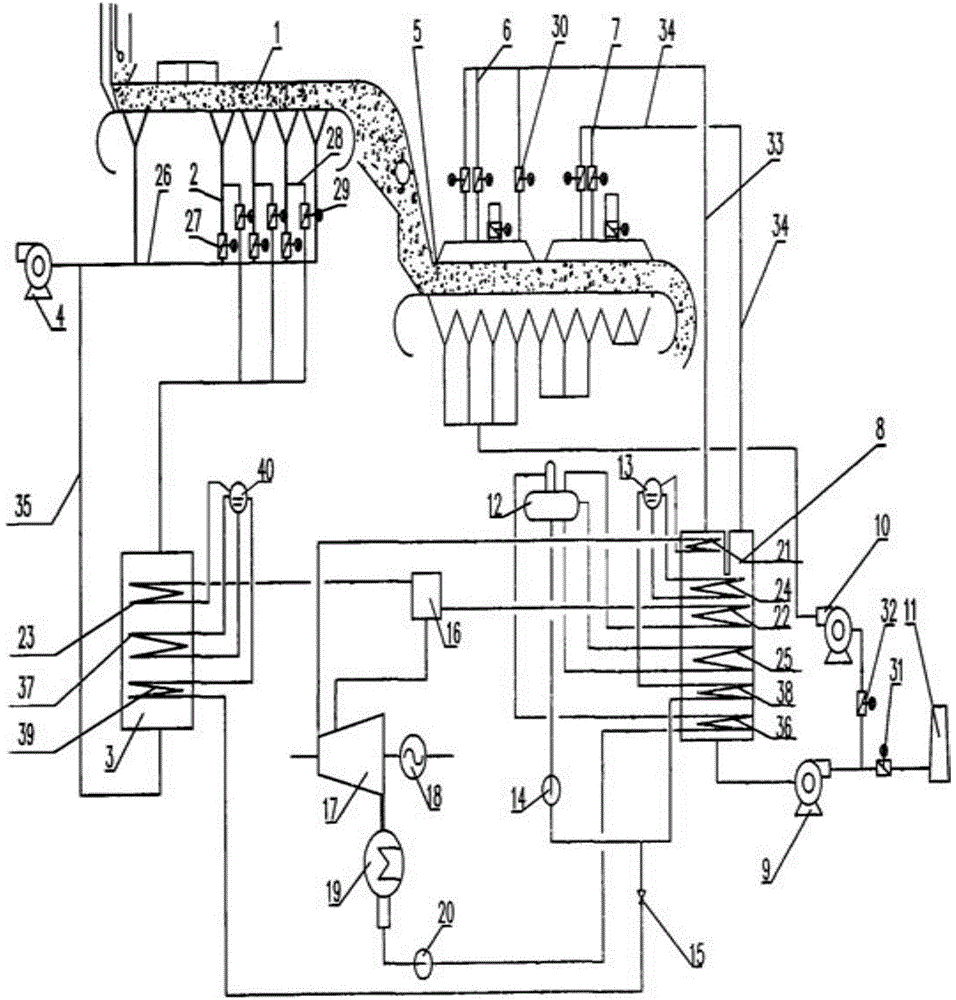

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of the ring cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

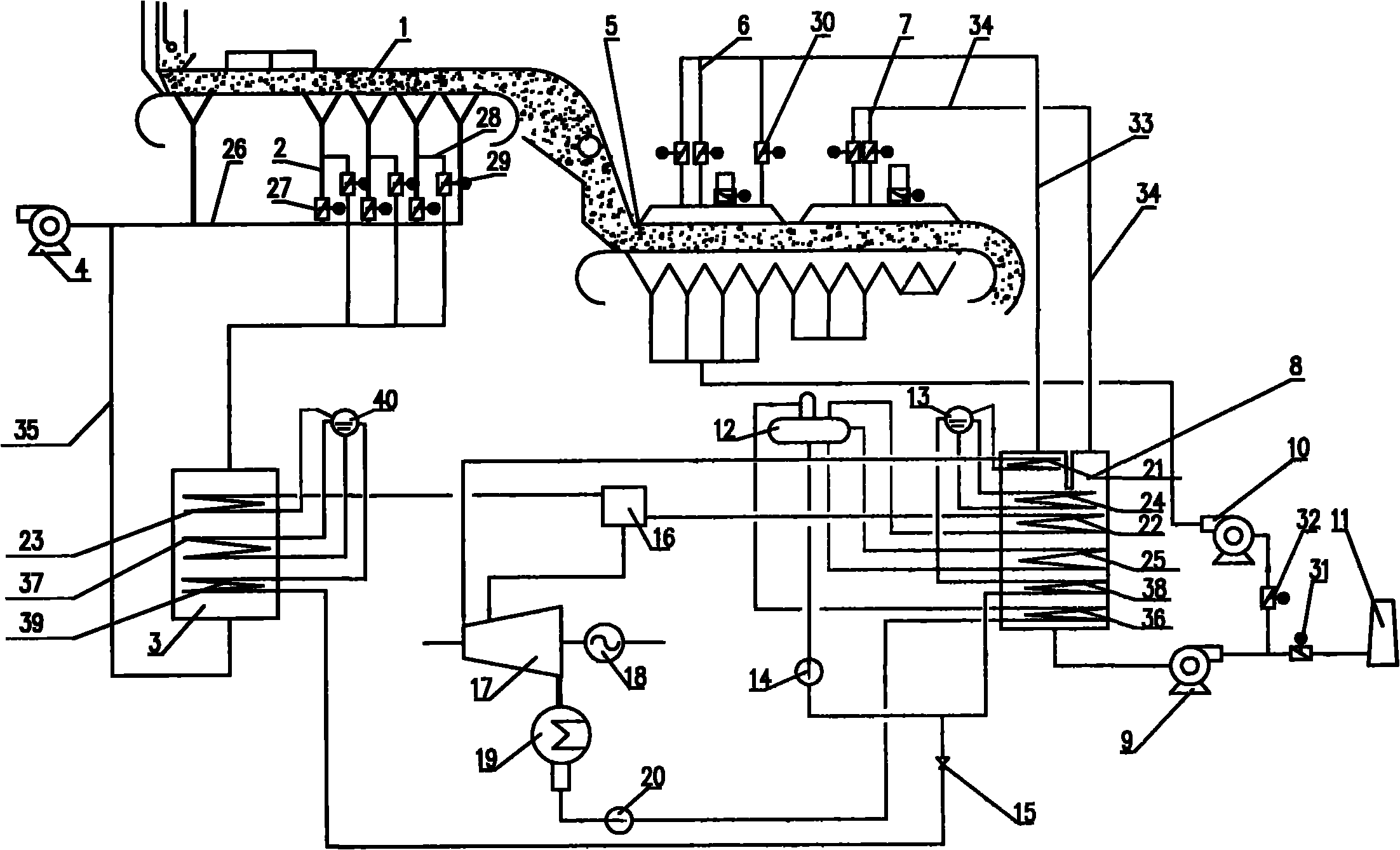

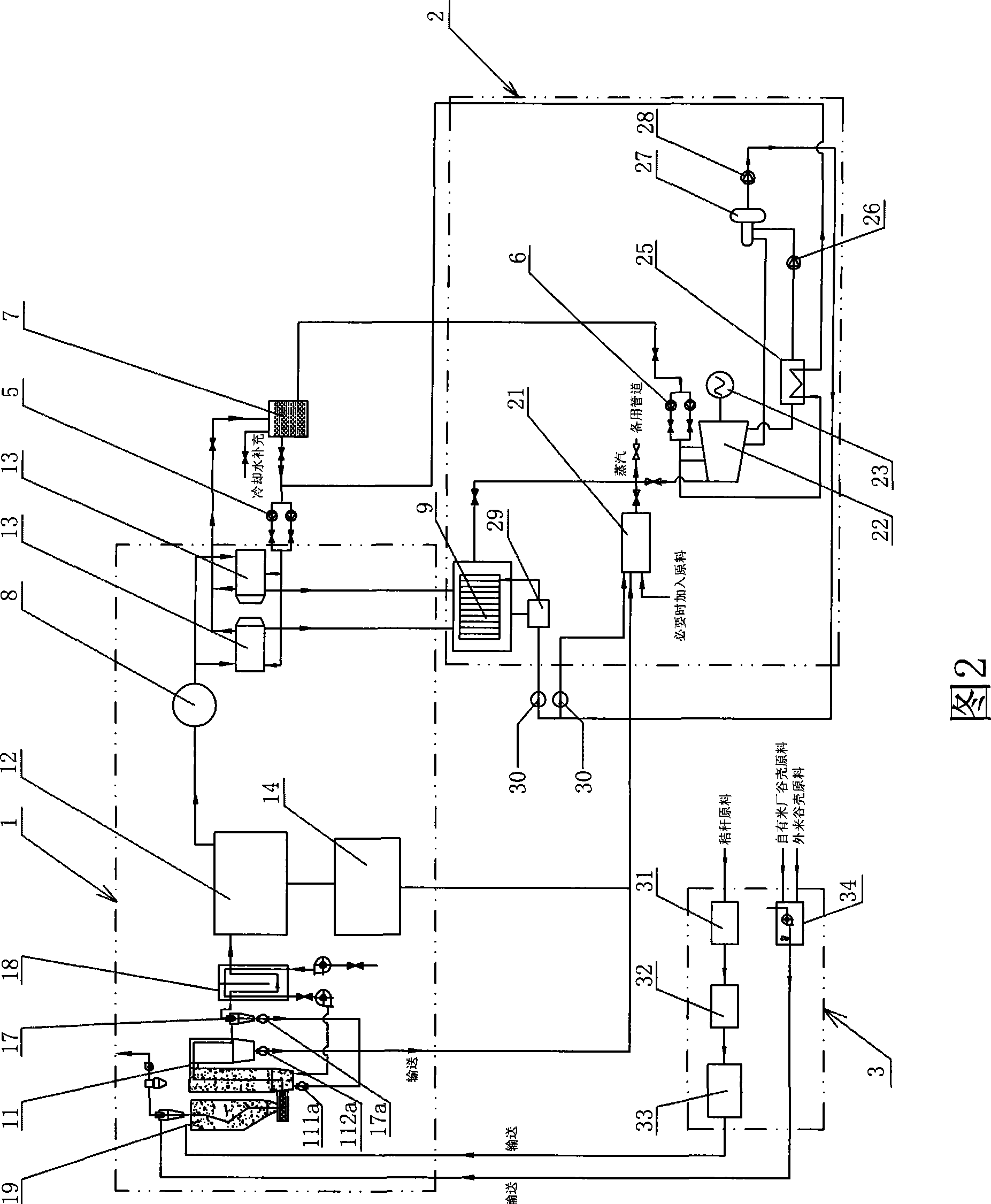

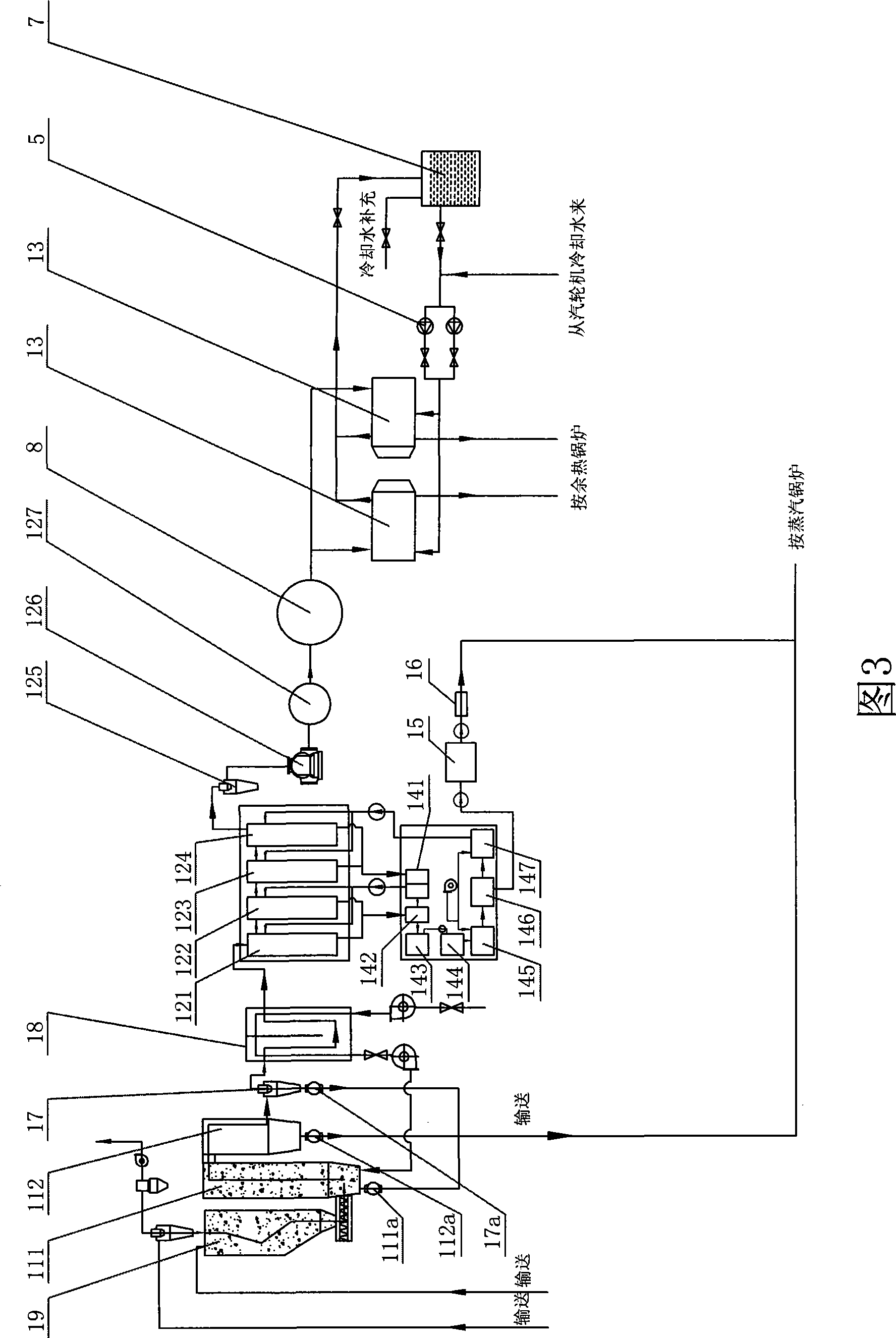

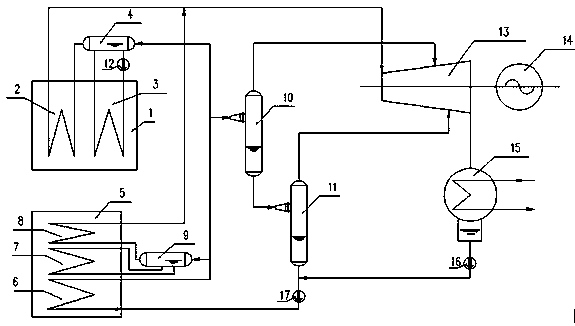

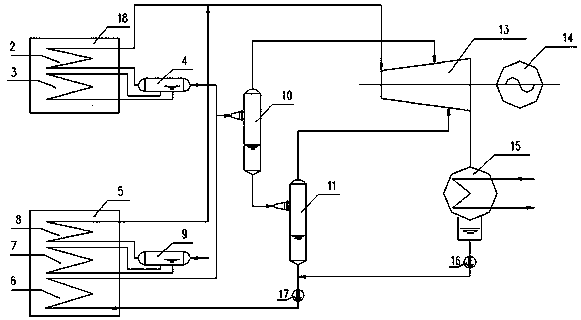

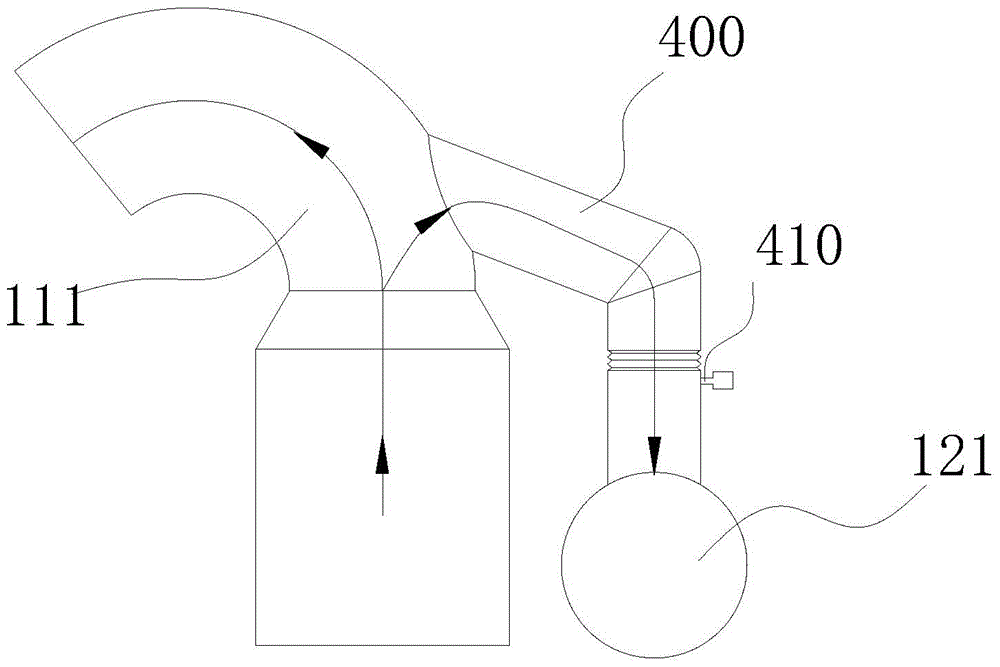

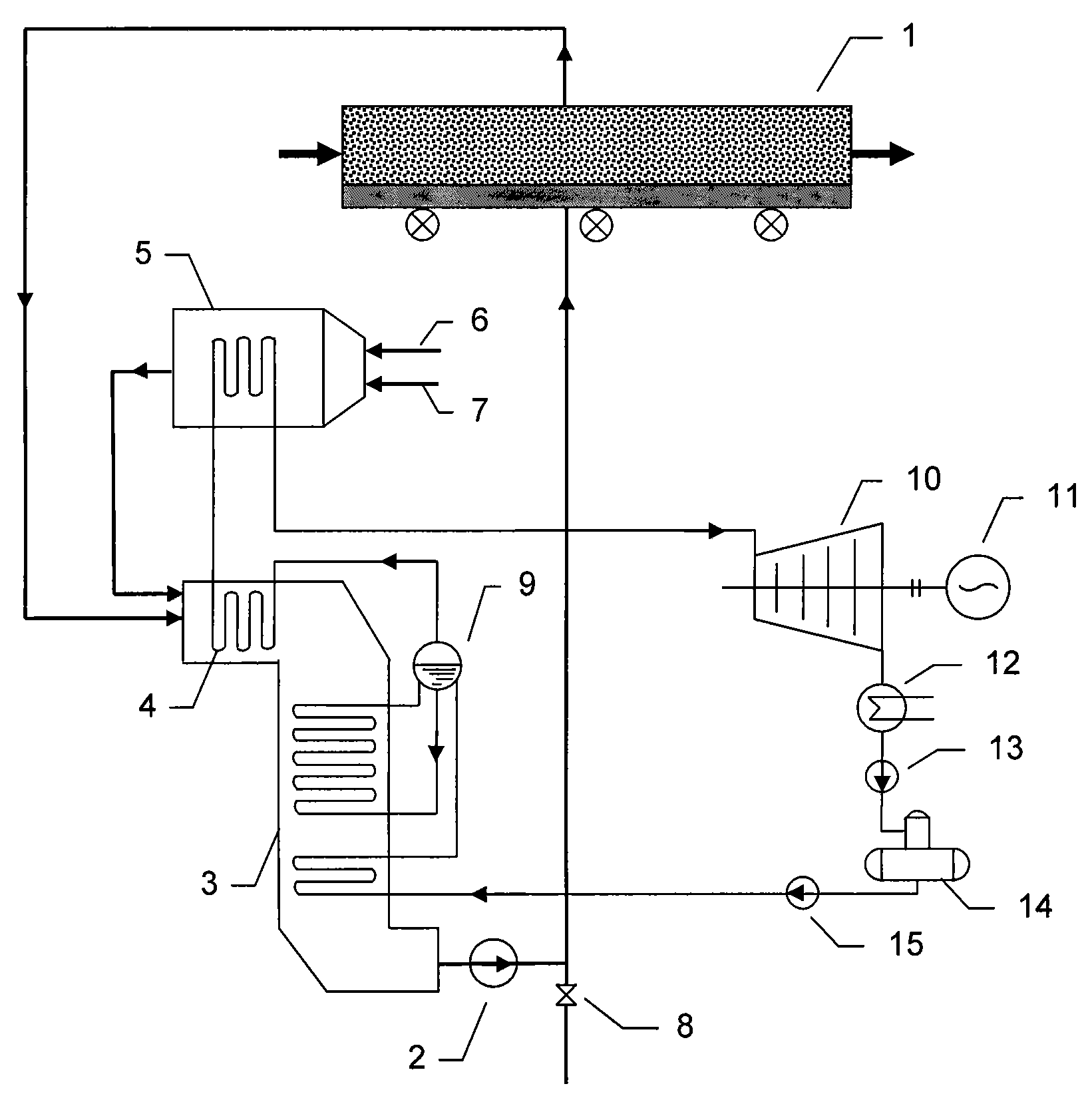

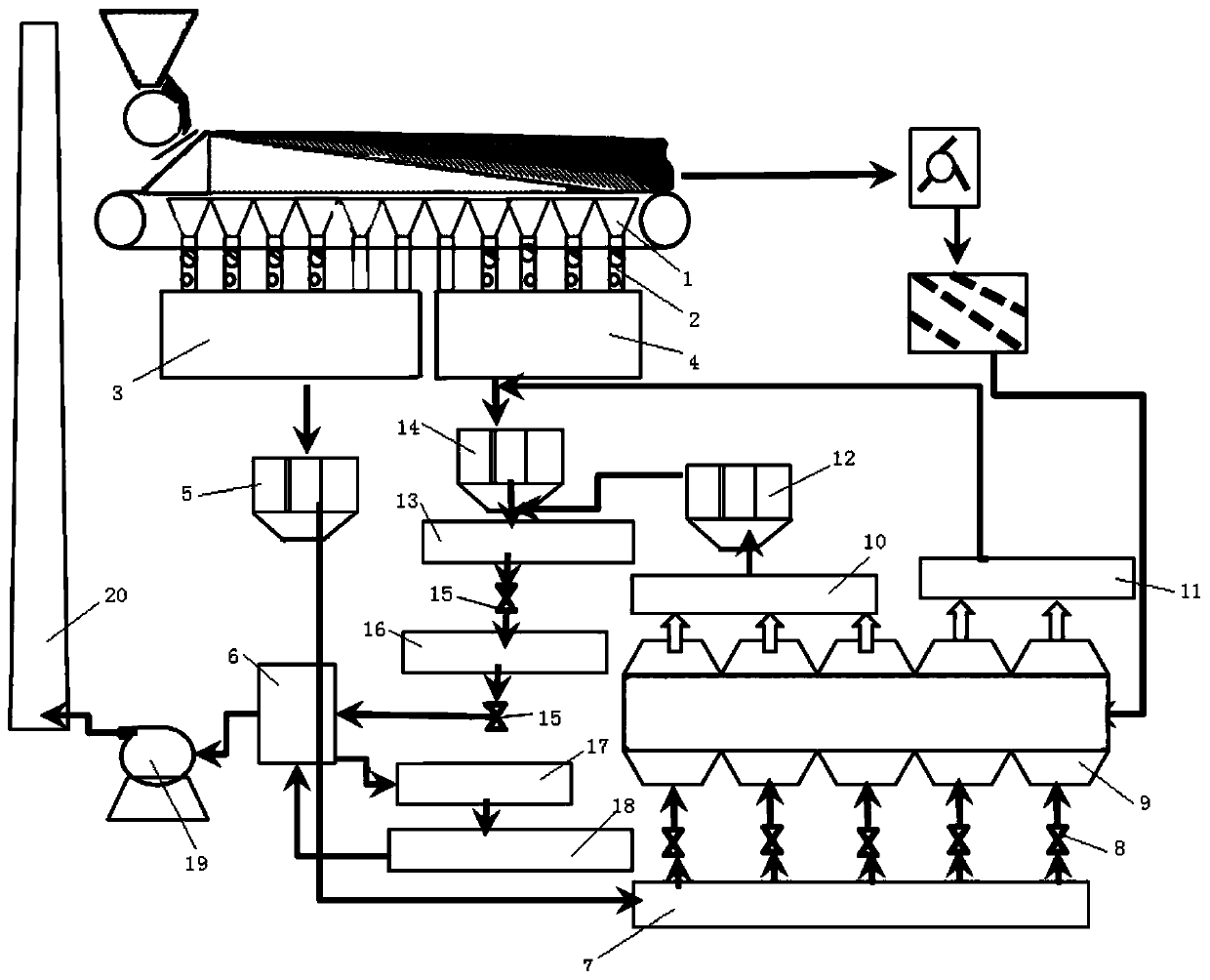

System for regulating and optimizing smoke by power generation and recycle of residual heat of sintering ring cold machine

ActiveCN101655319ATake advantage ofOptimize the operation modeEnergy industryIncreasing energy efficiencyIron plantEngineering

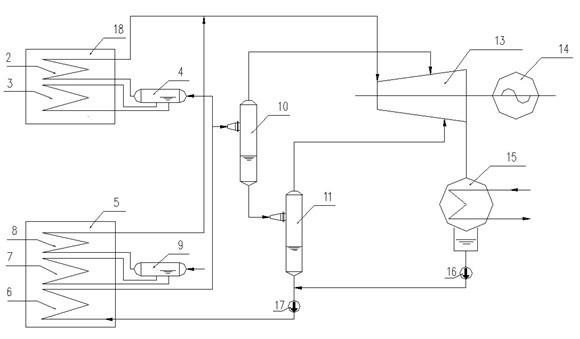

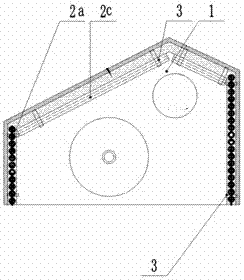

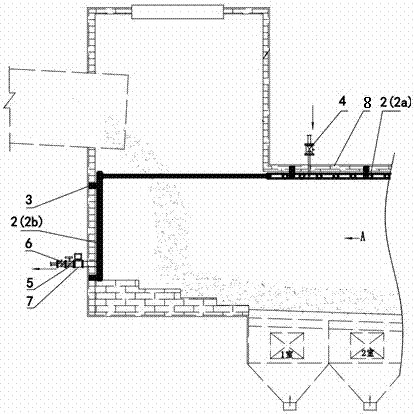

The invention discloses a system for regulating and optimizing smoke by power generation and recycle of residual heat of a sintering ring cold machine, which mainly comprises a ring cooling machine, a ring cooling machine wind box, a ring cooling machine wind chamber, a switching baffle door, a dual-pressure boiler without resisual heat and a steam filling and condensing type dual-pressure steam turbine, wherein the ring cooling machine wind chamber is divided into a high-temperature wind chamber and a low-temperature wind chamber which are respectively connected with the dual-pressure boilerwithout resisual heat through inlet flues, the steam outlet of the dual-pressure boiler without resisual heat is connected with the steam filling and condensing type dual-pressure steam turbine, and the outlet of a sediment chamber of the dual-pressure boiler without resisual heat is connected with a circulation fan through the flues and a wind complementing door. The invention has the highest efficiency in recovering residual heat, can use the resisual heat of sintering mineral materials at most, keeps stability, high efficiency and contineous operation for power generation by using the residual heat, and has important meaning for steal and iron plants.

Owner:ZHEJIANG XIZI UNITED ENG

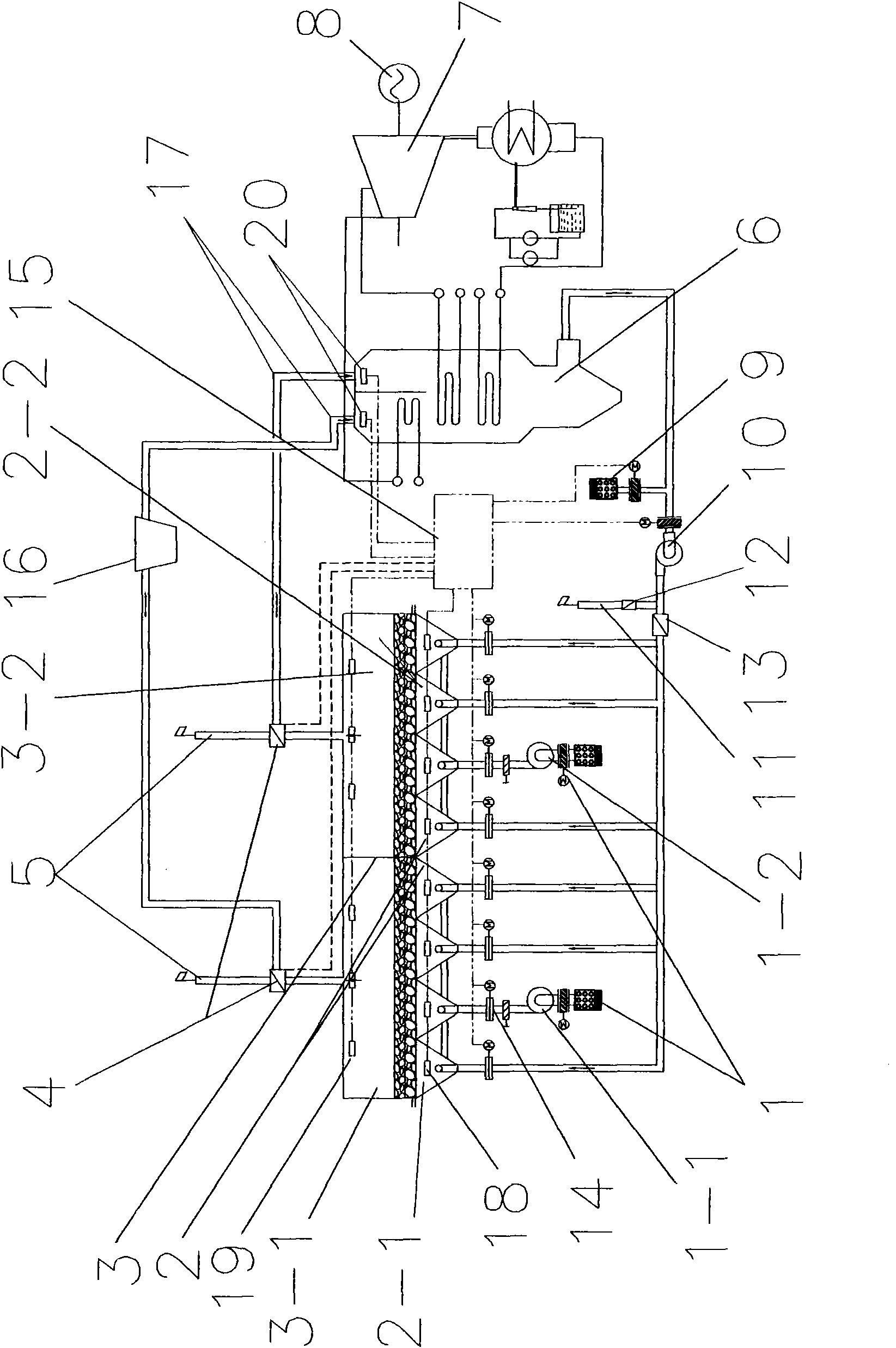

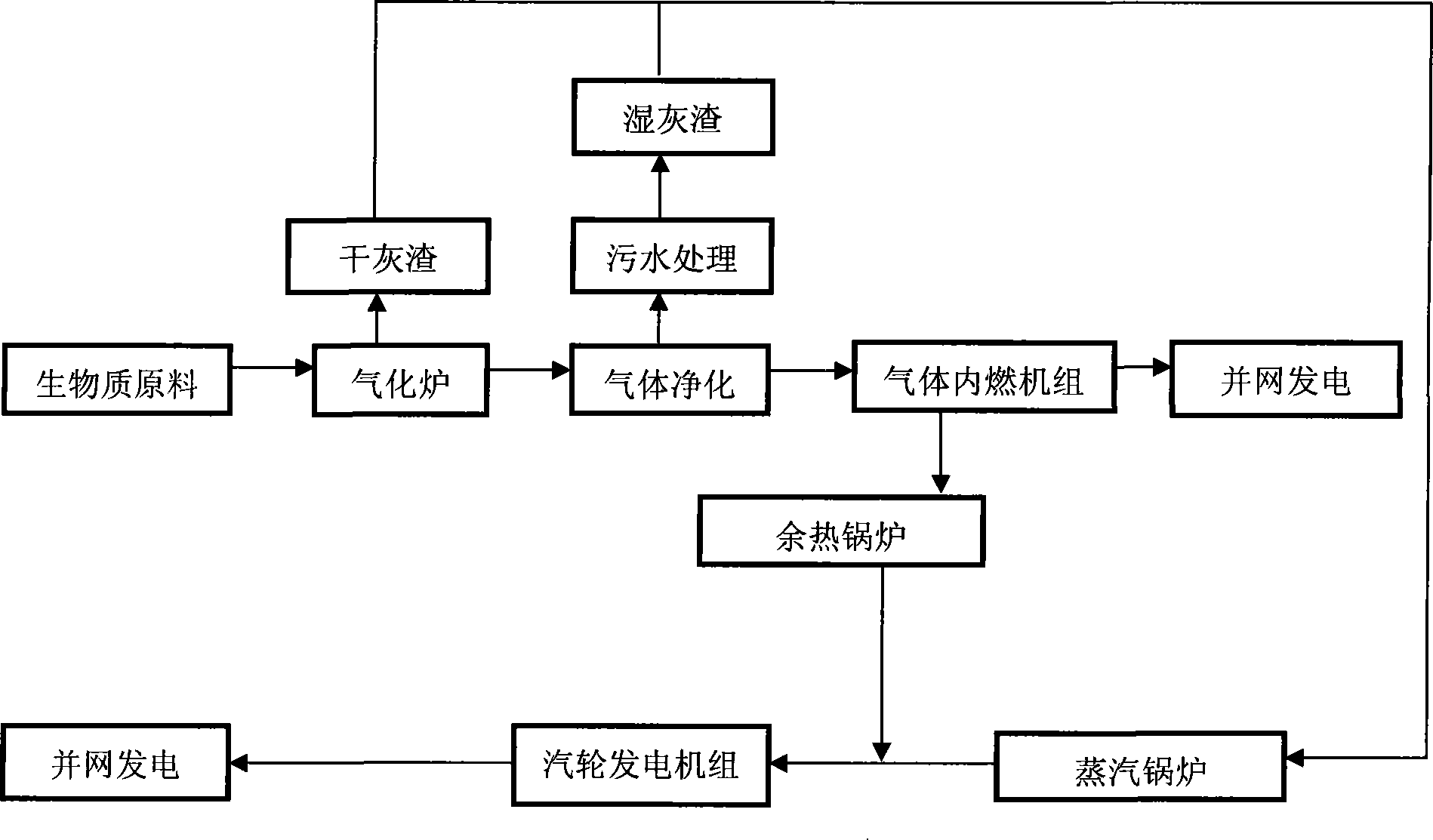

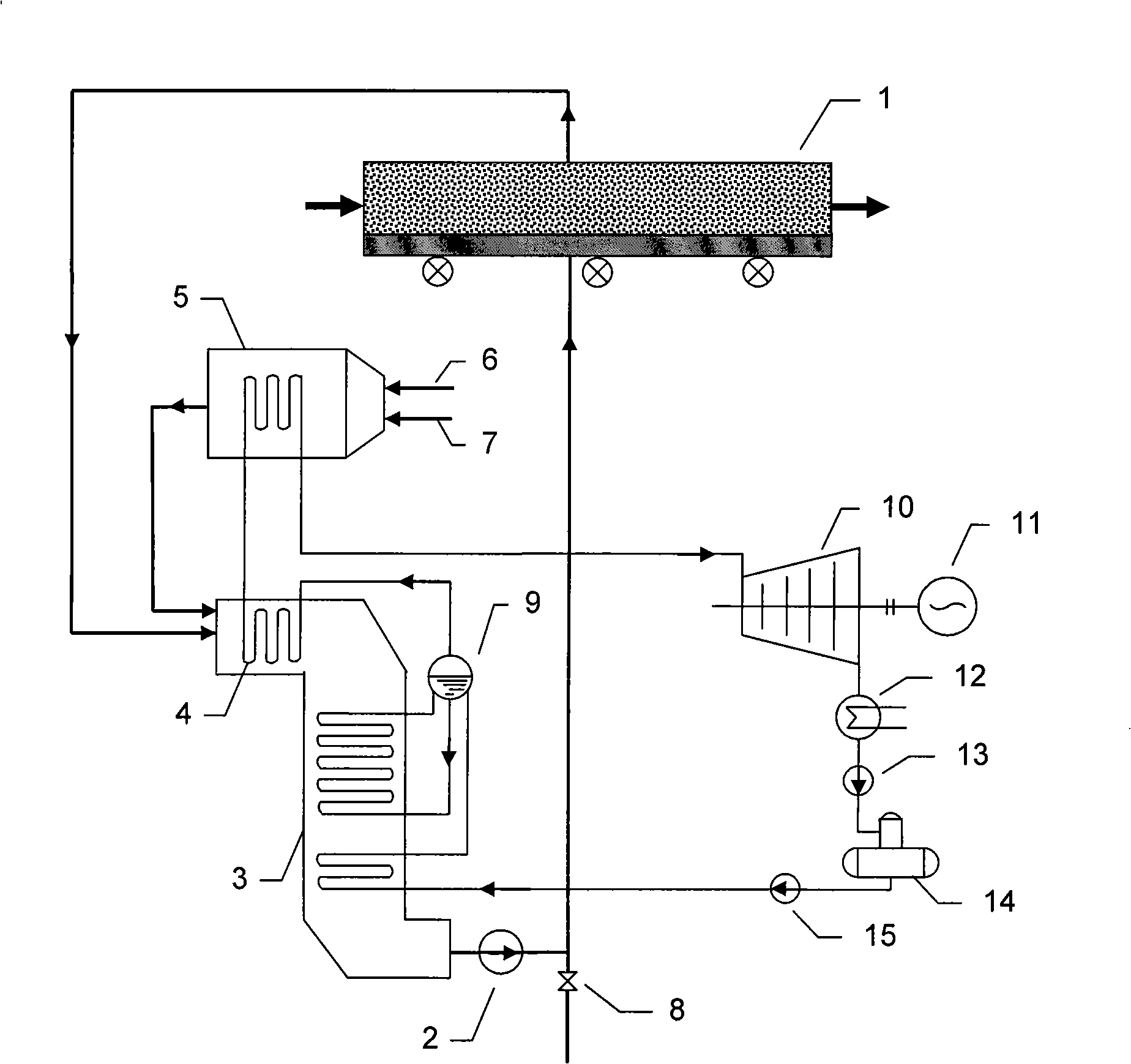

Biomass energy circulation electrification technique as well as generating system thereof

InactiveCN101251045ATake advantage ofImprove power generation efficiencyInternal combustion piston enginesFeed water supplyThermal energyInternal combustion engine

The invention provides a biomass energy IGCC technology which is characterized in that the technology comprises the following steps that: (1) the biomass raw material is gasified to be converted into the combustible gas which is dedusted and decoked as well as purified and is sent to a gas internal-combustion engine to generate electricity; (2) the biomass raw material or the clinker generated in the gasification and power generation process in the step 1 or the mixture of the two is sent to a steam boiler to be burnt in order to generate the superheated steam; the exhaust heat of the gas internal-combustion engine of the step 1 is inlet to an exhaust-heat boiler to generate the superheated steam; (3) the superheated steam generated by the steam boiler and the exhaust-heat boiler of the step 2 is sent to a turbonator set. The biomass energy IGCC technology takes full advantage of the heat energy and the product generated by each processing step in the biomass energy gasification and power generation process and generates electricity circularly, thereby greatly raising the power generation efficiency, taking full advantage of waste materials and lowering the running cost. The invention also discloses a power generation system for realizing the biomass energy IGCC technology.

Owner:黄家笙 +1

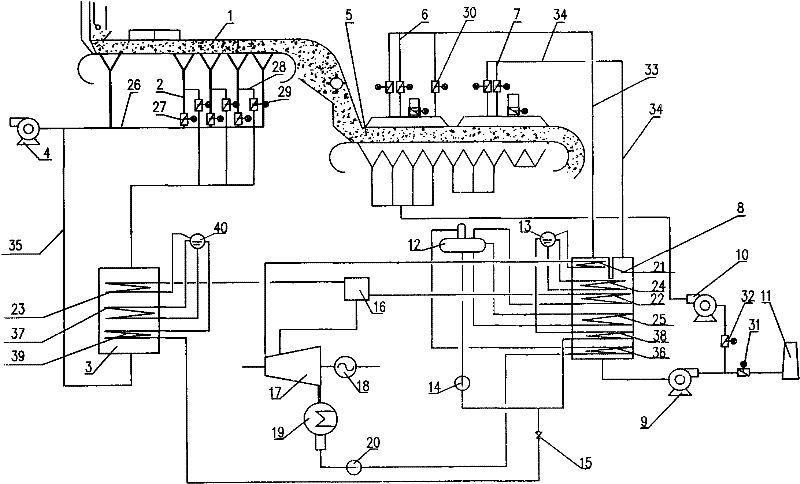

CO2 circulating and coal gas compensation combustion type power generation method by sintered waste heat

ActiveCN101344360AImprove waste heat power generation capacityIncrease waste heat power generationIncreasing energy efficiencyHandling discharged materialSuperheaterEngineering

A CO2 circulation and gas complementary combustion type sintering waste heat power generation method belongs to the sintering waste heat utilization field. The method is characterized in that, CO2 is used for replacing air to be used as a cooling medium of sinter, the specific heat of the CO2 is greater than the air, the CO2 can more efficiently recover sensible heat of the sinter, thereby improving the parameters of steam which is used for power generation and increasing the power generation amount; cooling air carries out closed circulating cooling of the sinter and absorbs the sensible heat of the sinter during passing by a sinter layer, the heat is released at a waste heat boiler, the heat is circulated to a circulating cooling machine for cooling the sinter after temperature decrease, the closed circulation can reduce heat loss due to radiation, recover the heat to the maximum extent and simultaneously reduce the leakage amount of the CO2; a gas complementary combustion type high temperature superheater is arranged behind a low temperature superheater, thereby being capable of stabilizing the parameters of the steam when the temperature of the sinter is fluctuated, and flue gas can also be used for supplementing the CO2 amount in the closed circulating cooling. The method has the advantages of improving the parameters of the steam, greatly improving the sintering waste heat power generation capacity and having environmental protection benefits.

Owner:SHOUGANG CORPORATION +1

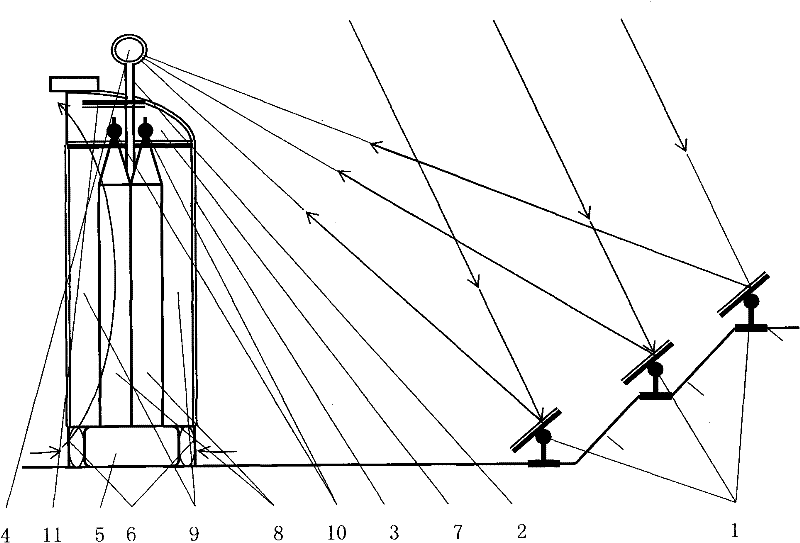

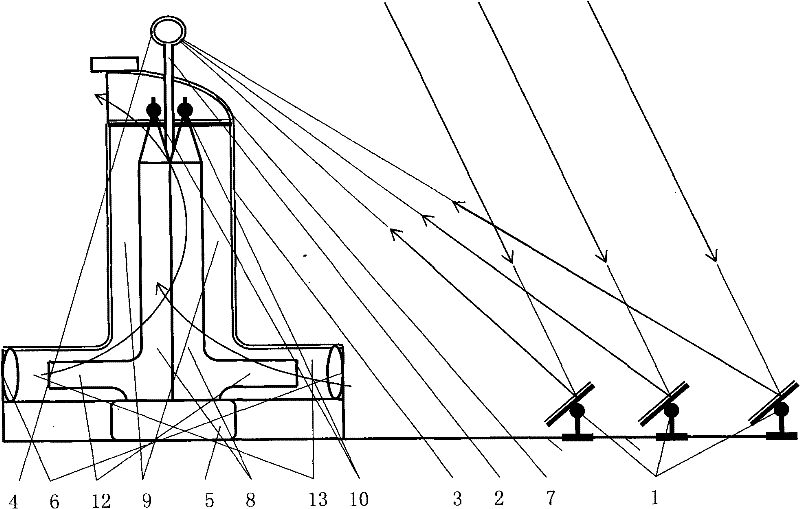

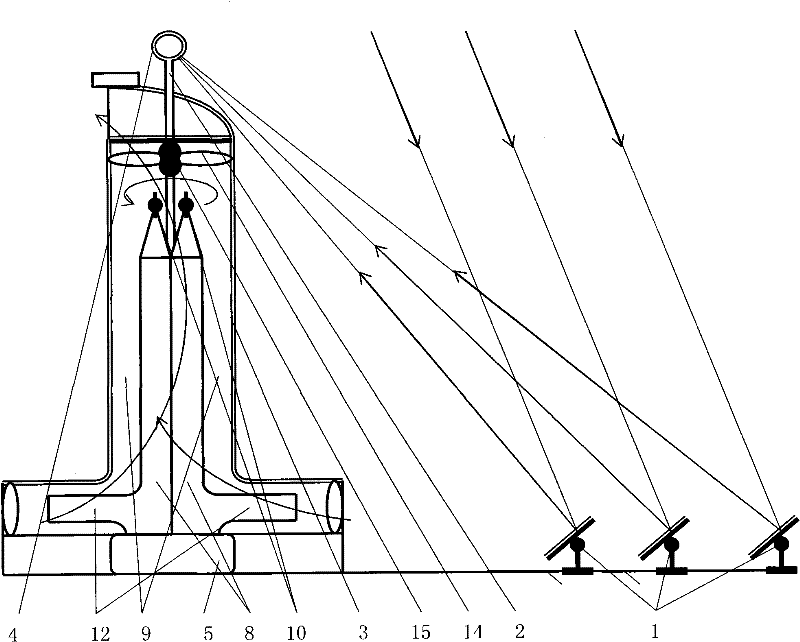

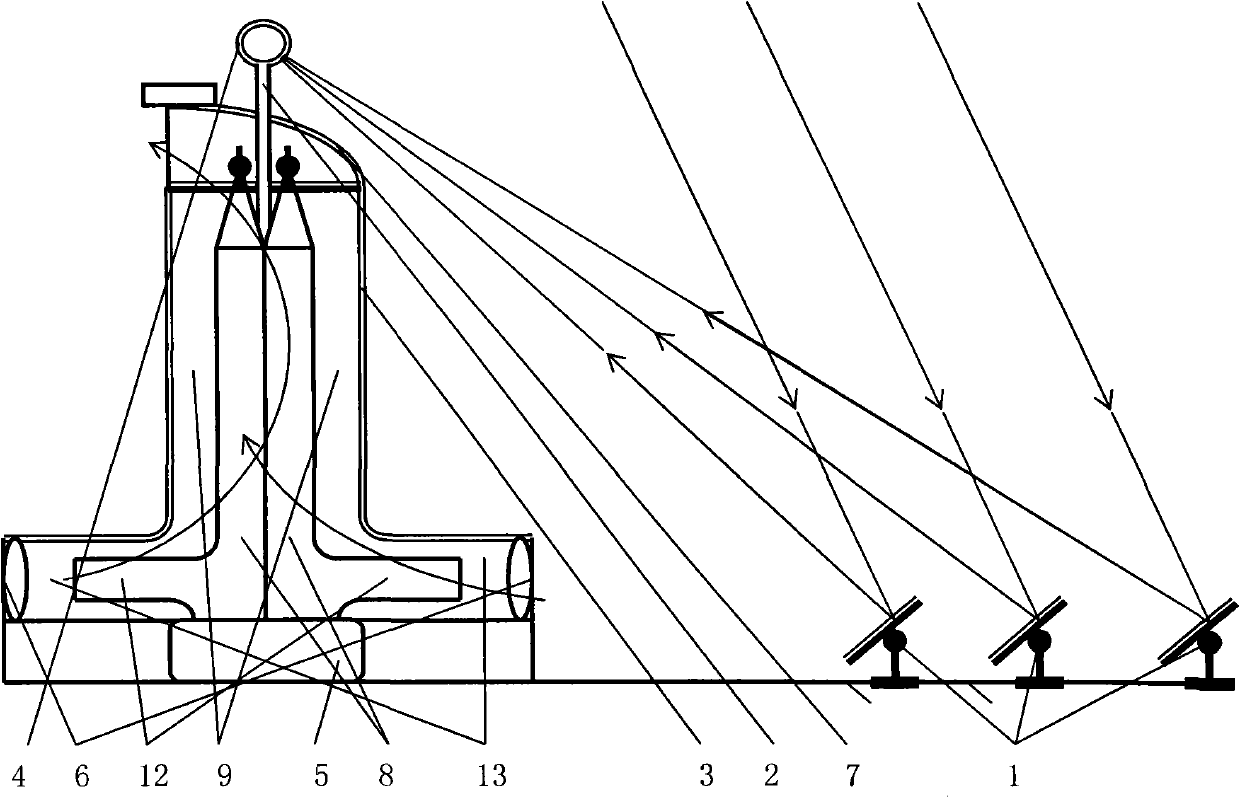

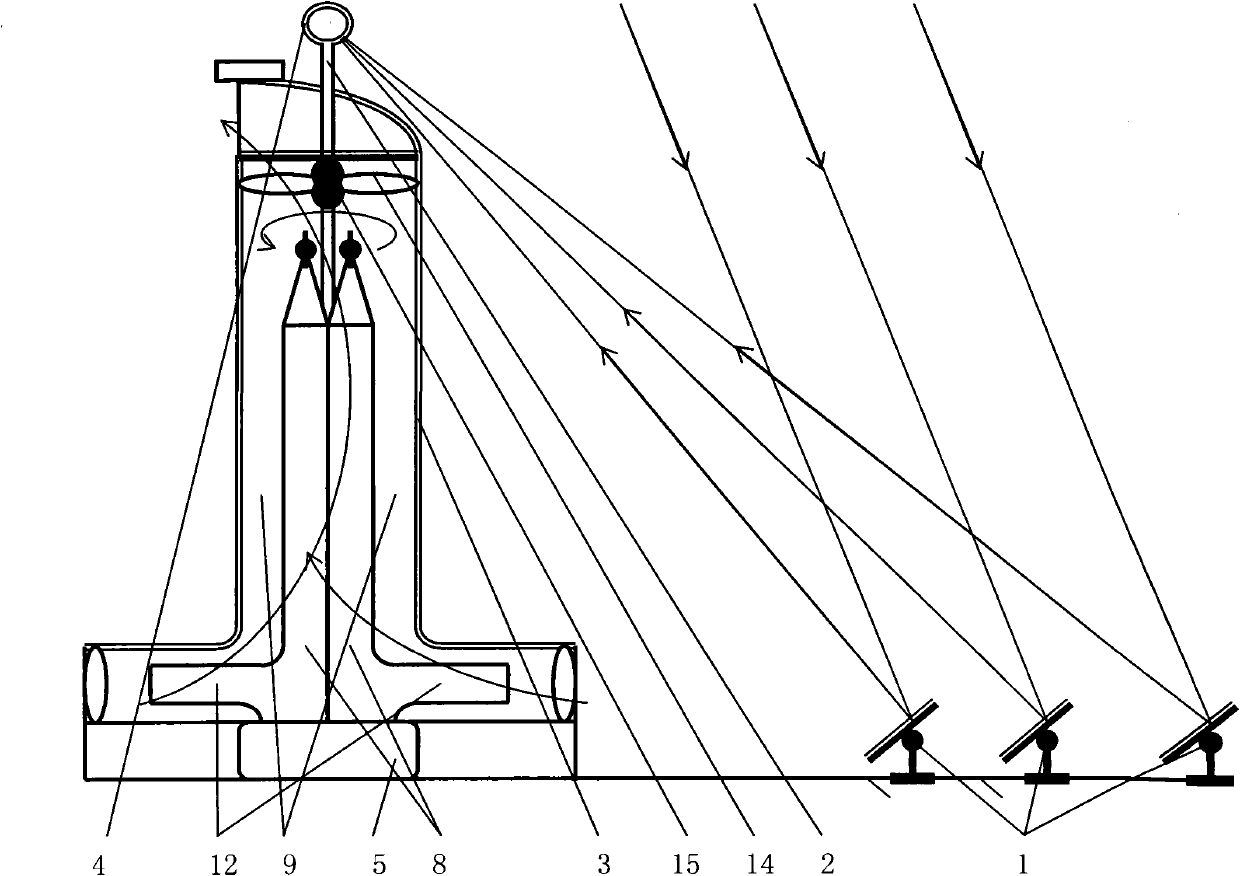

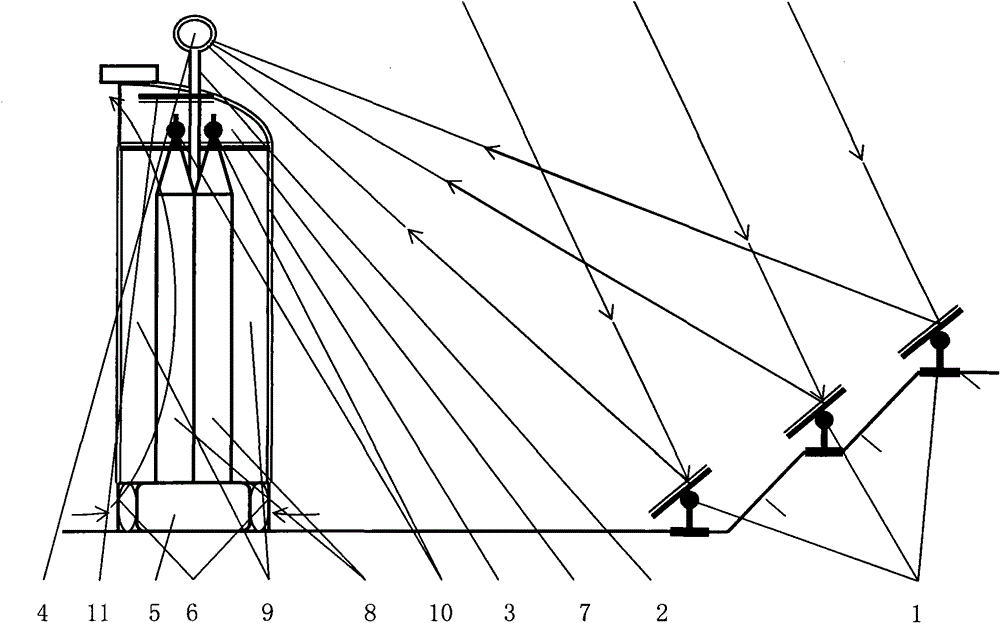

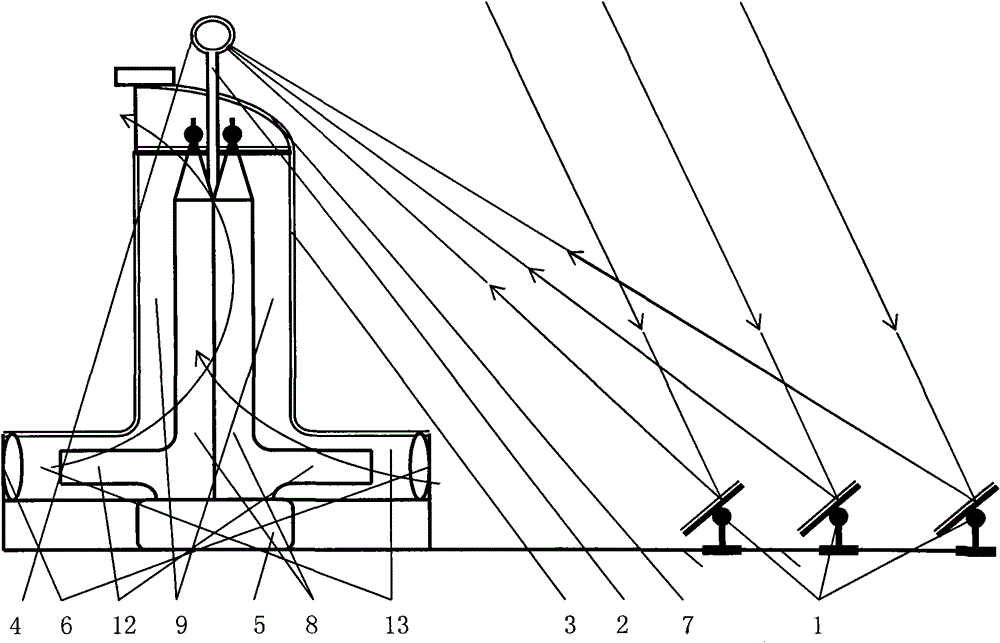

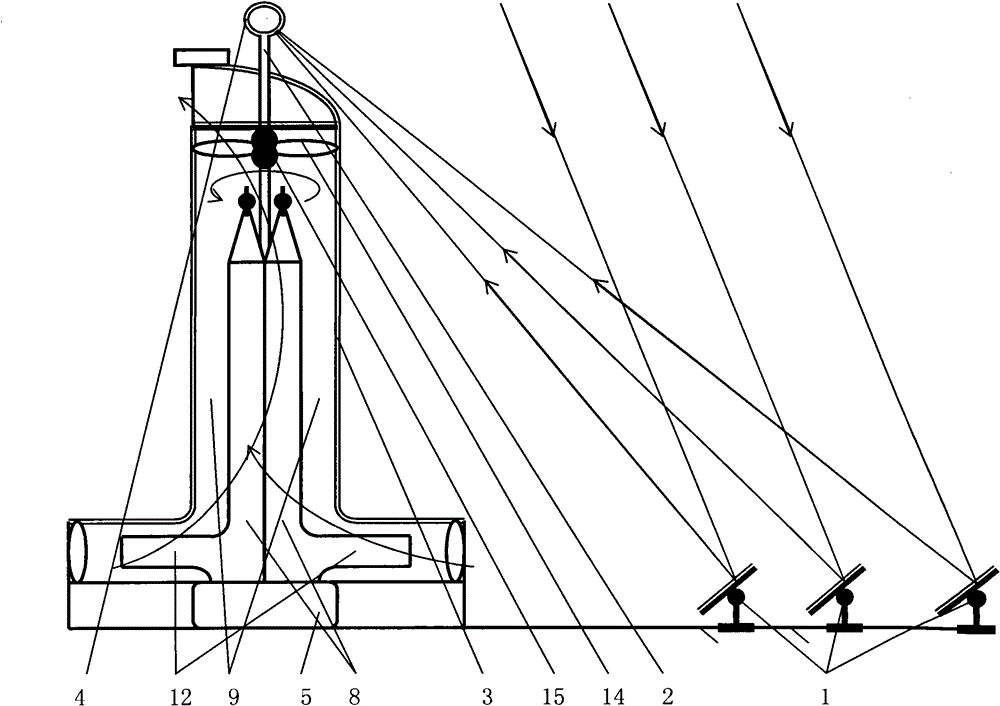

Siphon air-cooling tower-type solar thermal power generation device with exhaust valve

InactiveCN102536703AImprove reliabilityReduce usageSolar heating energySteam generation heating methodsSiphonExhaust valve

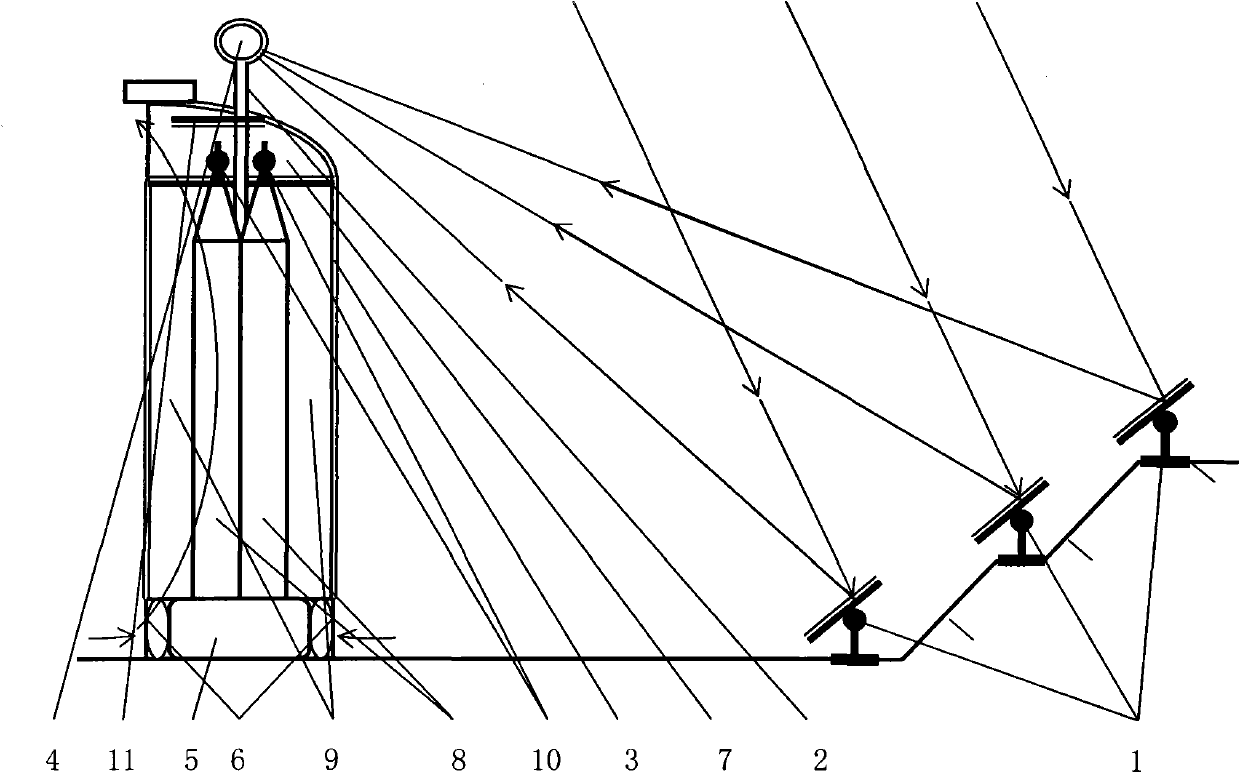

The invention provides a siphon air-cooling tower-type solar thermal power generation device with an exhaust valve. The siphon air-cooling tower-type solar thermal power generation device is composed of a reflecting mirror array, a vertical tower, a tower-top heat collector, a steam turbine and a cylindrical condenser, wherein the bottom and the upper end of the cylindrical condenser respectively comprise an air inlet channel and an air outlet channel; an exhaust-steam condenser is arranged in the cylindrical condenser; and the air inlet channel, the interior of the cylindrical condenser and the air outlet channel constitute an air channel. The siphon air-cooling tower-type solar thermal power generation device is characterized by comprising an automatic valve at the top end of the exhaust-steam condenser. The siphon air-cooling tower-type solar thermal power generation device has the beneficial effects that the air inlet channel, the interior of the cylindrical condenser and the air outlet channel constitute the air channel and a siphon effect is used to realize forced air cooling. Compared with water cooling, the forced air cooling has the advantages of no need of power and cooling water, greatly reduced investment and site selection conditions, capabilities of saving operation cost and high reliability. The automatic valve is arranged at the top end of the exhaust-steam condenser, and the outer end of the automatic valve is communicated with a negative pressure source so as to remove noncondensable gas in the steam turbine. Four embodiments are presented with combination of attached drawings.

Owner:施国庆

Two-stage flash evaporator of waste heat power generation system of cement kiln

InactiveCN103574571ASimple systemLow costSteam generationIncreasing energy efficiencyEvaporatorFlue gas

The invention relates to a two-stage flash evaporator of a waste heat power generation system of a cement kiln The waste gas utilization efficiency of the cement kiln can be particularly improved during waste heat power generation by the aid of the two-stage flash evaporator. The two-stage flash evaporator is characterized in that two flash evaporators are serially connected with each other, a coal economizer is connected with a water inlet of the primary flash evaporator by a pipeline, a water outlet of the primary flash evaporator is connected with a water inlet of the secondary flash economizer, a water outlet of the secondary flash evaporator is connected to a boiler feed water pump, and a steam outlet of the primary flash evaporator and a steam outlet of the secondary flash evaporator are respectively communicated with a rear stage of a steam turbine to do work. The two-stage flash evaporator has the advantages that a system is simple and is low in cost, convenient to operate and adaptive to the characteristic of sharp fluctuation of waste gas parameters of the cement kiln, maximum generated power can be acquired from low-grade heat sources, the exhaust temperature of a boiler can be about 90 DEG C under the control, the heat utilization rate of low-temperature flue gas can be increased, and accordingly the purpose of utilizing energy to the greatest extent can be achieved.

Owner:娄卡奔新能源科技发展(上海)有限公司

Two-stage flash evaporator capable of improving waste steam utilization efficiency for waste heat generation in cement kiln

InactiveCN102537921AIncrease waste heat power generationImprove reliabilitySteam generationIncreasing energy efficiencyEngineeringCement kiln

The invention relates to a two-stage flash evaporator for a waste heat generating system in a cement kiln, particularly to a two-stage flash evaporator capable of improving the waste steam utilization efficiency for the waste heat generation in a cement kiln. Two flash evaporators in cascade connection; a coal economizer is connected with the water inlet of the first-stage flash evaporator through a pipeline; the water outlet of the first-stage flash evaporator is connected with the water inlet of the second-stage flash evaporator; the water outlet of the second-stage flash evaporator is connected with a boiler feedwater pump; and the steam outlets of the first-stage and the second-stage flash evaporators are communicated with the rear stage of the turbine for acting. The two-stage flash evaporator is characterized in that the two-stage flash evaporator has simple structure and low cost, is convenient to operate, is suitable for the large-amplitude fluctuation of the waste heat parameters in the cement kiln, can enable the low-grade heat source to obtain the maximum generation power, can control the exhaust temperature of the boiler to the range about 90 DEG C, improves the heat utilization rate of the low-temperature smoke, and achieves the purpose of utilizing the energy to the maximum degree.

Owner:娄卡奔新能源科技发展(上海)有限公司

Siphon air cooling method for tower-type solar heat power generation device and equipment

InactiveCN102562502AImprove reliabilityReduce usageFrom solar energySteam engine plantsSiphonEngineering

The invention discloses a siphon air cooling method for a tower-type solar heat power generation device. A cylindrical condenser is used in the method, and the bottom and the upper end of the cylindrical condenser are respectively provided with an air inlet passage and an air outlet passage; the air inlet passage, the inner part of the cylindrical condenser and the air outlet passage form an air flue; and an exhaust steam condenser in the air flue is cooled by using the heat siphon effect. The tower-type solar heat power generation device manufactured by the method consists of a reflector array, a vertical tower, a tower top heat collector, a steam turbine and the cylindrical condenser. The device is characterized in that: the bottom of the cylindrical condenser is provided with the air inlet passage, and the upper end of the cylindrical condenser is provided with the air outlet passage; and the exhaust steam condenser of the solar heat power generation device is arranged in the cylindrical condenser. The air inlet passage, the inner part of the cylindrical condenser and the air outlet passage form the air flue with low air resistance. The invention has the advantages that: power is not required in heat siphon air cooling, cooling water is not required, the construction land can be reduced, the investment is reduced, the operating cost and the internal power utilization are reduced, and the reliability is improved. Four embodiments are shown in attached figures.

Owner:XUZHOU FENGTONG INFORMATION TECH CO LTD

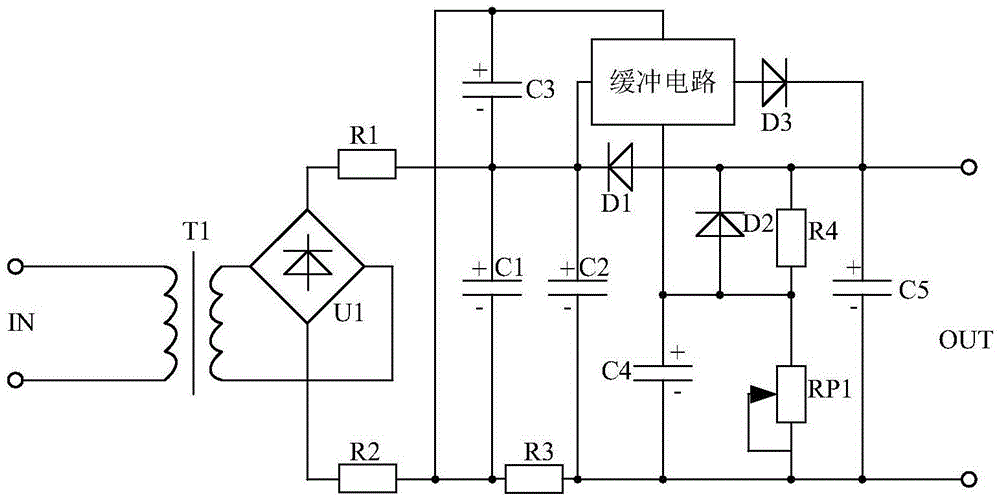

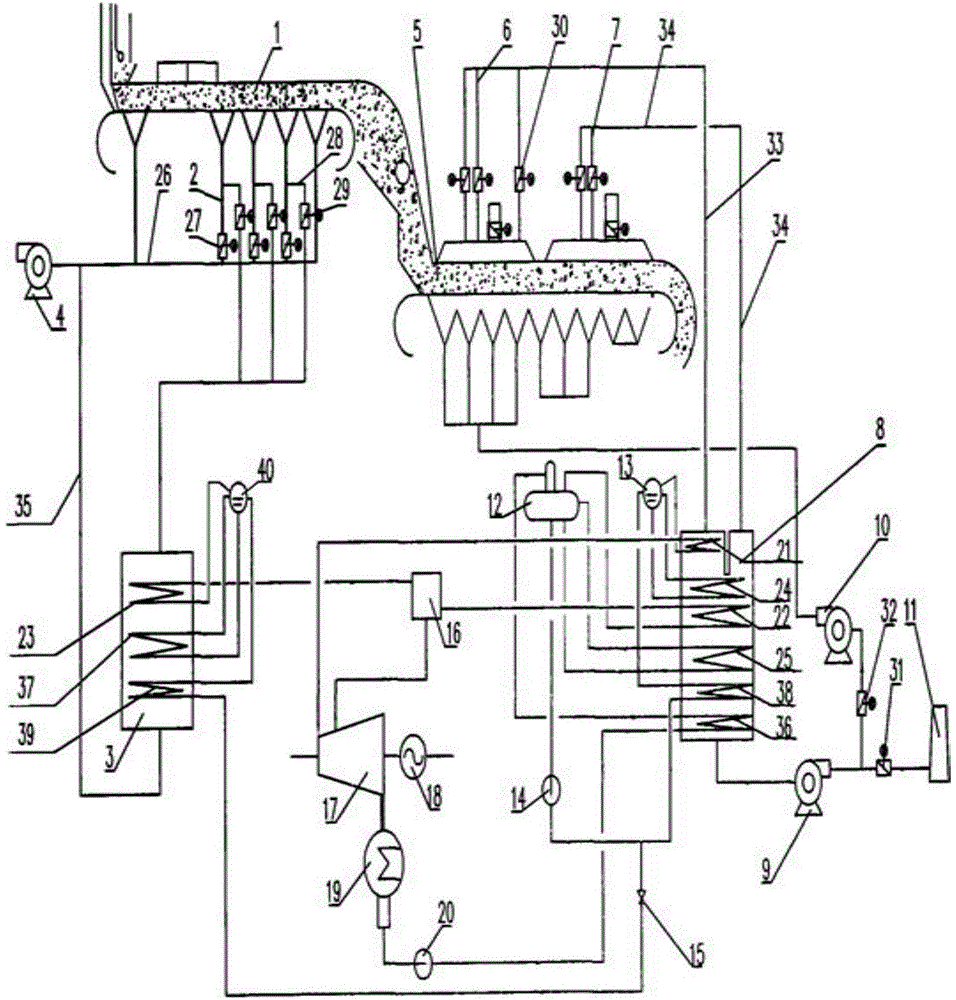

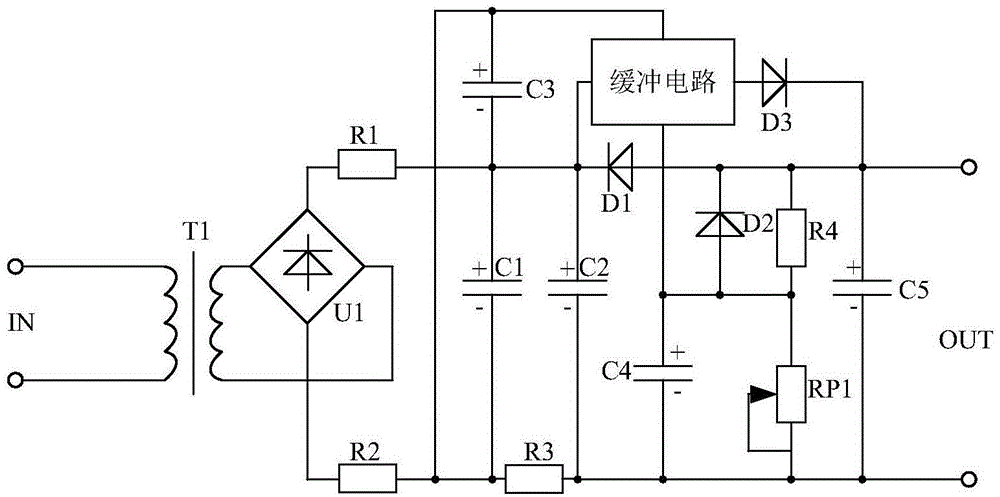

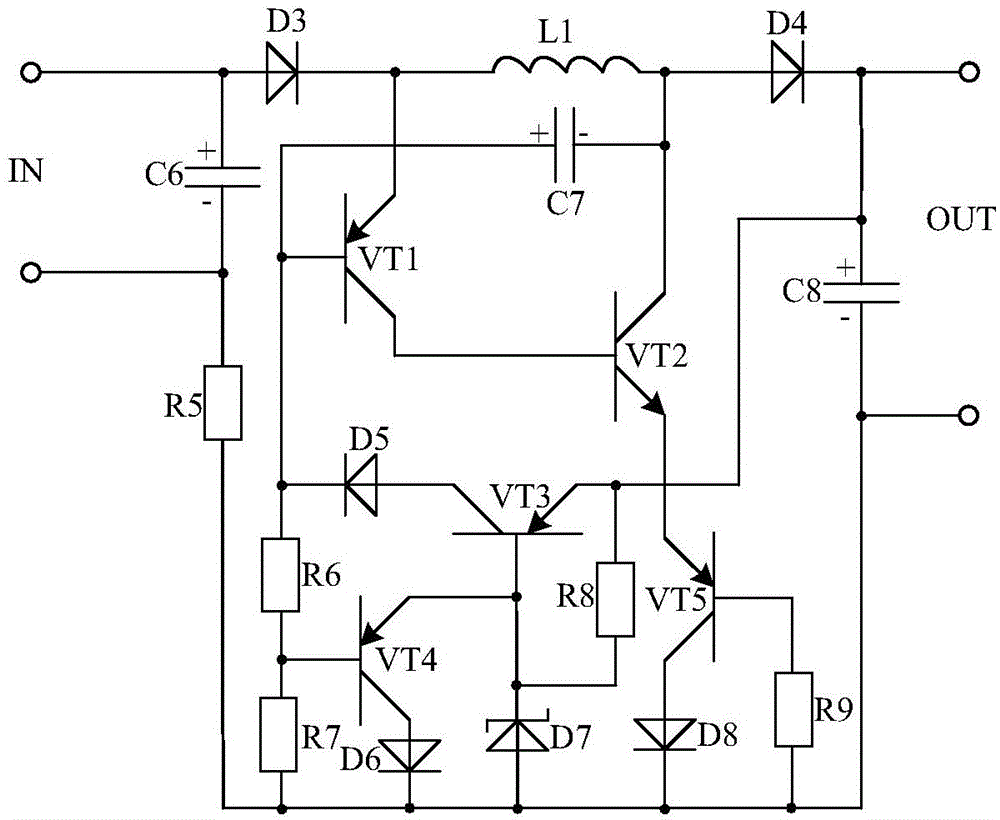

Sintering waste heat power generation system based on buffering power circuit

InactiveCN104880084AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencyMachines/enginesEngineeringTurbine

The invention discloses a sintering waste heat power generation system based on a buffering power circuit. The sintering waste heat power generation system comprises a sintering machine hot smoke system, a hot waste gas waste heat utilizing system and a sintering waste heat power generation thermodynamic system. A buffering power source output system connected to the output end of a turbine generator is arranged in the sintering waste heat power generation thermodynamic system and comprises the buffering power circuit and a storage battery or a power utilization device connected with the buffering power circuit. The buffering power circuit is composed of a buffering circuit and a power circuit. The stability of products is improved, the service life of the products is prolonged, the increasing and improving of a running circuit in the products are carried out, and storage battery or power utilization device damage caused by overhigh voltage fluctuation is avoided.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Cement kiln head waste heat power generation method and system

ActiveCN104949534BImprove efficiencyReasonable useIncreasing energy efficiencyWaste heat treatmentEngineeringSuperheater

The invention relates to a cement kiln head waste heat power generation method and system. The waste heat power generation system comprises a grate cooler, a kiln head AQC furnace, a high temperature superheater boiler and a connecting air hose, wherein a high temperature extract opening and a medium temperature extract opening which are connected with a high temperature air hose and a medium temperature air hose are formed in the grate cooler, the kiln head AQC furnace is communicated with the medium temperature air hose through pipelines, a high temperature superheater boiler air inlet and a high temperature superheater boiler air outlet are formed in the high temperature superheater boiler, the high temperature superheater boiler air inlet is connected with the high temperature air hose through a pipeline, the high temperature superheater boiler air outlet is communicated with the kiln head AQC furnace through a pipeline, one end of the connecting air hose is communicated with the high temperature air hose, and the other end of the connecting air hose is communicated with the medium temperature air hose. According to the method and system, the connecting air hose is arranged between the high temperature air hose and the medium temperature air hose, the sufficient and surplus air temperature in the high temperature section is led to the medium temperature section for use, the design technology that the high temperature and the medium temperature are used separately is broken, utilization of a heat source is more reasonable, and the work efficiency of the kiln head AQC furnace is greatly improved.

Owner:CHINA RESOURCES CEMENT TECH RES DEV

System and method for using sintering waste heat to generate electricity

InactiveCN101806230BImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityProcess engineering

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of thering cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

Method for improving cement production waste heat power generation capacity

InactiveCN104457289AHigh calorific valueImprove circulation rateIncreasing energy efficiencyHandling discharged materialImpellerMaterials science

The invention discloses a method for improving cement production waste heat power generation capacity and belongs to the technical field of cement production waste heat power generation. The method comprises the following steps that (a) a certain amount of gangue is added to cement raw materials, and the heating capacity of the cement raw materials is improved; (b) the diameter of an impeller of a clinker cooling draught fan is increased by 5% to 10% under the condition that the width is not changed, and a motor of the cooling draught fan is not changed; (c) a water preheating pipeline is additionally arranged at a waste gas outlet of a preheater, and the water preheating pipeline is communicated with a water feeding channel of a power generating boiler. By the adoption of the method, the cement production waste heat power generation capacity can be increased by 8% to 10%, and the comprehensive benefits of cement production can be effectively increased.

Owner:ANYANG XINTIANHE CEMENT

Cement clinker shock cooling process adopting material layer self-protection technology

InactiveCN112611230AGuaranteed cooling effectImprove clinker qualityHandling discharged materialAir volumeClinker (waste)

The invention discloses a cement clinker shock cooling process adopting a material layer self-protection technology. An original third-generation grate cooler shell is dismounted and overall replaced with a LANE type tail-mounted rolling fourth-generation grate cooler; all fans are newly purchased, a waste heat power generation air pipe and a coal mill air pipe are installed between a settling chamber above the grate cooler and a mill air inlet, and an auxiliary air pipe is additionally arranged on a waste air pipeline. The cement clinker shock cooling process has the advantages that a large-area fixed grate bed, a thick material layer and an air volume adjusting valve are arranged, clinker shock cooling is truly achieved, and the clinker quality is improved while the cooling effect is guaranteed; the heat efficiency is improved by 2%, and the corresponding coal consumption is greatly reduced; the heat recovery effect is improved, and the middle air temperature is greatly increased.

Owner:铜川声威建材有限责任公司

Electricity generating method for increasing cement production waste heat

InactiveCN105417973AReasonable useImprove waste heat utilizationClinker productionSteam generation using hot heat carriersSuperheaterHigh pressure

The invention discloses an electricity generating method for increasing cement production waste heat and relates to the technical field of cement production. The method comprises the following steps that 1, a heat conduction fin is installed on the inner wall of a cement cellar, and the heat conduction fin is connected with a steam water tank; 2, carbonaceous mudstone particles are added to a cement raw material, and heat generated by the carbonaceous mudstone particles in the material compounding process and heat of the cement raw material are transmitted to the steam water tank through the heat conduction fin; 3, a steam superheater is installed on an air hose of the cement cellar, heat is collected by the steam superheater in the process that the air hose of the cement cellar conducts heat dissipation, and the heat is transmitted to a steam turbine generator unit through a heat high pressure machine. By means of the electricity generating method, the waste heat can be utilized reasonably for generating electricity, the waste heat utilization rate is high, energy is saved, heat generated in the production process can be increased, and waste heat electricity generating capacity is effectively raised.

Owner:WUXI JIANGDA ENERGY SAVING TECH CO LTD

Production equipment and preparation method of nano environment-friendly fire coal combustion-supporting sulfur-fixing agent

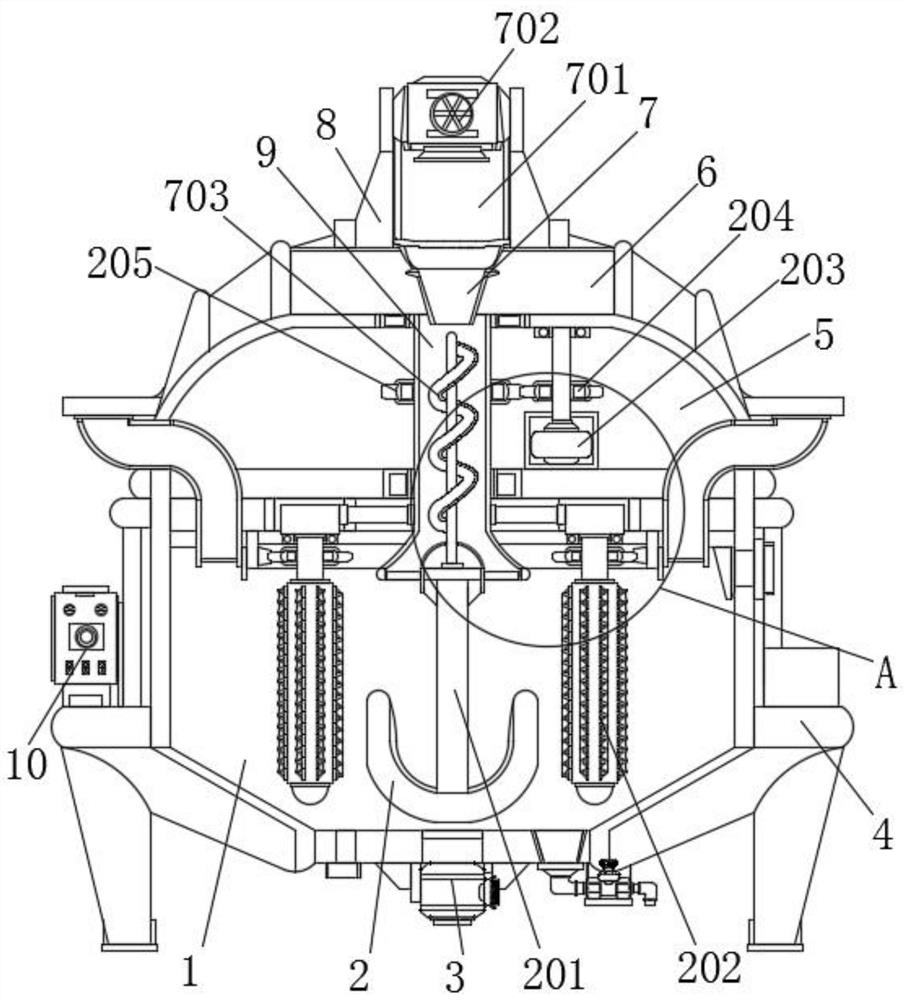

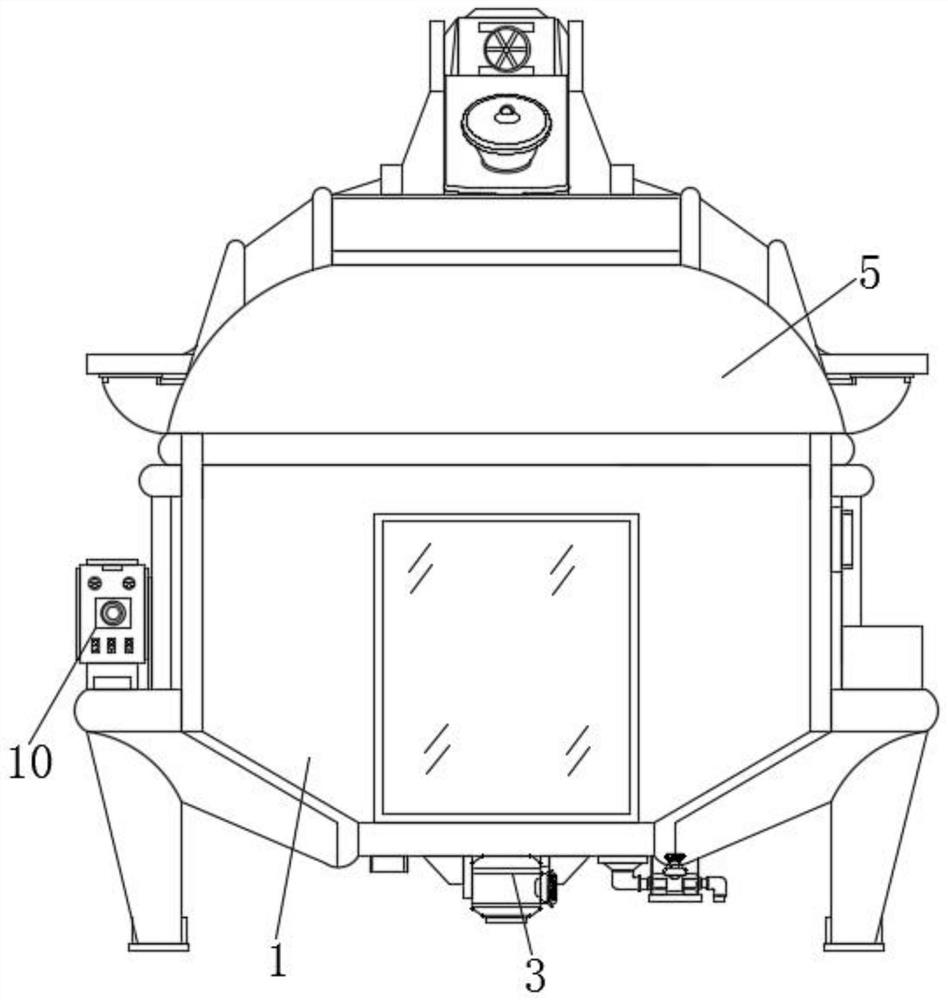

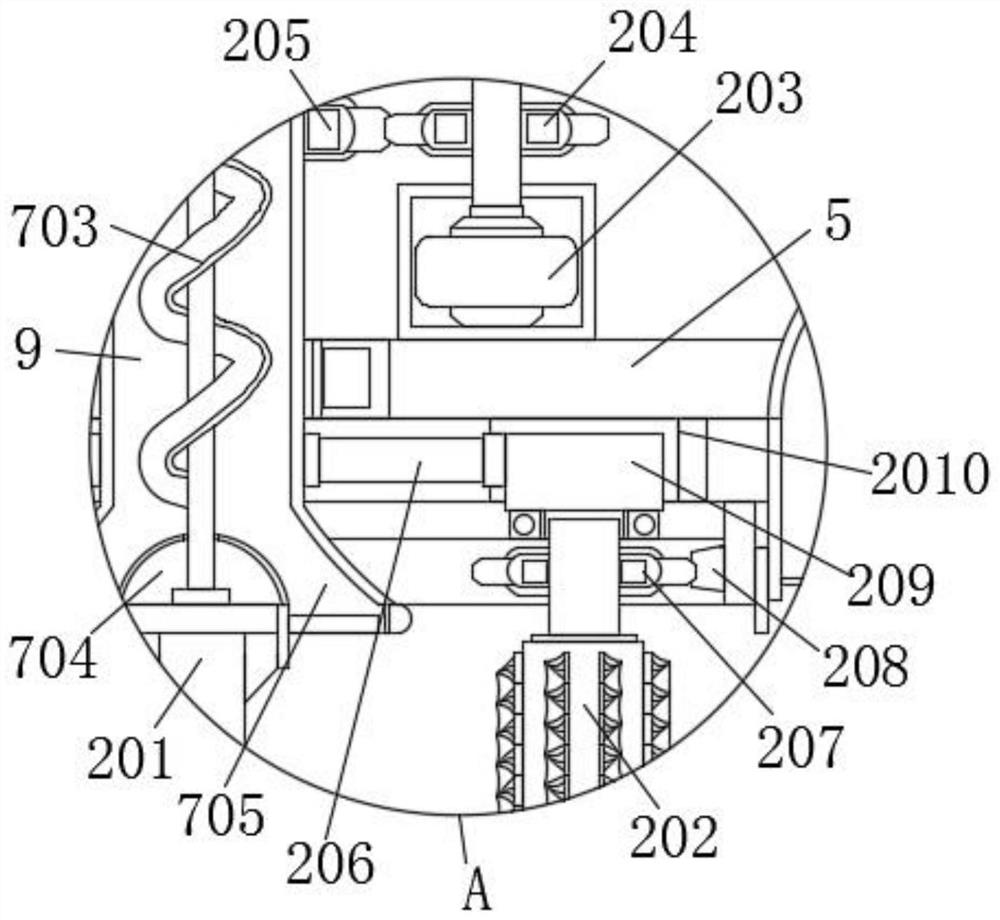

ActiveCN113234515AHigh thermal efficiencyPromote combustionProcess control/regulationSolid fuelsCombustionExhaust fumes

The invention discloses a production equipment and preparation method of a nano environment-friendly fire coal combustion-supporting sulfur-fixing agent. The production equipment comprises a reaction kettle body, a top groove is formed in the top of the reaction kettle body, a mounting groove is formed in the top of the top groove, connecting frames are arranged on the two sides of the top of the mounting groove, a powder flow guide assembly is arranged in the middle of the interior of the mounting groove, and fixing seats are arranged at the bottoms of the two sides of the reaction kettle body. The combustion-supporting sulfur-fixing agent for the fire coal can improve the combustion condition of a furnace body, enhance the air permeability of a coal seam, enable the coal to be fully combusted, improve the heat efficiency of the fire coal, reduce the emission of smoke dust, improve the heat conduction efficiency, fix sulfur, reduce smoke, reduce the emission of CO and SO2 and reduce environmental pollution, so that the purposes of supporting combustion, fixing sulfur, saving energy and desulfurizing are achieved; and the coal saving rate of a cement kiln or a boiler can reach 10% or above, the yield of the cement kiln is increased by 5% or above, the firepower is increased by 10% or above, NOx, dust and the like in waste gas can be effectively reduced, and the waste heat generating capacity of the cement kiln can be increased by 2 kWh / t or above.

Owner:青海新雨田化工有限公司

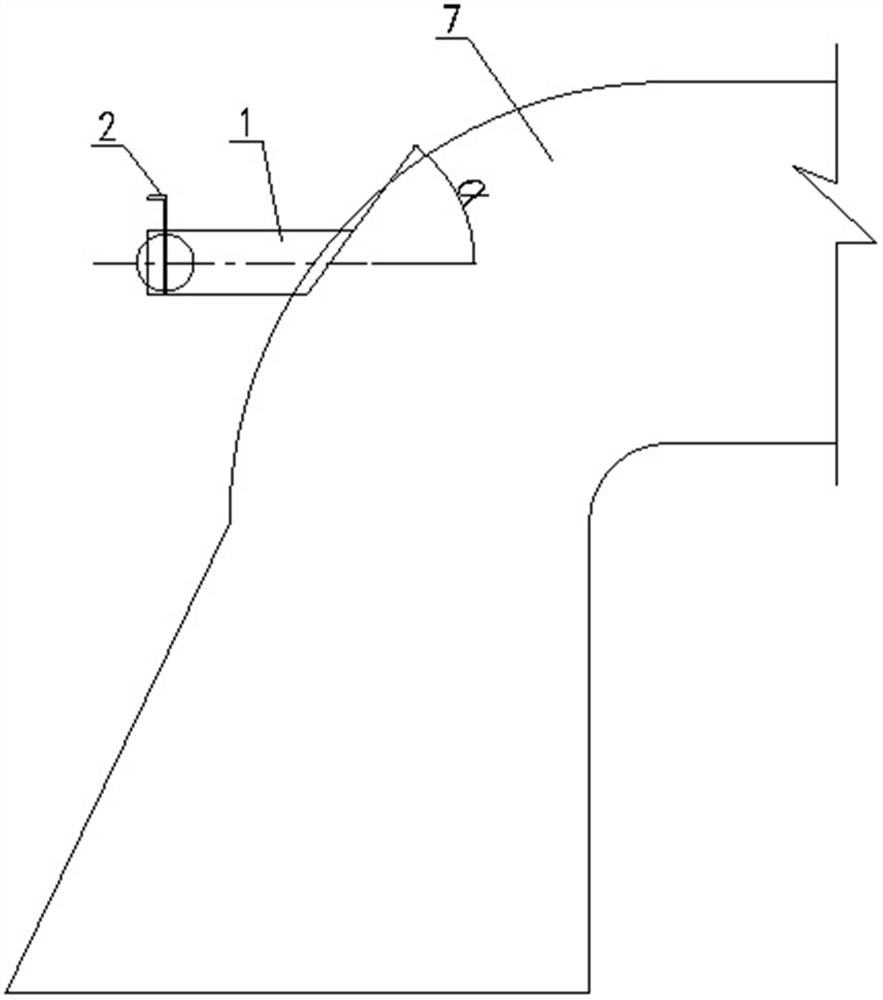

Tertiary air inlet for heat recovery coke oven

PendingCN113322081AIncrease temperatureEasy to burnCombustible gas coke oven heatingCoke oven detailsThermodynamicsCoke oven

The invention belongs to the technical field of heat recovery coke ovens in the metallurgical industry, and particularly relates to a tertiary air inlet for a heat recovery coke oven, wherein the tertiary air inlet is characterized in that the tertiary air inlet is arranged on the pipe wall of an ascending pipe and comprises an air inlet pipe and a valve component, an included angle of 45-60 degrees is formed between the axis direction of the air inlet pipe and the pipe wall, and the inner end of the air inlet pipe is flush with the inner side of the pipe wall of the ascending pipe or continues to stretch into the ascending pipe by 10-50 mm; and the ratio of the diameter of the air inlet pipe to the diameter of the ascending pipe mounting section is 1:(3-8). Compared with the prior art, the tertiary air inlet has the beneficial effects that the problems that the generation amount of coal gas is greatly changed along with volatile components, coking time and the like of mixed coal in the heat recovery coke oven production in the current metallurgical industry, the air introduction amount of the primary and secondary air inlets of the coke oven cannot be accurately matched with raw coke oven gas, so that combustible components still escape along with a gas collection system, and the environment is polluted are solved.

Owner:辽宁科技大学工程技术有限公司

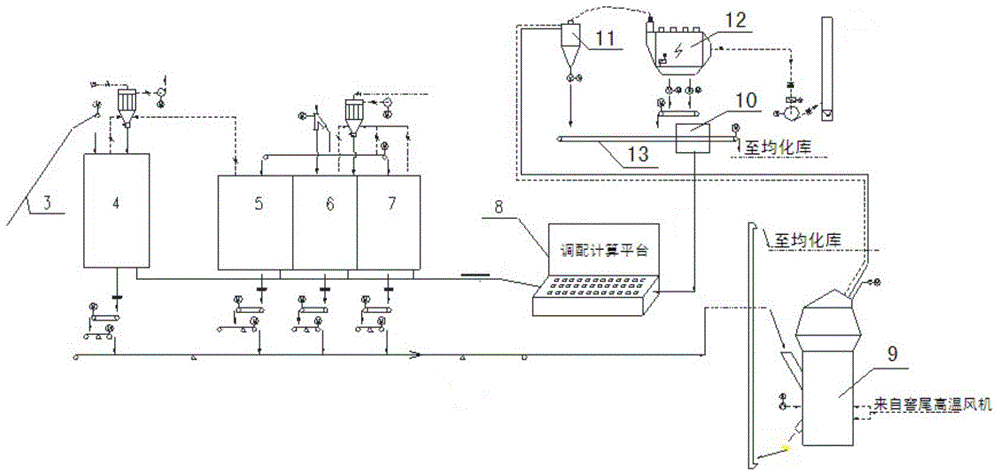

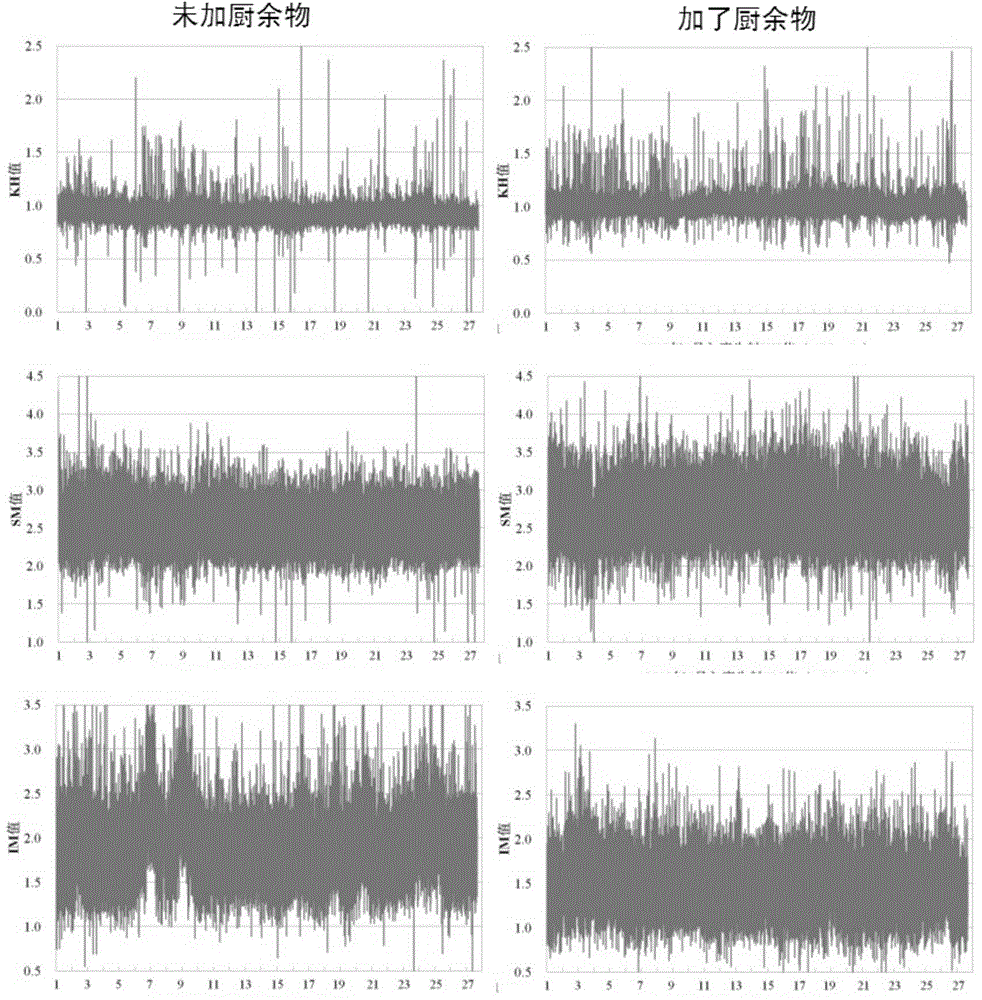

A method for improving the grindability of cement raw meal and reducing toc emission by using kitchen waste

ActiveCN103936310BImprove grindabilityReduce power consumptionClinker productionCombustionChemical composition

The invention discloses a method used for improving cement raw material grindability and reducing TOC discharge with kitchen waste. According to the method, the kitchen waste collected from municipal solid waste is mixed with raw materials which are used for preparing cement raw material; and an obtained mixture is delivered into a flour mill for grinding, wherein the outlet of the flour mill is provided with a gamma-Metric analyzer used for real-time monitoring on chemical components of the discharged cement raw material. According to the method, kitchen waste is added into a raw material grinding system so as to improve grindability of the cement raw material, and reduce power consumption of the flour mill; ash obtained via combustion of the kitchen waste can be used for replacing clay raw material; TOC discharge of a cement production system is reduced at the same time; a large amount of organic substances with relatively heat value are obtained via drying of the kitchen waste, and are burnt in a preheater so as to generate heat energy, so that the temperature of waste gas is increased, and waste heat power generation is increased; the kitchen waste is subjected to low-temperature drying grinding, a large amount of residual heat energy obtained via cerement plant waste heat power generation is recycled, a kitchen waste dewatering problem is solved, and processing cost of the kitchen waste is reduced.

Owner:SINOMA INT ENG

CO2 circulating and coal gas compensation combustion type power generation method by sintered waste heat

ActiveCN101344360BImprove waste heat power generation capacityIncrease waste heat power generationIncreasing energy efficiencyHandling discharged materialSuperheaterEngineering

Owner:SHOUGANG CORPORATION +1

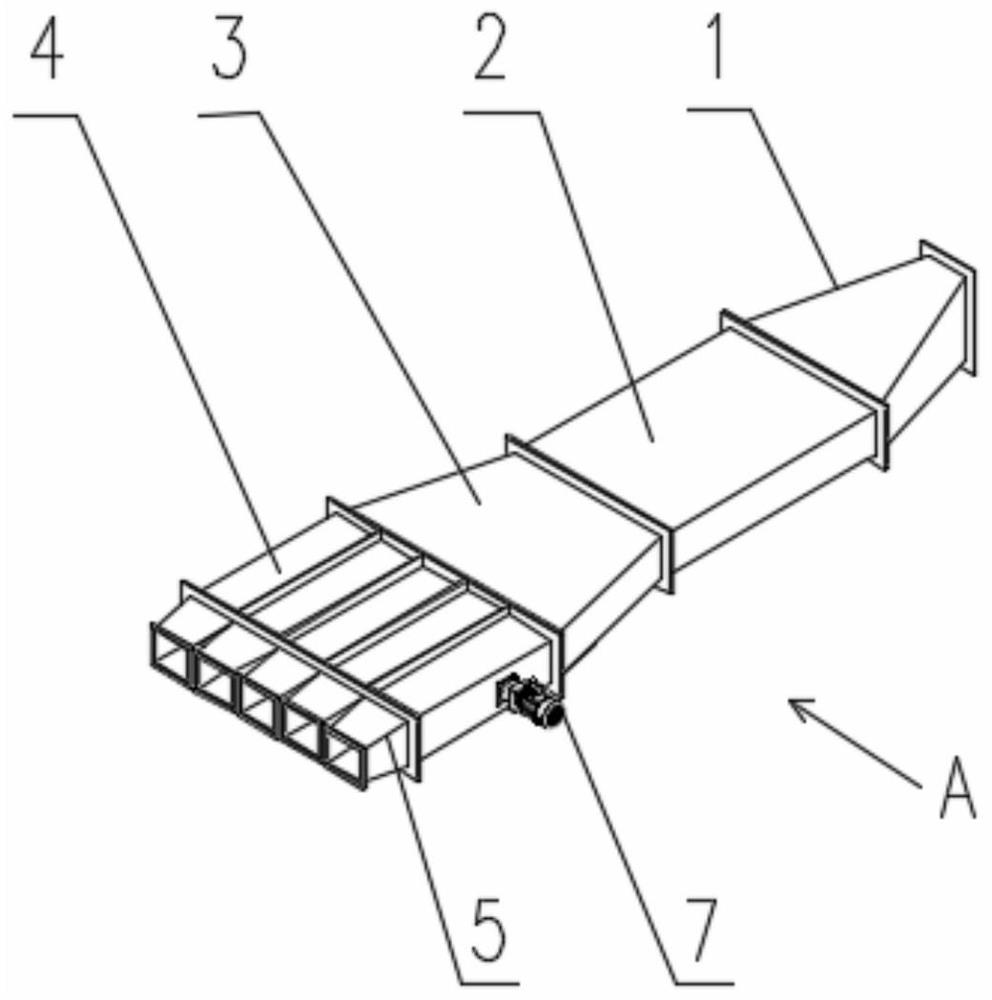

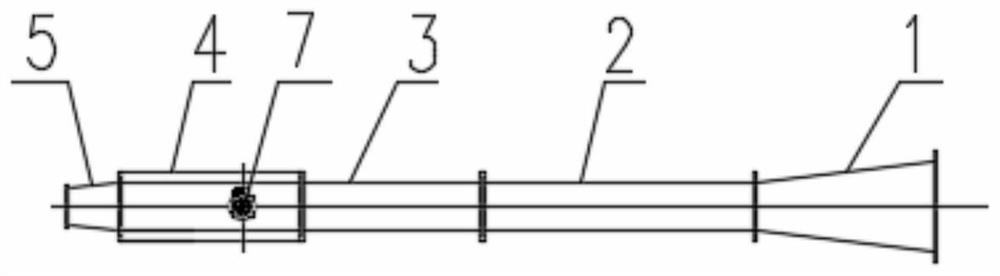

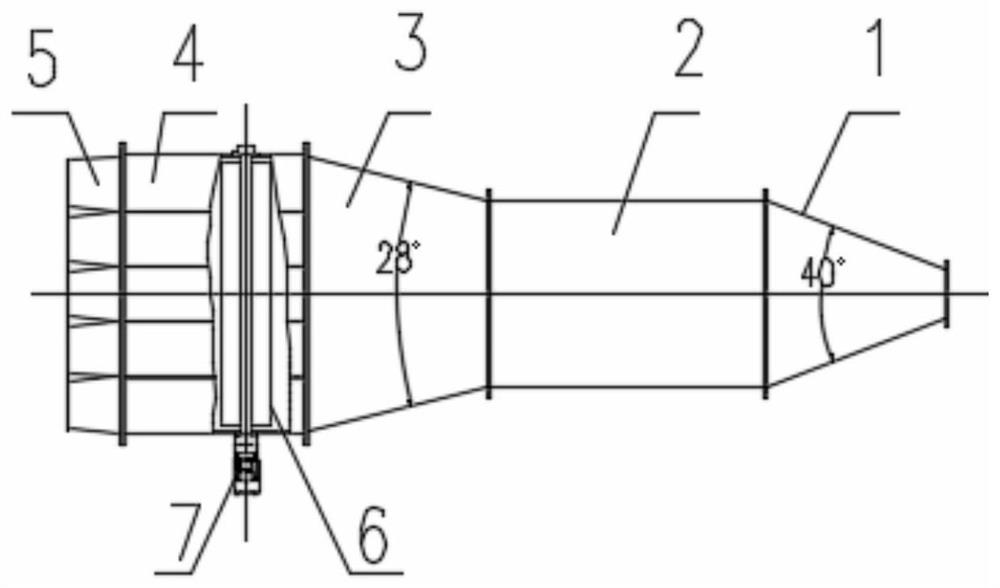

Pressure-stabilizing and air-controlling device for inflatable beam of grate cooler

PendingCN112129113AImprove cooling effectUniform air volume and air pressureHandling discharged materialWaste heat treatmentImpellerElectric machine

The invention discloses a pressure-stabilizing and air-controlling device for an inflatable beam of a grate cooler. The pressure-stabilizing and air-controlling device comprises a first mute diffuserpipe, a flow stabilizing pipe, a second mute diffuser pipe, a rectifying and pressure-stabilizing pipe and pressure dividing pipes; the first mute diffuser pipe and the second mute diffuser pipe are both of a V-shaped body structure; the large end of the first mute diffuser pipe is connected with the small end of the second mute diffuser pipe through the flow stabilizing pipe; the large end of thesecond mute diffuser pipe is connected with the at least two pressure dividing pipes; a rectifying and pressure-stabilizing impeller is arranged in the rectifying and pressure-stabilizing pipe; a main shaft is fixedly installed in the middle of the rectifying and pressure-stabilizing impeller and rotationally installed in the rectifying and pressure-stabilizing pipe; a driving motor and a speed reducer are fixedly installed at the outer side of the rectifying and pressure-stabilizing pipe; an output shaft of the driving motor is connected with an input shaft of the speed reducer; and an output shaft of the speed reducer is fixedly connected with the main shaft. The pressure-stabilizing and air-controlling device is simple in structure and easy to machine and manufacture, and the air pressure of air blown out of the pressure dividing pipes is uniform and stable.

Owner:重庆沃亚机械有限公司

Method for controlling ultralow emission of sintering flue gas

PendingCN111442652ALow costIncrease waste heat power generationCombination devicesGas treatmentMetallurgyFlue gas

The invention discloses a method for controlling ultralow emission of sintering flue gas. The method is characterized by comprising steps as follows: low-temperature sintering flue gas in a large coldair flue is introduced into a sintering ore cooling system, the temperature of the sintering flue gas is increased through sintering ore sensible heat, then the heated flue gas is introduced into a waste heat power generation system, and the flue gas obtained after power generation is subjected to desulfurization and denitrification and then is discharged out of a chimney through a main exhaust fan. According to the method for controlling ultralow emission of the sintering flue gas, the cost of a sintering flue gas emission reduction system can be reduced, the waste heat power generation capacity of the sintering machine is increased, and good application prospects are achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

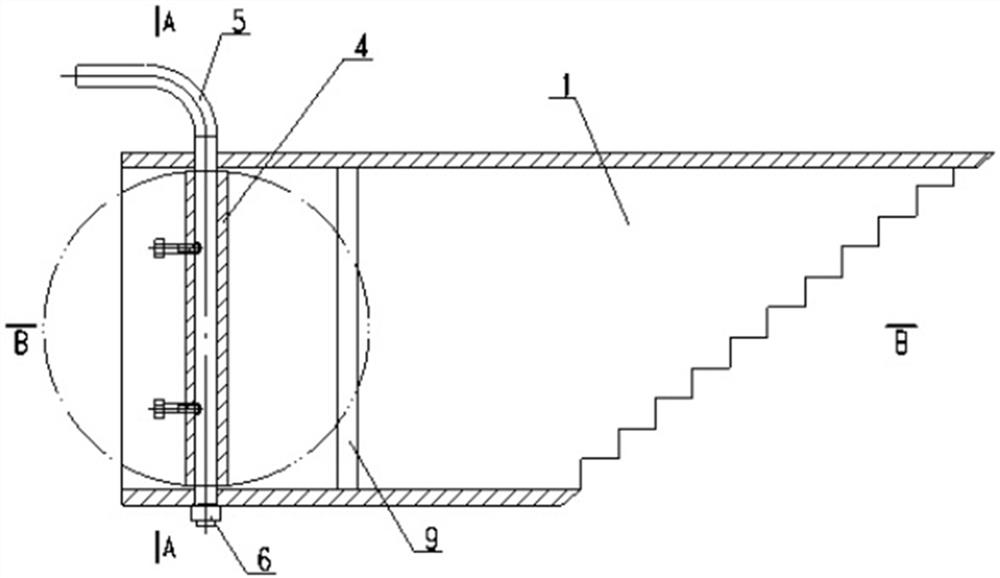

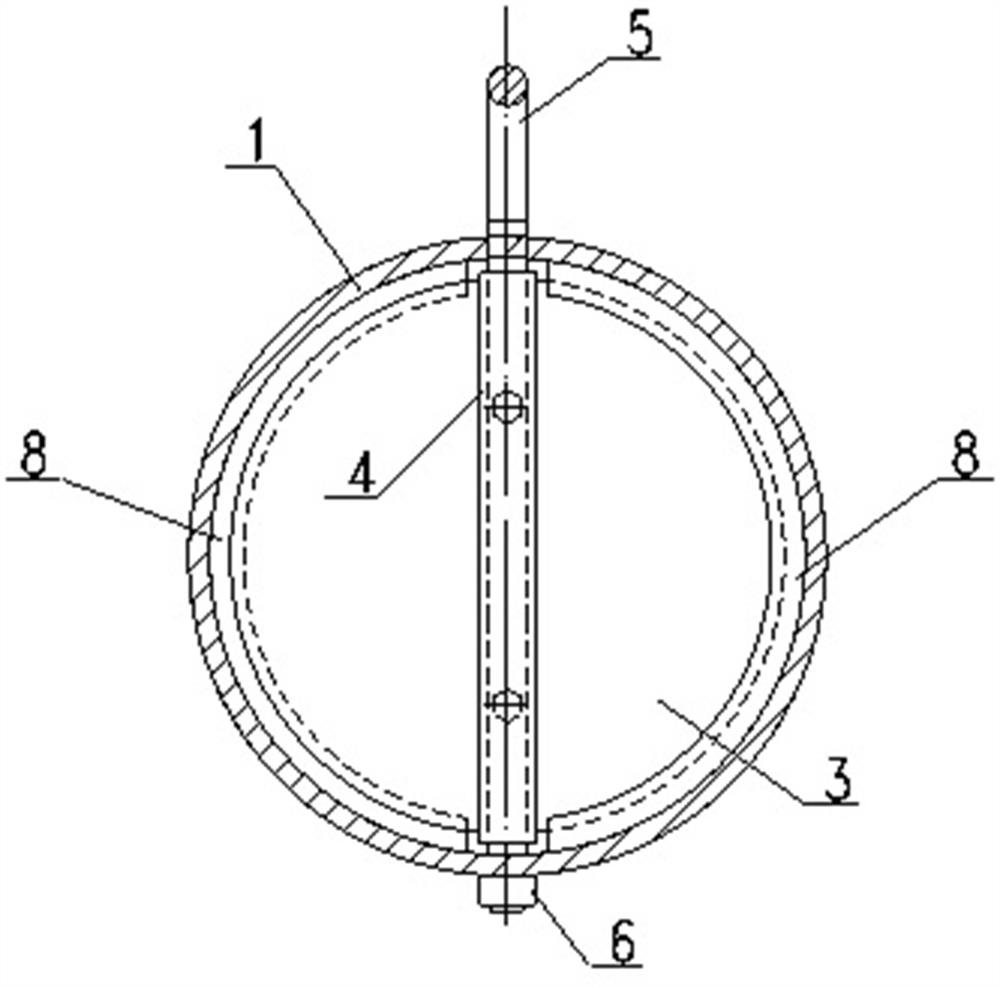

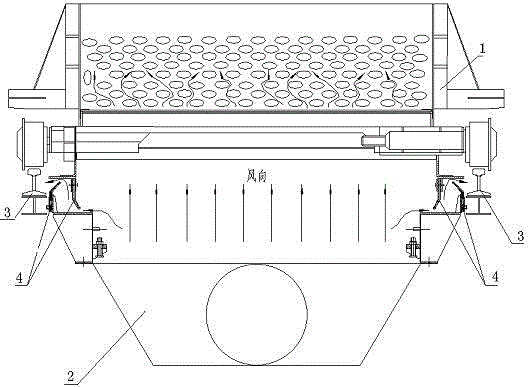

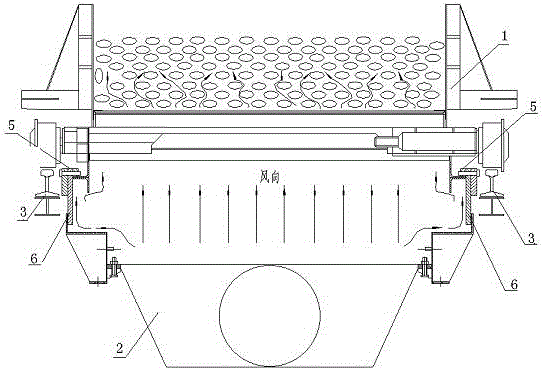

A dynamic sealing device for a sintering ring cooler

ActiveCN102937186BNot easy to ageExtended service lifeEngine sealsHandling discharged materialPositive pressureCooling effect

The invention discloses a dynamic sealing device for a sintered ring cooling machine trolley, comprising a trolley, a track and an air box and being characterized in that a bracket is arranged at the outer side of a baffle at the lower part of the trolley, and the upper end of a rubber belt is fixed together with the bracket through a bolt. The rubber belt provided by the invention falls on the inner side of the baffle of the air box and clings to the inner side of the baffle of the air box by means of positive pressure formed by a high-pressure blower, therefore, the sealing effect is good, the sintering ore cooling effect is ensured, the hot air quantity is increased, and the waste heat generating capacity is improved. The dynamic sealing device is simple in maintenance due to no need of arranging two sets of sealing parts on a ring cooling machine; and in addition, the temperature resistant rubber belt, and particularly a waste and old high temperature resistant conveying belt is selected instead of an expensive fluorine rubber plate, therefore, the dynamic sealing device is low in manufacturing cost, long in service life and capable of reducing replacing and maintaining workloads.

Owner:新余钢铁股份有限公司

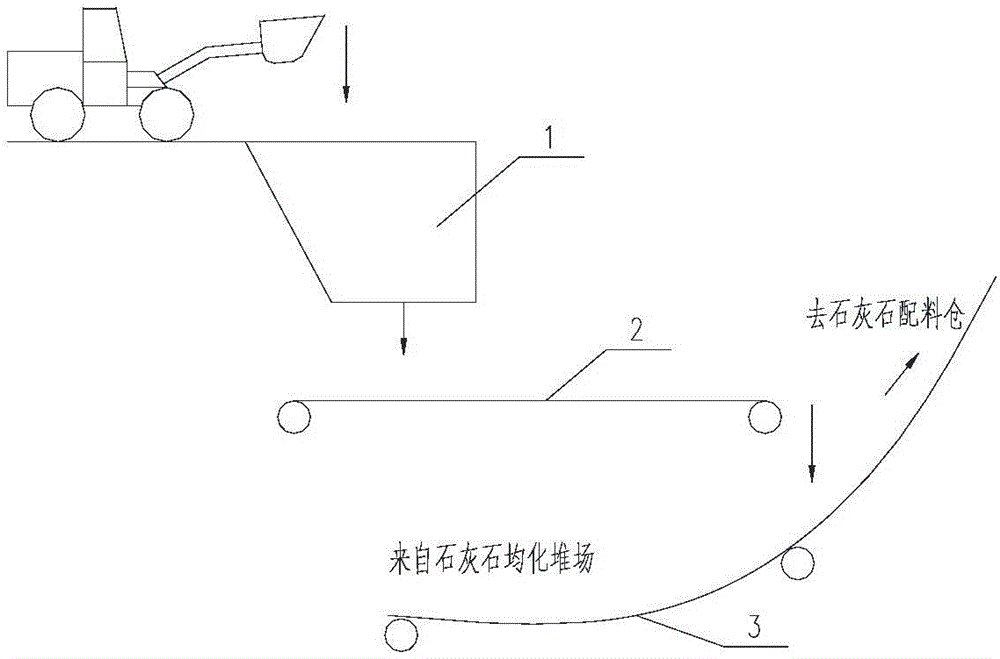

A vertical roller mill bypass classification drying raw meal preparation system and process

The invention discloses a vertical roller mill bypass graded drying raw meal preparation system, the discharge port of the raw material hoist is connected to the feed port of the vertical roller mill, and the discharge port of the vertical roller mill is connected to the mill The feed port of the tail lifter, the discharge port of the grinding tail lifter is connected to the feed port of the drying equipment, the discharge port of the drying equipment is connected to the feed port of the dry material lifter, and the discharge port of the dry material lifter Connect the inlet of the V-type powder separator of the primary classification equipment, the air outlet of the V-type powder separator is connected to the air inlet of the vortex powder separator of the final classification equipment, and the air outlet of the vortex powder separator is connected to the air inlet of the cyclone collector. The air outlet of the cyclone collector is connected to the air inlet of the circulating centrifugal fan, the air outlet of the circulating centrifugal fan is connected to the air inlet of the vertical dryer, and the air outlet of the vertical dryer is connected to a V-shaped selection The air inlet of the powder machine; the invention makes full use of the system to facilitate reasonable adjustment and control of the process parameters of the system, so as to achieve the purpose of increasing production and reducing consumption of the system.

Owner:南京圣火环境科技有限公司

System for regulating and optimizing smoke by power generation and recycle of residual heat of sintering ring cold machine

ActiveCN101655319BTake advantage ofOptimize the operation modeEnergy industryIncreasing energy efficiencyIron plantEngineering

The invention discloses a system for regulating and optimizing smoke by power generation and recycle of residual heat of a sintering ring cold machine, which mainly comprises a ring cooling machine, a ring cooling machine wind box, a ring cooling machine wind chamber, a switching baffle door, a dual-pressure boiler without resisual heat and a steam filling and condensing type dual-pressure steam turbine, wherein the ring cooling machine wind chamber is divided into a high-temperature wind chamber and a low-temperature wind chamber which are respectively connected with the dual-pressure boilerwithout resisual heat through inlet flues, the steam outlet of the dual-pressure boiler without resisual heat is connected with the steam filling and condensing type dual-pressure steam turbine, and the outlet of a sediment chamber of the dual-pressure boiler without resisual heat is connected with a circulation fan through the flues and a wind complementing door. The invention has the highest efficiency in recovering residual heat, can use the resisual heat of sintering mineral materials at most, keeps stability, high efficiency and contineous operation for power generation by using the residual heat, and has important meaning for steal and iron plants.

Owner:ZHEJIANG XIZI UNITED ENG

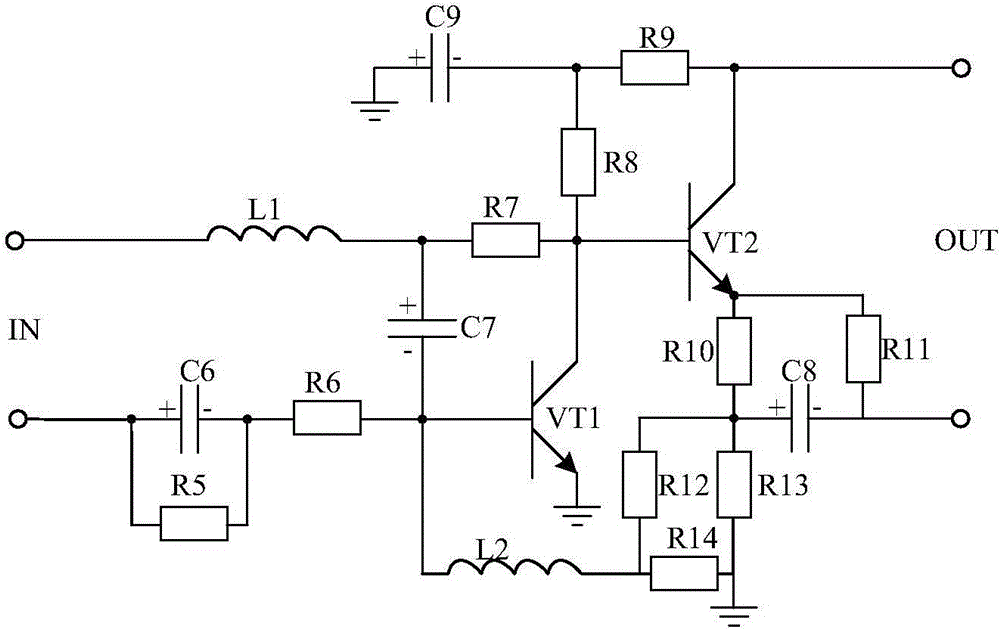

Alarm type sintering afterheat power generation system based on current limiting power supply circuit

InactiveCN104930860AImprove utilization efficiencyIncrease waste heat power generationAc-dc conversionIncreasing energy efficiencyCurrent limitingEngineering

The invention discloses an alarm type sintering afterheat power generation system based on a current limiting power supply circuit. The system comprises a sintering machine hot smoke system, a hot waste gas afterheat utilization system and a sintering afterheat power generation thermodynamic system, wherein a current limiting power supply output system connected to an output end of a turbogenerator is arranged in the sintering afterheat power generation thermodynamic system, and comprises a temperature alarm circuit, the current limiting power supply circuit and an accumulator or electric equipment connected with the current limiting power supply circuit; and the current limiting power supply circuit consists of a current limiting circuit and a power supply circuit. The system improves the product stability, prolongs the product life, and improves the internal operation circuit of the product to prevent the damage of the accumulator or the electric equipment caused by overhigh voltage fluctuation.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Method for acquiring main energy source required by supercritical carbon dioxide power generation in cement plant

InactiveCN107062920ASimple methodIndustrial applicabilityWaste heat treatmentThermal energyChemical reaction

The main energy acquisition method required for supercritical carbon dioxide power generation in cement plants, the process and equipment characteristics of high-temperature thermochemical reaction kiln systems using clinker in cement plants, and CO 2 The energy storage device directly stores part of the heat energy of strong radiation / conduction of high-temperature equipment and / or high-temperature materials, and solves the specific adverse effects caused by the high-temperature heat energy radiated / conducted by high-temperature equipment and / or high-temperature materials. The high temperature heat energy converts CO 2 Fluid conversion to high-pressure hot supercritical CO with high energy density 2 fluid, as supercritical CO 2 The main energy source for generator sets to generate electricity. The present invention solves the adverse effects of various types of high-temperature heat energy in various links in the cement clinker production process on the kiln system operating conditions, clinker cooling quality, equipment safety and staff safety, etc., and develops a supercritical CO 2 A series of high-quality high-temperature energy sources for high-efficiency power generation by the power generation system, the method is simple and has industrial practicability.

Owner:长沙紫宸科技开发有限公司

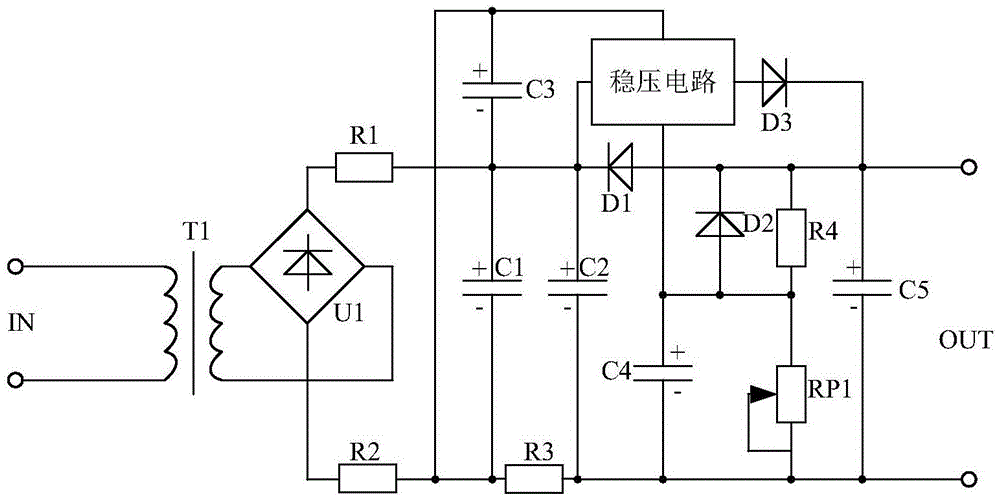

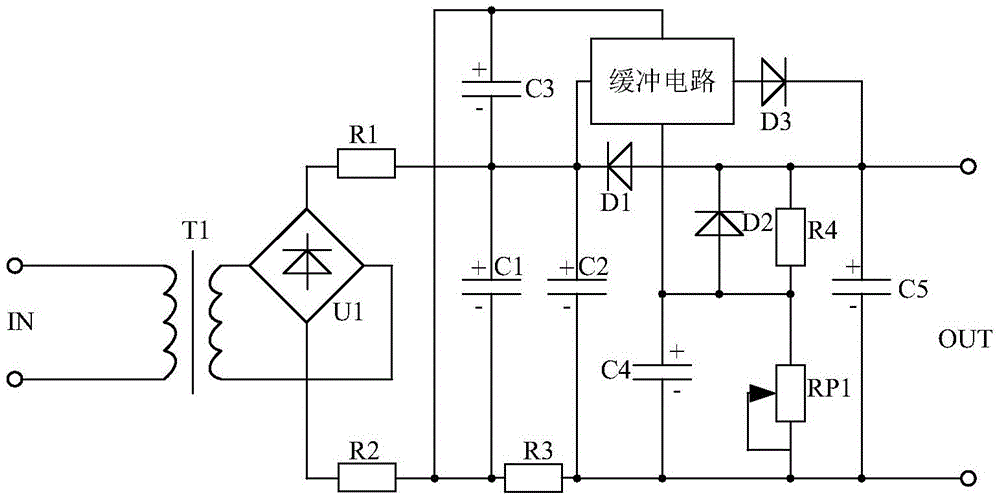

Alarming type sintering waste heat power generation system based on voltage-stabilizing power circuit

InactiveCN104896957AImprove utilization efficiencyIncrease waste heat power generationAc-dc conversion without reversalIncreasing energy efficiencyPower circuitsDynamo

The invention discloses an alarming type sintering waste heat power generation system based on a voltage-stabilizing power circuit. The alarming type sintering waste heat power generation system based on the voltage-stabilizing power circuit comprises a sintering machine hot flue gas system, a hot exhaust gas waste heat utilizing system, and a sintering waste heat power generation thermodynamic system. A voltage-stabilizing power output system connected to the output end of a turbogenerator is further arranged in the sintering waste heat power generation thermodynamic system, and the voltage-stabilizing power output system comprises a temperature alarming circuit, the voltage-stabilizing power circuit and a storage battery or electric equipment connected with the voltage-stabilizing power circuit. The voltage-stabilizing power circuit is composed of a voltage-stabilizing circuit and a power circuit. By means of the sintering waste heat power generation system, the stability of the product is improved, the service life of the product is prolonged, the circuits running in the product are added and modified, and the situation that because voltage fluctuation is too high, the storage battery or the electric equipment is damaged is avoided.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

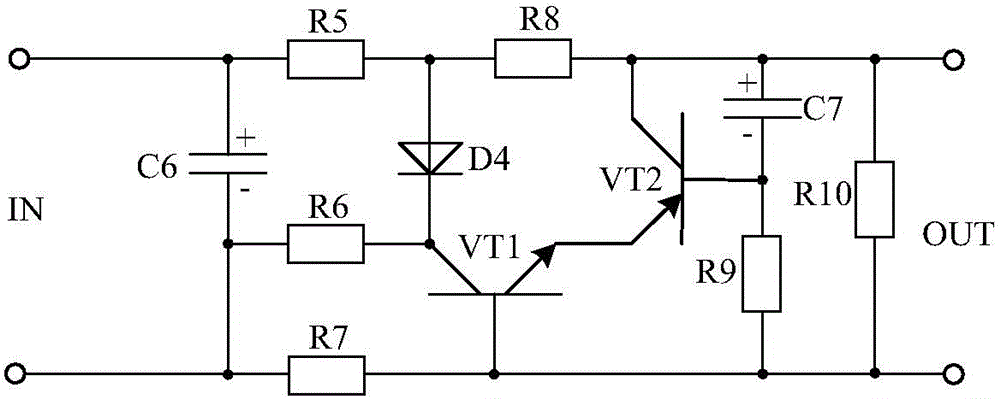

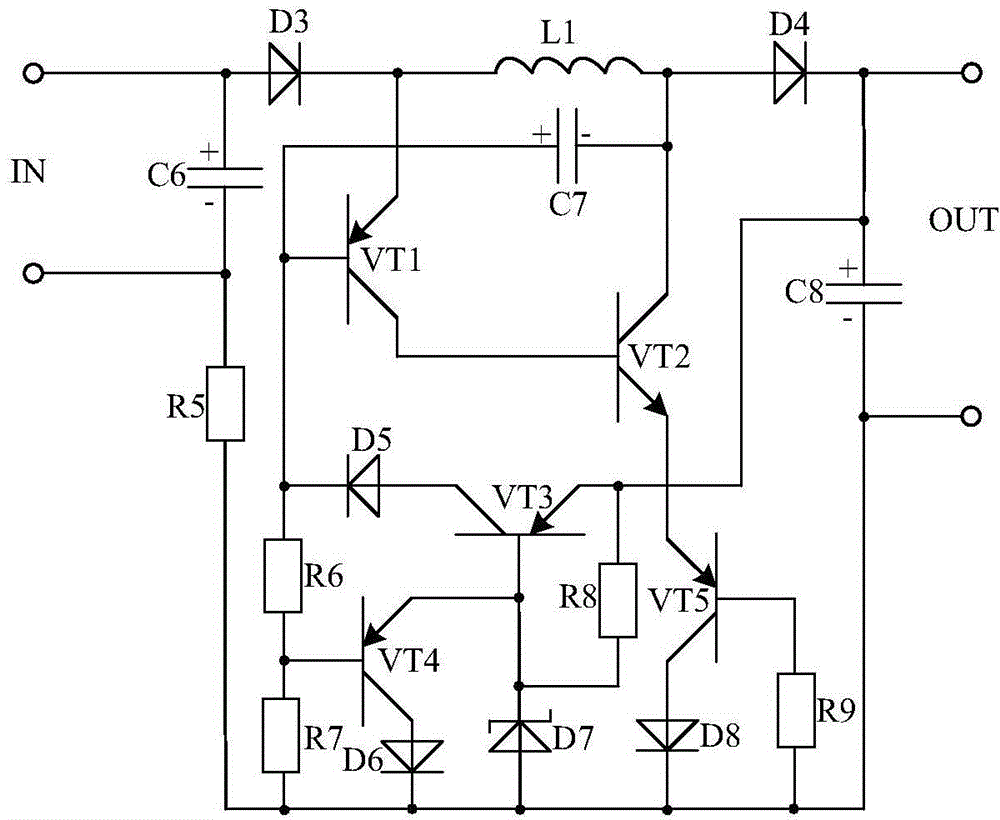

Alarming type sintering waste heat power generating system based on boosting power circuit

InactiveCN104864727AImprove utilization efficiencyIncrease waste heat power generationEnergy industryIncreasing energy efficiencyEngineeringPower circuits

The invention discloses an alarming type sintering waste heat power generating system based on a boosting power circuit. The alarming type sintering waste heat power generating system comprises a sintering machine hot smoke system, a hot exhaust gas waste heat utilizing system and a sintering waste heat power generating thermodynamic system. The sintering waste heat power generating thermodynamic system is internally provided with a boosting power output system connected to the output end of a steamer power generator. The boosting power output system comprises a temperature alarming circuit, the boosting power circuit and a storage battery or an electric device connected with the boosting power circuit. The boosting power circuit is composed of a boosting circuit and a power circuit. The stability of the alarming type sintering waste heat power generating system is improved, the service life of the alarming type sintering waste heat power generating system is prolonged, the internal running circuits of the alarming type sintering waste heat power generating system are additionally arranged or changed, and storage battery damage or electric device damage caused by too high fluctuation of voltage is avoided.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Sintering waste heat power generating system based on boosting power circuit

InactiveCN104864728AImprove utilization efficiencyIncrease waste heat power generationEnergy industryIncreasing energy efficiencyEngineeringExhaust gas

The invention discloses a sintering waste heat power generating system based on a boosting power circuit. The sintering waste heat power generating system comprises a sintering machine hot smoke system, a hot exhaust gas waste heat utilizing system and a sintering waste heat power generating thermodynamic system. The sintering waste heat power generating thermodynamic system is internally provided with a boosting power output system connected to the output end of a steamer power generator. The boosting power output system comprises the boosting power circuit and a storage battery or an electric device connected with the boosting power circuit. The boosting power circuit is composed of a boosting circuit and a power circuit. The stability of the sintering waste heat power generating system is improved, the service life of the sintering waste heat power generating system is prolonged, the internal running circuits of the sintering waste heat power generating system are additionally arranged or changed, and storage battery damage or electric device damage caused by too high fluctuation of voltage is avoided.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Siphon air cooling method and equipment for tower type solar thermal power generation device

InactiveCN102562502BImprove reliabilityReduce usageFrom solar energySteam engine plantsCollector deviceEngineering

The invention discloses a siphon air cooling method for a tower-type solar heat power generation device. A cylindrical condenser is used in the method, and the bottom and the upper end of the cylindrical condenser are respectively provided with an air inlet passage and an air outlet passage; the air inlet passage, the inner part of the cylindrical condenser and the air outlet passage form an air flue; and an exhaust steam condenser in the air flue is cooled by using the heat siphon effect. The tower-type solar heat power generation device manufactured by the method consists of a reflector array, a vertical tower, a tower top heat collector, a steam turbine and the cylindrical condenser. The device is characterized in that: the bottom of the cylindrical condenser is provided with the air inlet passage, and the upper end of the cylindrical condenser is provided with the air outlet passage; and the exhaust steam condenser of the solar heat power generation device is arranged in the cylindrical condenser. The air inlet passage, the inner part of the cylindrical condenser and the air outlet passage form the air flue with low air resistance. The invention has the advantages that: power is not required in heat siphon air cooling, cooling water is not required, the construction land can be reduced, the investment is reduced, the operating cost and the internal power utilization are reduced, and the reliability is improved. Four embodiments are shown in attached figures.

Owner:XUZHOU FENGTONG INFORMATION TECH CO LTD

Coal-burning combustion-supporting sulfur-fixing agent

The invention discloses a fuel coal combustion-supporting sulfur fixing agent which is prepared from the following components in parts by weight: 2 to 6 parts of nitrate, 10 to 15 parts of ferrocenium tetrafluoroborate, 0 to 3 parts of industrial edible salt, 2 to 6 parts of calcium glycinate, 2 to 4 parts of a sulfur fixing agent, 0.5 to 2 parts of carboxylate, 6 to 8 parts of a surfactant and 100 parts of water.

Owner:辽宁天宝华瑞建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com