A dynamic sealing device for a sintering ring cooler

A sintered ring cooler and dynamic sealing technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems that the fluorine rubber plate is easy to age, crack and fall off, affect the cooling effect of sinter, and the dust pollution of equipment, etc., and achieve reduction Replacing the maintenance workload, increasing waste heat power generation, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

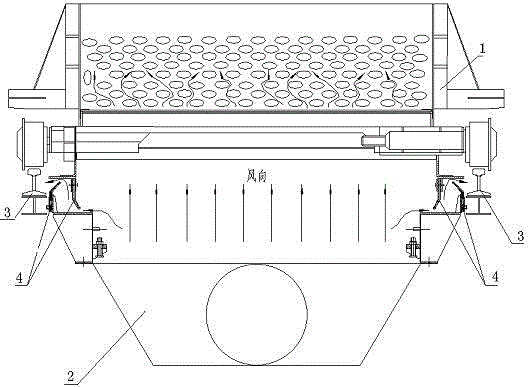

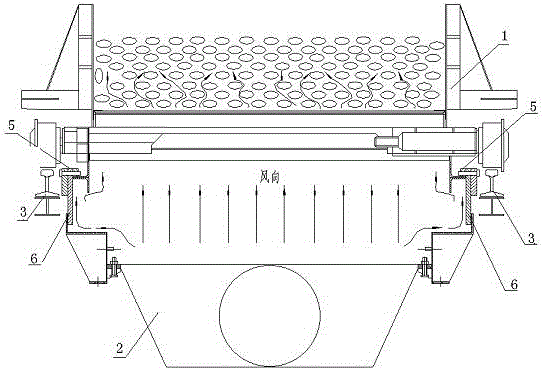

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments. Such as figure 1 As shown, the sintering ring cooler is generally equipped with 45-80 trolleys 1 and 12-26 bellows 2 according to the sinter output scale, and the bellows 2 are all arranged on the air duct of the ring cooler. The trolley 1 runs on the track 3. There is a gap between the trolley 1 and the bellows 2. The fluorine rubber plate 4 is installed on the outside of the bellows 2 baffle and under the baffle of the trolley 1. The fluorine rubber plate 4 cannot withstand the high temperature environment for a long time and is aging and cracking. Falling off, thereby causing part of the air volume to escape from the gap between the trolley 1 and the bellows 2, and the sealing effect is greatly reduced. Such as figure 2 Shown, support 5 is welded on the outside of trolley 1 lower baffle plate, and support 5 adopts angle steel or channel steel to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com