Production equipment and preparation method of nano environment-friendly fire coal combustion-supporting sulfur-fixing agent

A technology for production equipment and sulfur-fixing agent is applied in the production equipment and preparation field of nano-environmentally-friendly coal-fired combustion-supporting sulfur-fixing agent to achieve the effects of reducing smoke and dust emissions, enhancing production efficiency and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

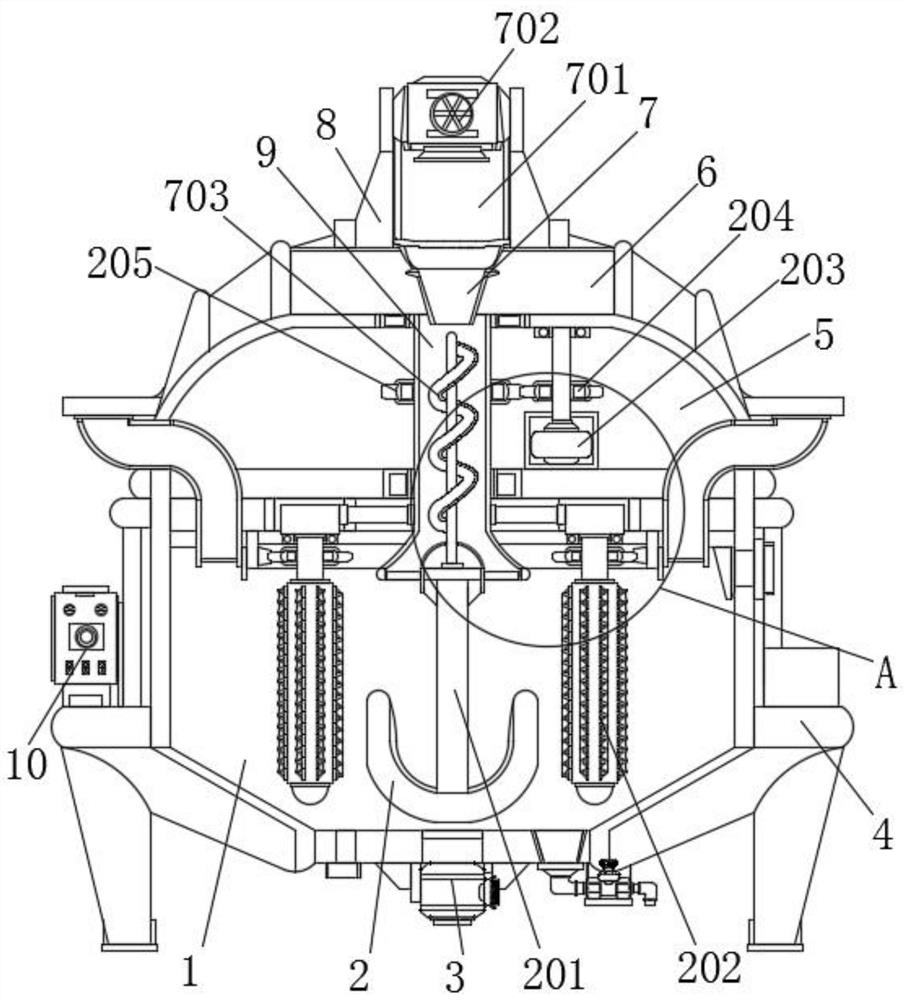

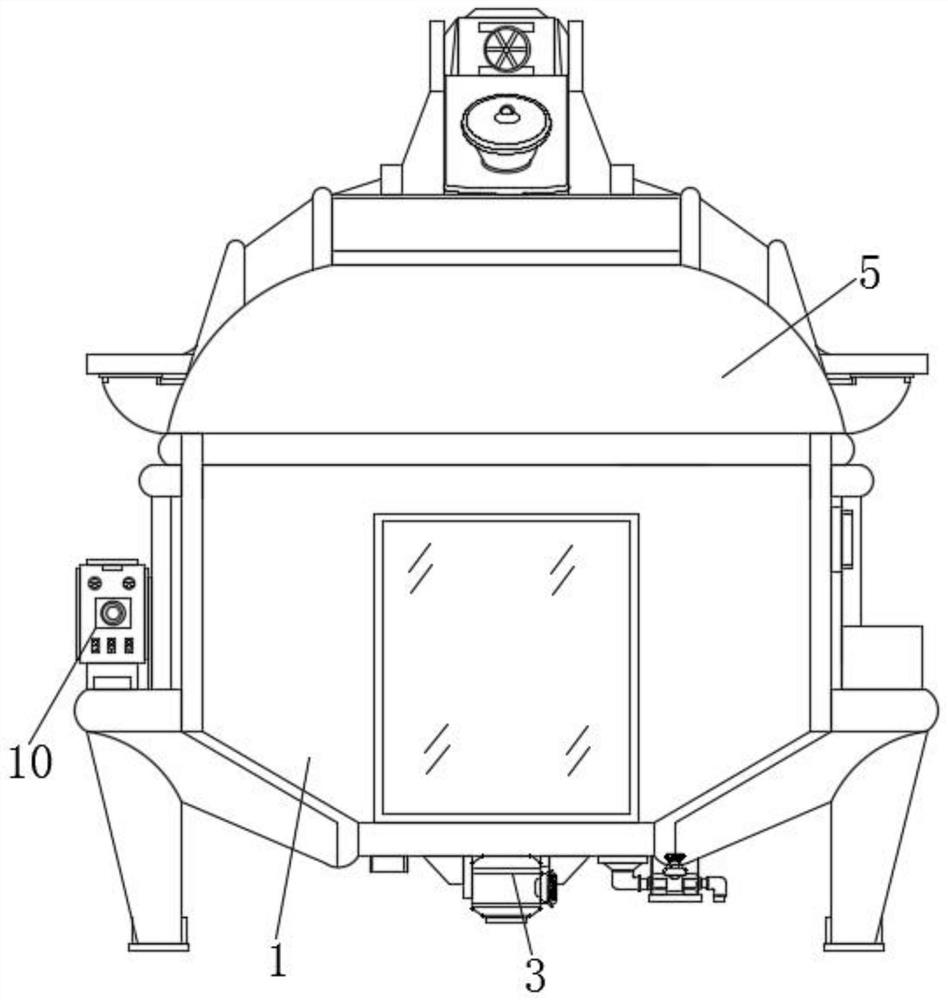

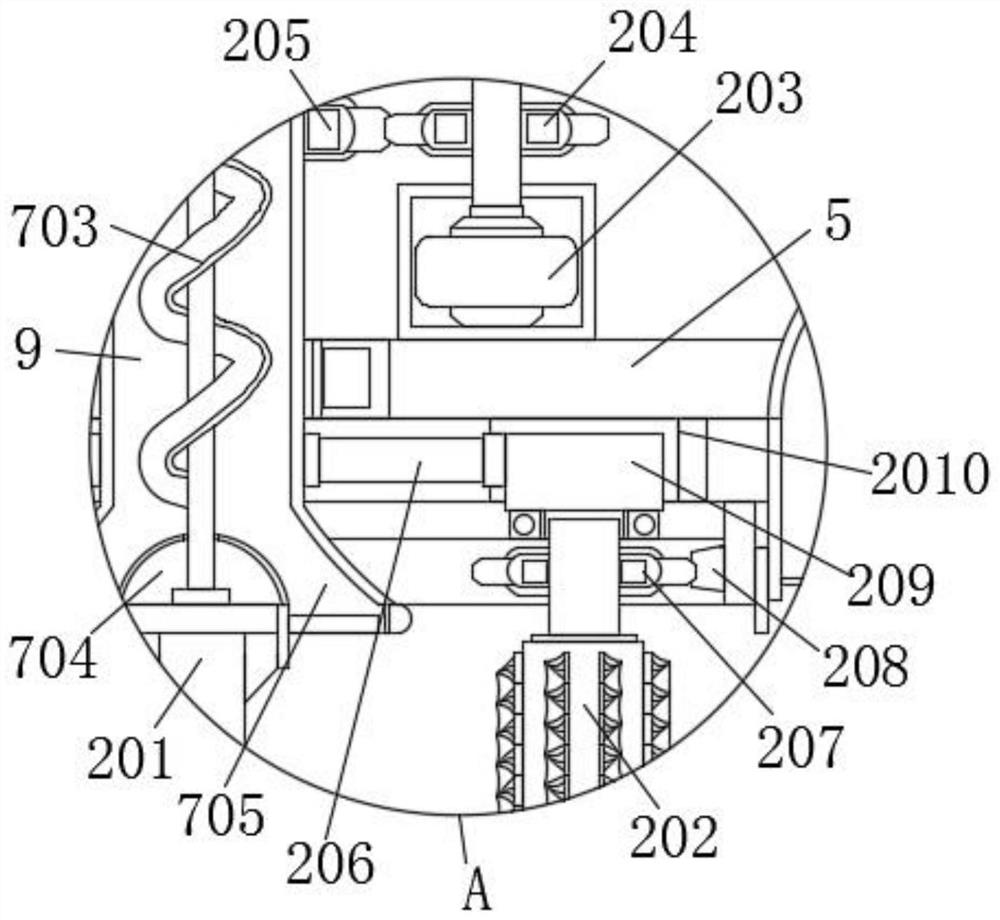

[0032] see Figure 1-7, the present invention provides a technical solution: a nano-environmentally friendly coal-fired combustion-supporting sulfur-fixing agent production equipment and its preparation method, comprising a reactor body 1, the top of the reactor body 1 is provided with a top groove 5, and the top of the top groove 5 is provided with There is an installation groove 6, the two sides of the top of the installation groove 6 are provided with connecting frames 8, the middle position inside the installation groove 6 is provided with a powder guide assembly, the bottom of both sides of the reaction kettle body 1 is provided with a fixing seat 4, and the reaction kettle The middle position of the bottom of the body 1 is provided with a liquid pump 3 communicating with each other, the top and bottom of the top tank 5 are provided with sleeves 9, one side of the top tank 5 is provided with a mixing assembly, and a set of fixed seats 4 A console 10 is arranged on the top...

Embodiment 2

[0036] see Figure 1-7 , the present invention provides a technical solution: a nano-environmentally friendly coal-fired combustion-supporting sulfur-fixing agent production equipment and its preparation method, comprising a reactor body 1, the top of the reactor body 1 is provided with a top groove 5, and the top of the top groove 5 is provided with There is an installation groove 6, the two sides of the top of the installation groove 6 are provided with connecting frames 8, the middle position inside the installation groove 6 is provided with a powder guide assembly, the bottom of both sides of the reaction kettle body 1 is provided with a fixing seat 4, and the reaction kettle The middle position of the bottom of the body 1 is provided with a liquid pump 3 communicating with each other, the top and bottom of the top tank 5 are provided with sleeves 9, one side of the top tank 5 is provided with a mixing assembly, and a set of fixed seats 4 A console 10 is arranged on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com