A method for improving the grindability of cement raw meal and reducing toc emission by using kitchen waste

A technology for cement raw meal and kitchen waste, applied in cement production, clinker production and other directions, can solve the problem of not suppressing TOC emission, etc., and achieve the effects of promoting crack propagation, suppressing emission, and improving grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

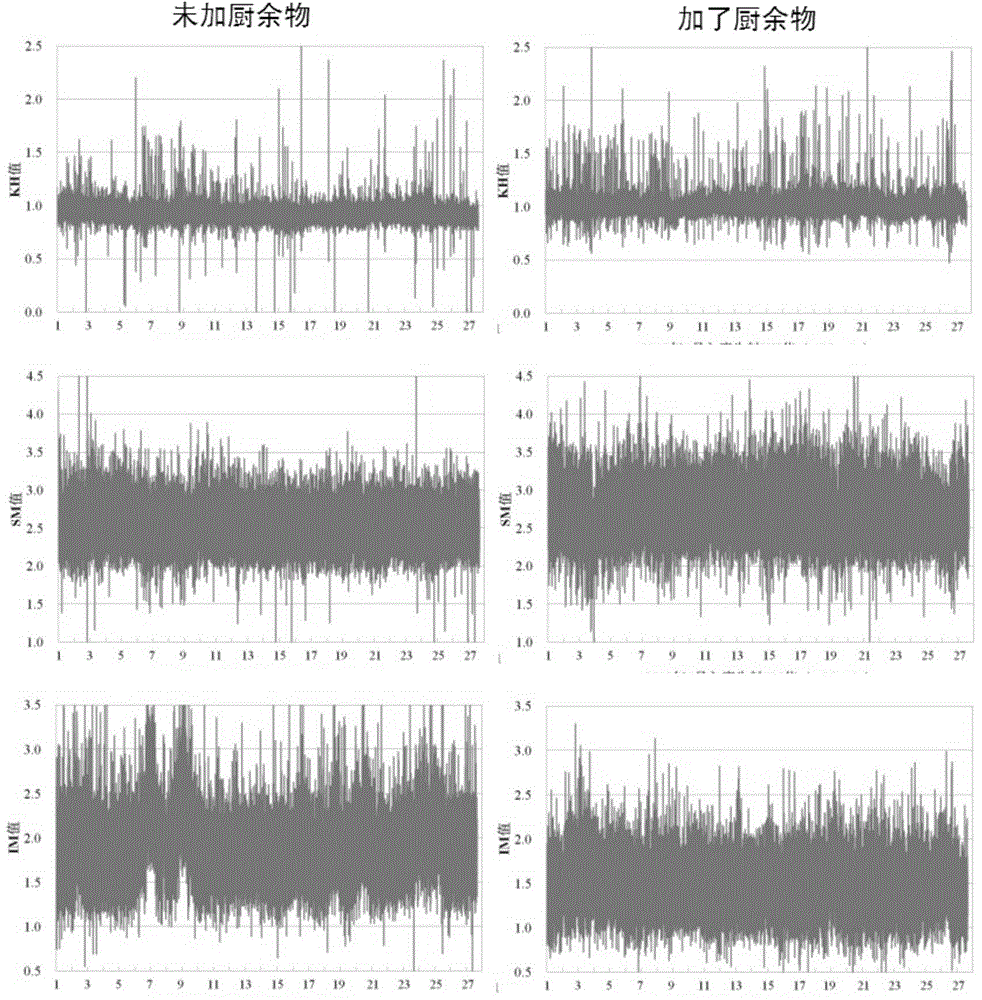

[0024] Small-scale test: small-scale vertical mill experimental platform, the feed rate of raw meal is 150kg / h, and the amount of kitchen waste added is 15kg / h. After fully mixing the kitchen residues separated from municipal solid waste with limestone, clay, iron ore and other raw materials required for raw meal preparation, they are sent to a small vertical mill experimental platform for grinding, and are mixed with no kitchen waste under the same conditions. The comparison of the grinding experiment of the residue. The results showed that after adding kitchen waste, the power consumption of the small vertical mill experimental platform was reduced by 1.2 degrees / ton of raw meal.

specific Embodiment approach

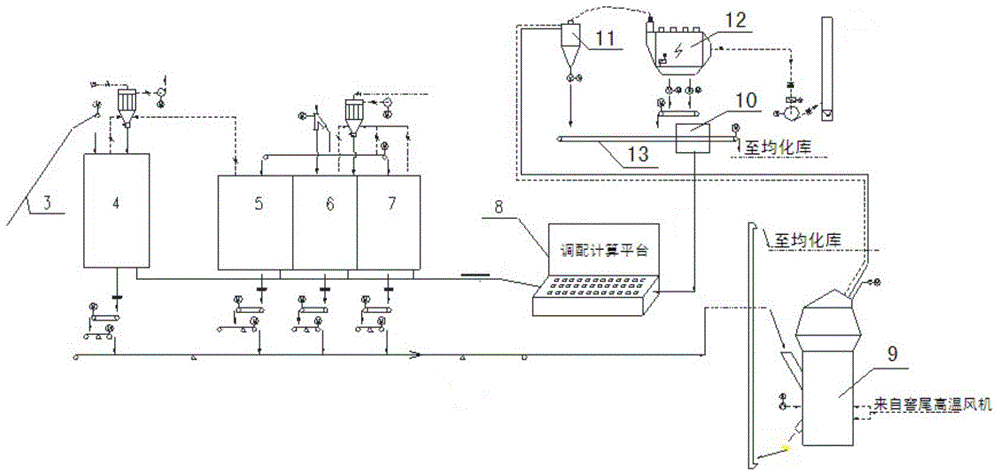

[0026] For a 5000t / d cement clinker production line, the raw material feed rate of the supporting vertical mill is 420t / h. The specific implementation is as follows:

[0027] 1) According to the requirements of raw material preparation in the cement production process, determine the chemical composition of the kitchen waste sorted from municipal solid waste; the chemical composition (dry basis, %) of the kitchen waste in a certain domestic city is shown in Table 1 below:

[0028] Table 1

[0029] loss

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 o

Na 2 o

SO 3

Cl -

52.10

27.09

4.74

3.10

6.50

0.88

1.20

1.20

0.31

1.05

[0030] The results show that the ash formed after the incineration of kitchen waste is mainly composed of SiO 2 , can be used to replace clay raw materials.

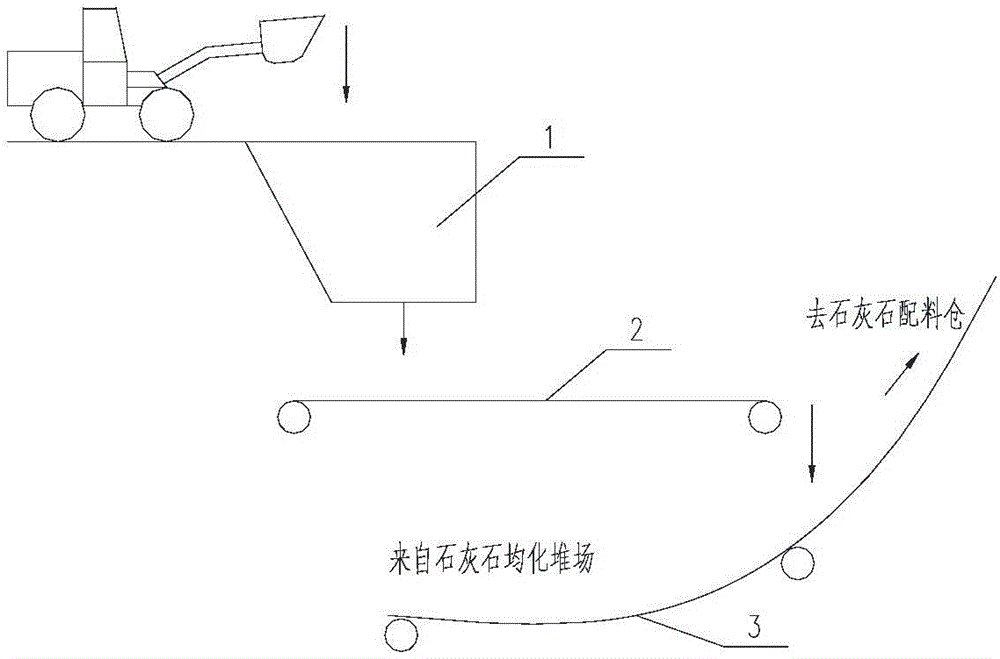

[0031] 2) After the food waste enters the cement plant, it is stacked in the food waste storage pit 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com