Cyclone separating barrel and cleaning system and combine harvester using cyclone separating barrel

A cyclone separation and cleaning technology, which is applied in the fields of application, agricultural machinery and implements, threshing equipment, etc., can solve the problems of increased size of the miscellaneous suction fan, reduced reliability of the whole machine, and increased vibration of the whole machine, so as to reduce the speed, Guarantee the cleaning ability and reduce the effect of tremor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

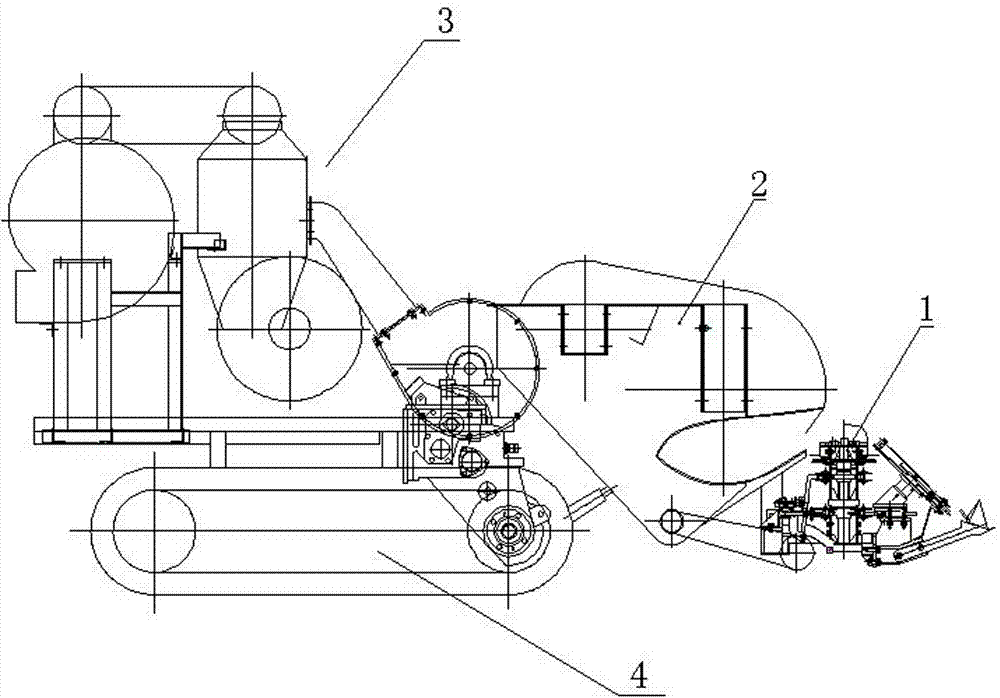

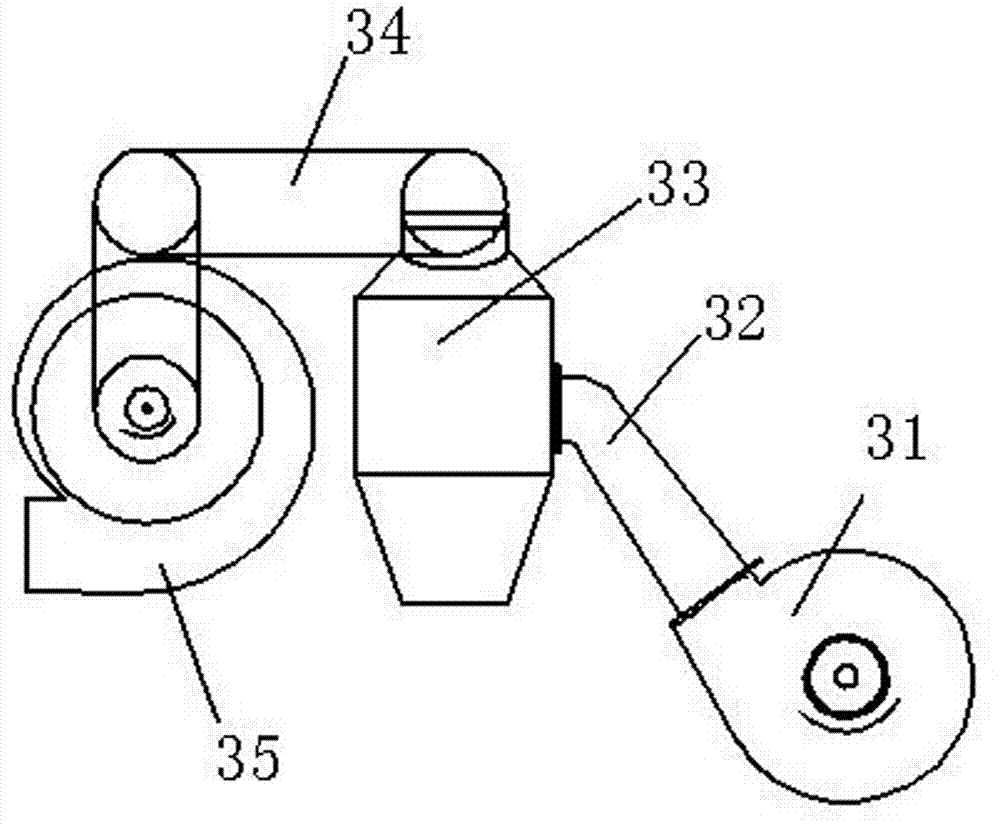

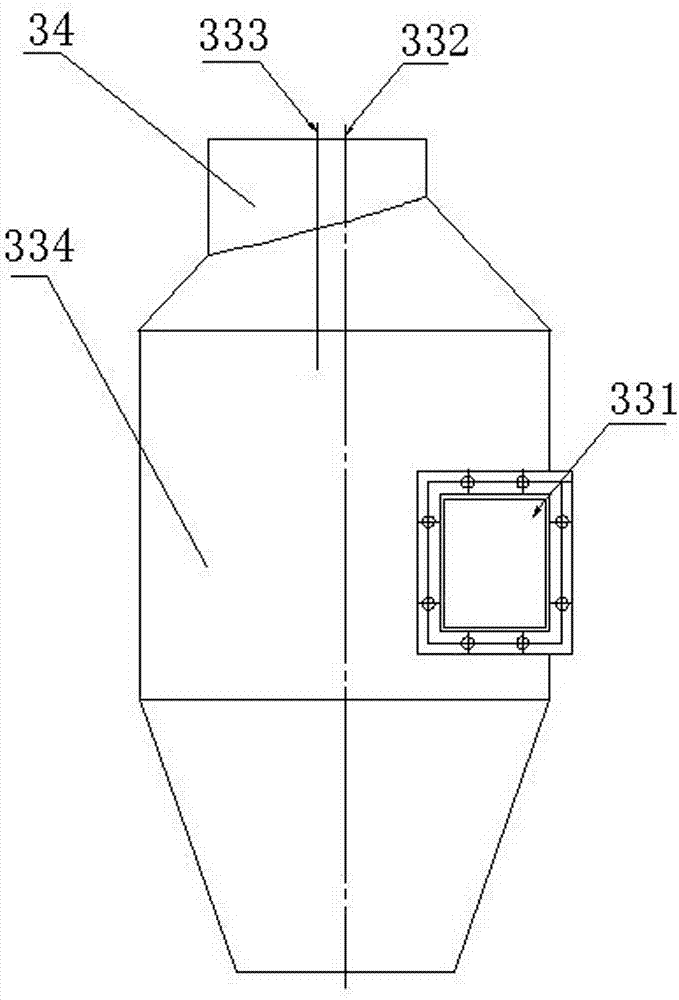

[0022] The embodiment of the combine harvester of the present invention: such as Figure 1 ~ Figure 4 As shown, the combine harvester includes a frame 4, and the frame 4 is provided with a header 1, a threshing drum 2 and a cleaning system 3, wherein the header and the separation drum are the same as those in the prior art. The cleaning system includes Cyclone separation cylinder 33. Cyclone separation cylinder 33 includes a cylinder 334 with a central axis extending in the up and down direction. The upper and lower ends of the cylinder are open. The cylinder 334 includes a cylinder section and an upper part that is coaxially arranged with the cylinder part. The cone section and the lower cone section with a large upper and a small lower cone. The upper cone section is arranged above the cylinder section, the lower cone section is arranged below the cylinder section, and the lower end of the cylinder 334 is opened on the lower end surface of the lower cone section. The grain ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com