Double-cone centrifugal cleaning fan

A centrifugal and double-cone technology, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of uneven cleaning load and uneven distribution of extruded materials, and achieve reduced cleaning losses, simple structure, and easy work. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

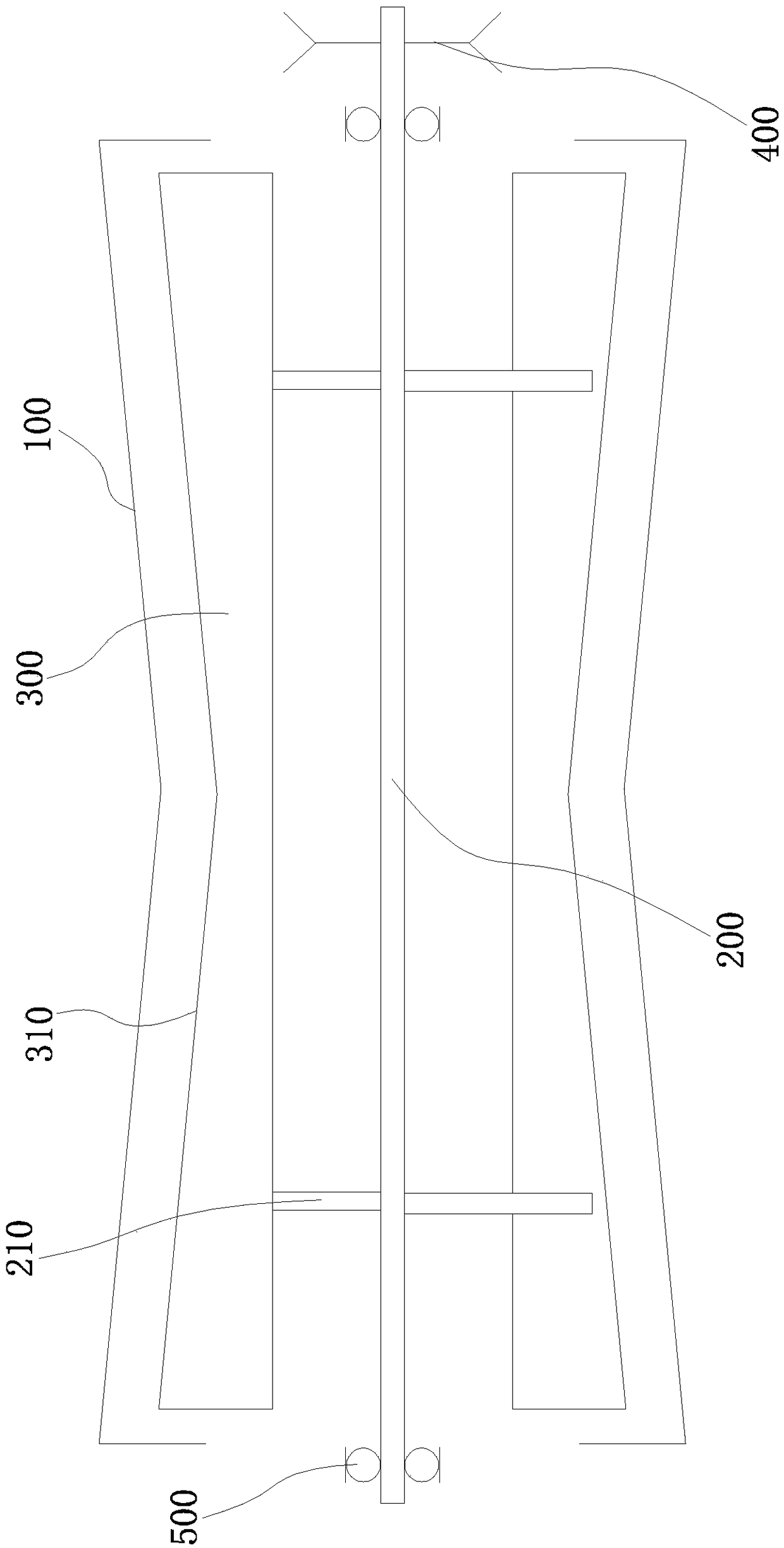

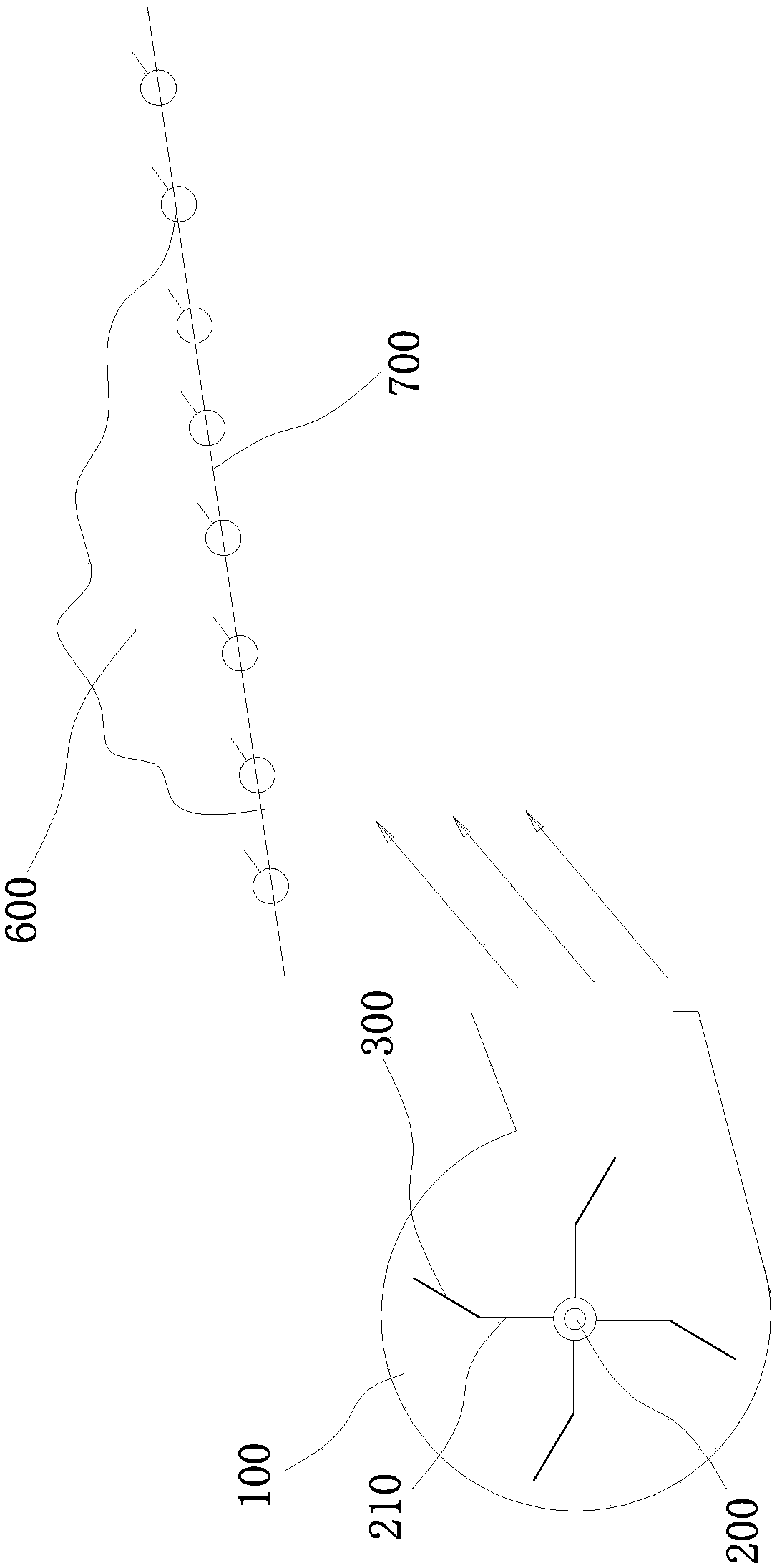

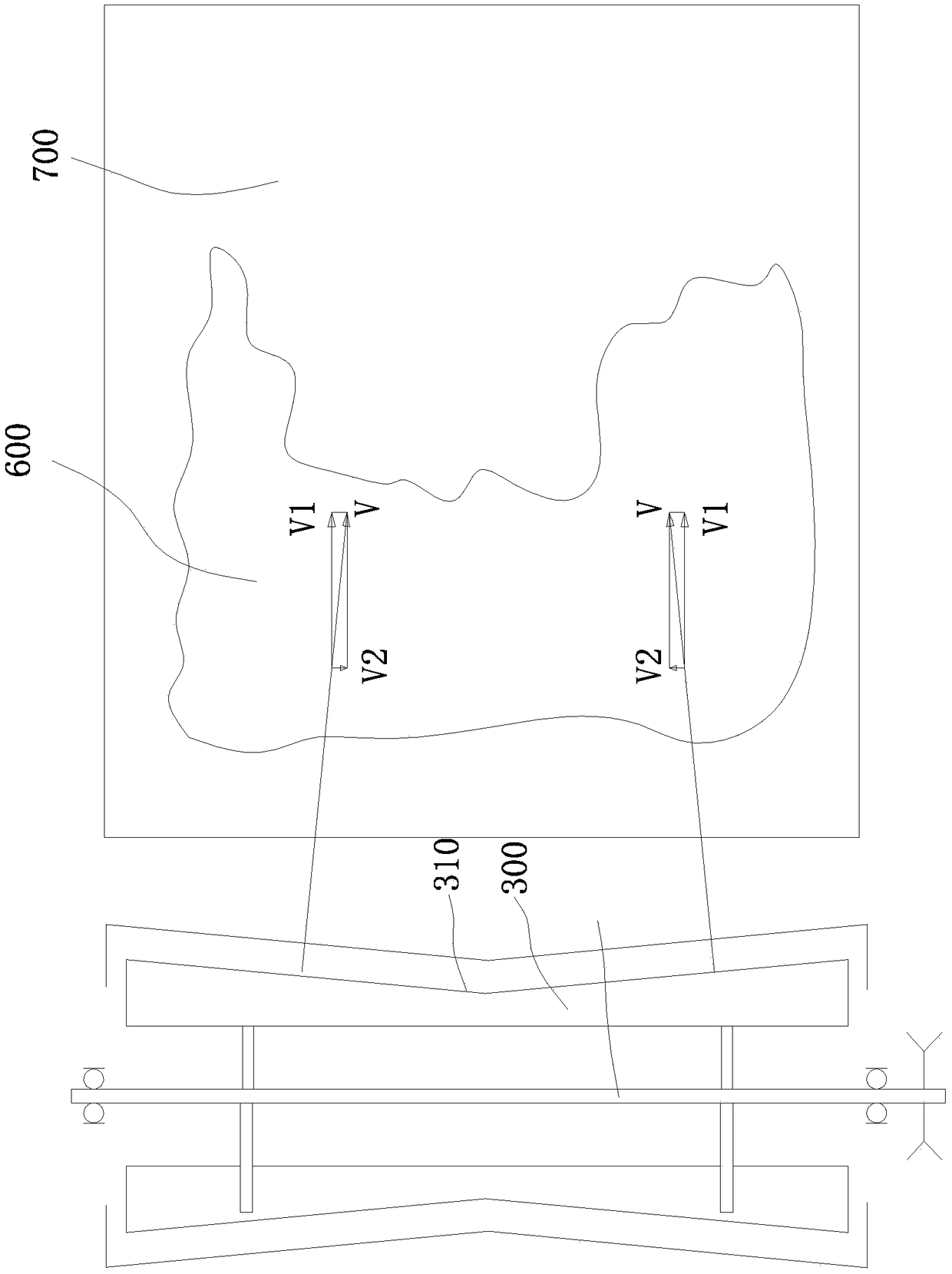

[0025] like figure 1 , figure 2 , image 3 Shown, a kind of double-cone type centrifugal cleaning fan comprises: fan housing 100, fan shaft 200 and fan blade 300, this double-cone type centrifugal type cleaning fan is applied to the semi-feeding rice-wheat combine harvester In the cleaning device, it is designed for the actual load on the vibrating screen surface.

[0026] Preferably, the fan casing 100 is exactly a casing structure, which is used to be arranged under the upper screen 700 (louver screen), and is used to blow the airflow to the upper screen 700; and the fan casing 100 includes two left and right axial air inlets , also includes a radial air outlet.

[0027] The fan shaft 200 is arranged in the fan hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com