A Harvester Material Distribution Adjustment Mechanism

A material distribution and adjustment mechanism technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as uneven distribution, lower harvesting efficiency of harvesters, and influence on cleaning effects, and achieve simple structural design and reduce Effects of cleaning loss and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

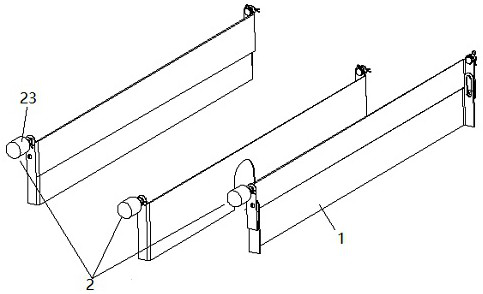

[0033] Embodiment one: if figure 1 As shown, this embodiment provides a harvester material distribution adjustment mechanism, which is arranged between the arc-shaped concave plate of the harvester and the upper screen below, including a plurality of adjustment plates 1 and angle adjustment mechanisms 2, the adjustment plate 1. Arranged along the axial direction of the arc-shaped concave plate, a plurality of the above-mentioned adjusting plates 1 are distributed at the lower part of the above-mentioned arc-shaped concave plate at intervals along the circumferential direction, and are suspended below the above-mentioned arc-shaped concave plate. The above-mentioned angle adjustment mechanism 2 and the multiple The above-mentioned adjusting plates 1 are connected by transmission, and are used to drive each of the above-mentioned adjusting plates 1 to swing around their suspension points with the above-mentioned arc-shaped concave plate toward the two ends of the above-mentioned ...

Embodiment 2

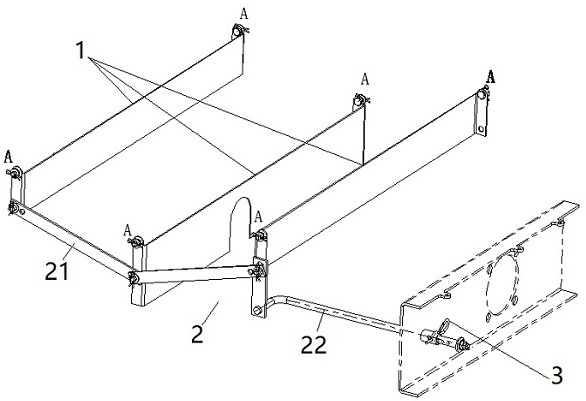

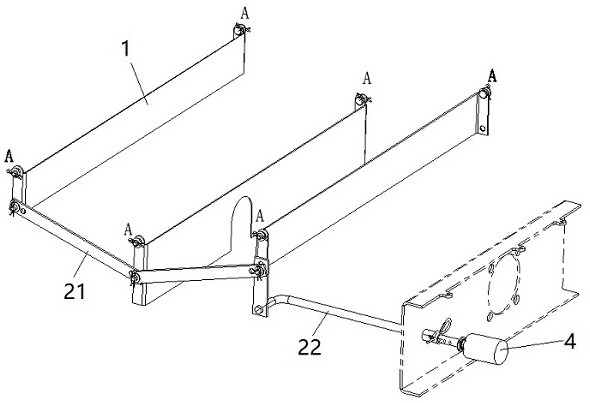

[0044] Embodiment two: if figure 2 As shown, this embodiment provides a harvester material distribution adjustment mechanism, which is arranged between the arc-shaped concave plate of the harvester and the upper screen below, including a plurality of adjustment plates 1 and angle adjustment mechanisms 2, the adjustment plate 1. Arranged along the axial direction of the arc-shaped concave plate, a plurality of the above-mentioned adjusting plates 1 are distributed at the lower part of the above-mentioned arc-shaped concave plate at intervals along the circumferential direction, and are suspended below the above-mentioned arc-shaped concave plate. The above-mentioned angle adjustment mechanism 2 and the multiple The above-mentioned adjusting plate 1 is in transmission connection, and is used to drive each of the above-mentioned adjusting plate 1 around its suspension point with the above-mentioned curved concave plate ( figure 2 , image 3 Point A in all refers to the hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com