Unequal-amplitude material cleaning sieve

A cleaning screen, non-constant amplitude technology, applied in the field of cleaning screen, can solve the problems of different amplitudes, can not achieve dispersed materials, etc., achieve diversification of vibration directions, improve screening efficiency and screening effect, and trouble-free operation for a long time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the structure, characteristics and other purposes of the present invention, now in conjunction with the attached preferred embodiments are described in detail as follows:

[0023] Embodiments of the present invention are implemented as follows:

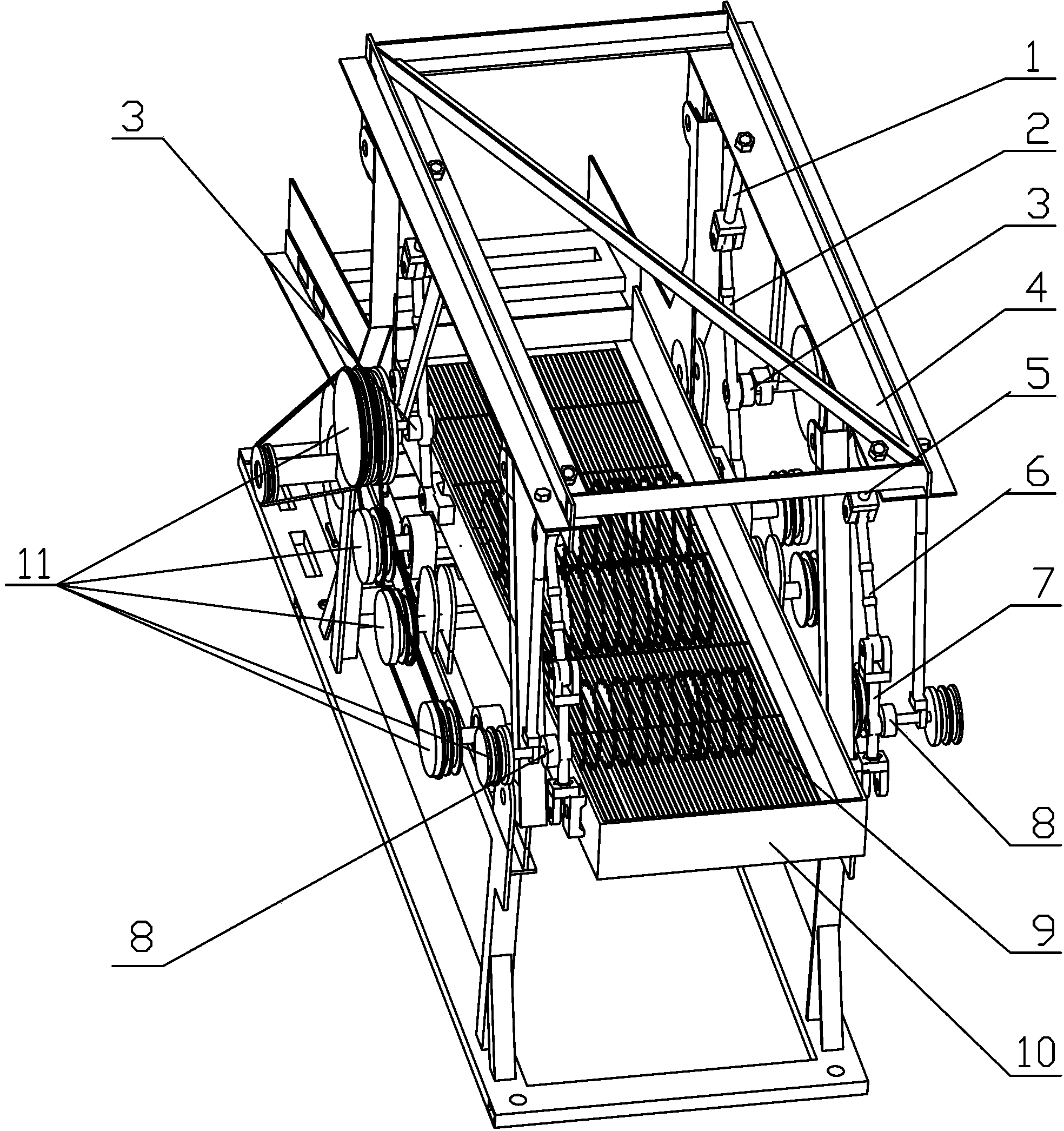

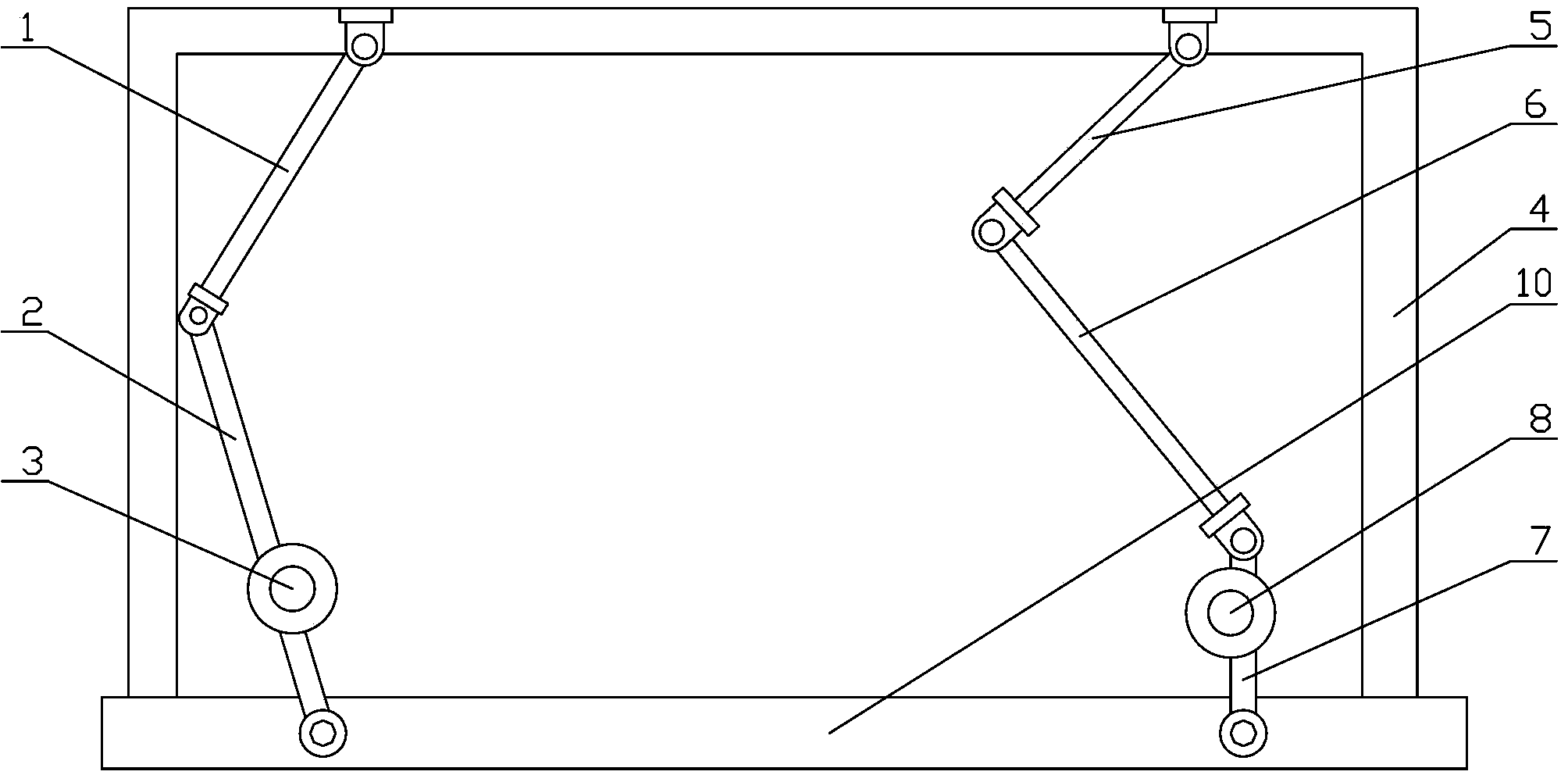

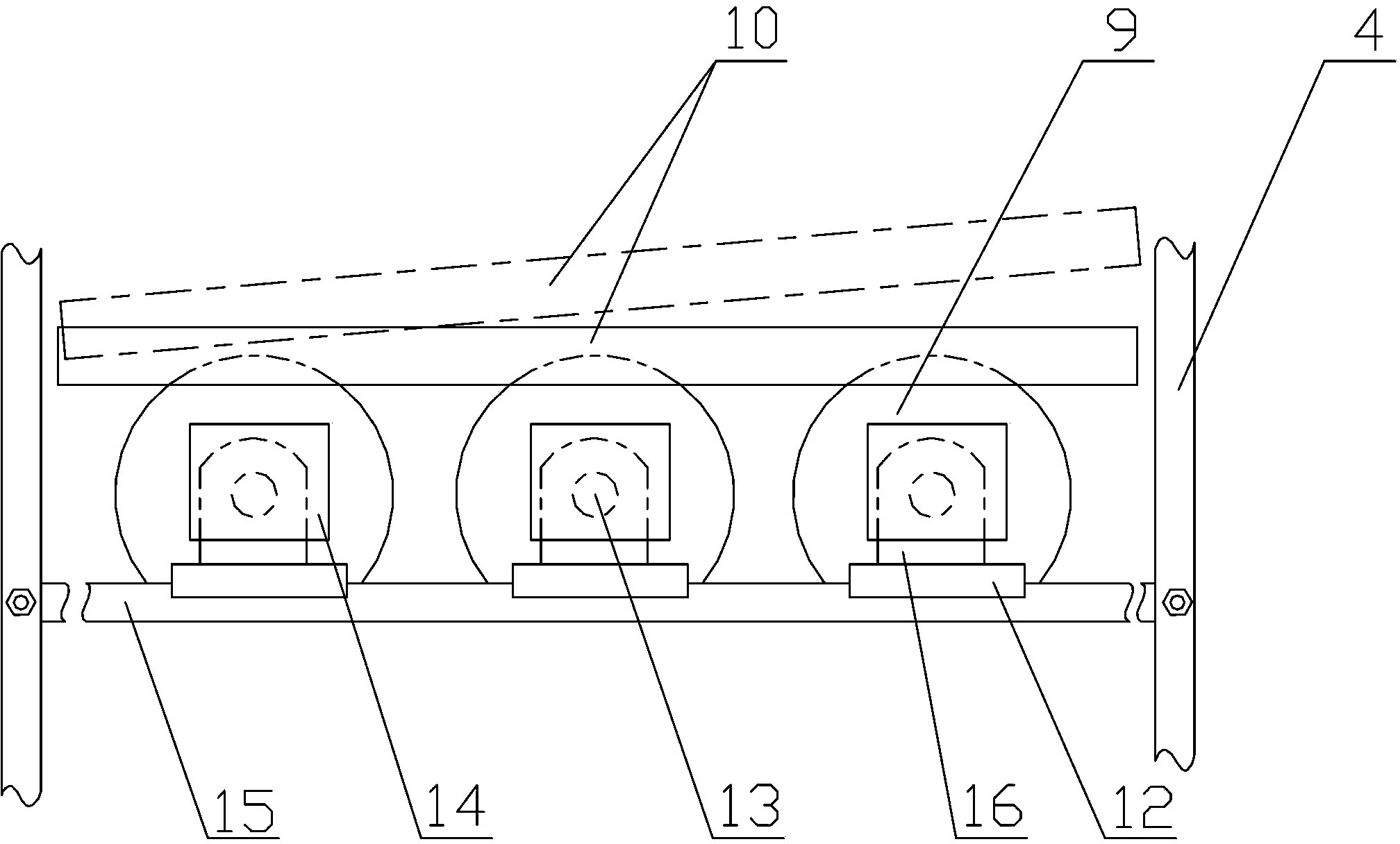

[0024] A non-uniform material cleaning screen, comprising a frame 4, a motor, a vibrating screen 10, a feed port, a discharge port, an anti-blocking crushing mechanism and a vibration mechanism, and the motor and the vibration mechanism are respectively fixed on the frame 4 Above, the front end and the rear end of the vibrating screen 10 are respectively connected to the vibrating mechanism, and the vibrating mechanism is connected to the motor through the transmission mechanism 11 .

[0025] Described vibration mechanism comprises a pair of front eccentric wheels 8, a pair of rear eccentric wheels 3, a pair of front multi-stage connecting rods and a pair of rear multi-stage connecting rods, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com