Synchronous different-amplitude embedment kneading type grain repeated husking and impurity removal vibrating screen

A technology of synchronous vibration and vibrating sieve, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve the problems of increased impurity content of isolates, large broken ear size, and blockage of sieve holes, so as to improve vibratory sieving Effect of quality and efficiency, reduction of cleaning loss, optimization of operation form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further set forth the technical scheme of the present invention and its working process, in conjunction with the accompanying drawings, the specific embodiments of the present invention are as follows:

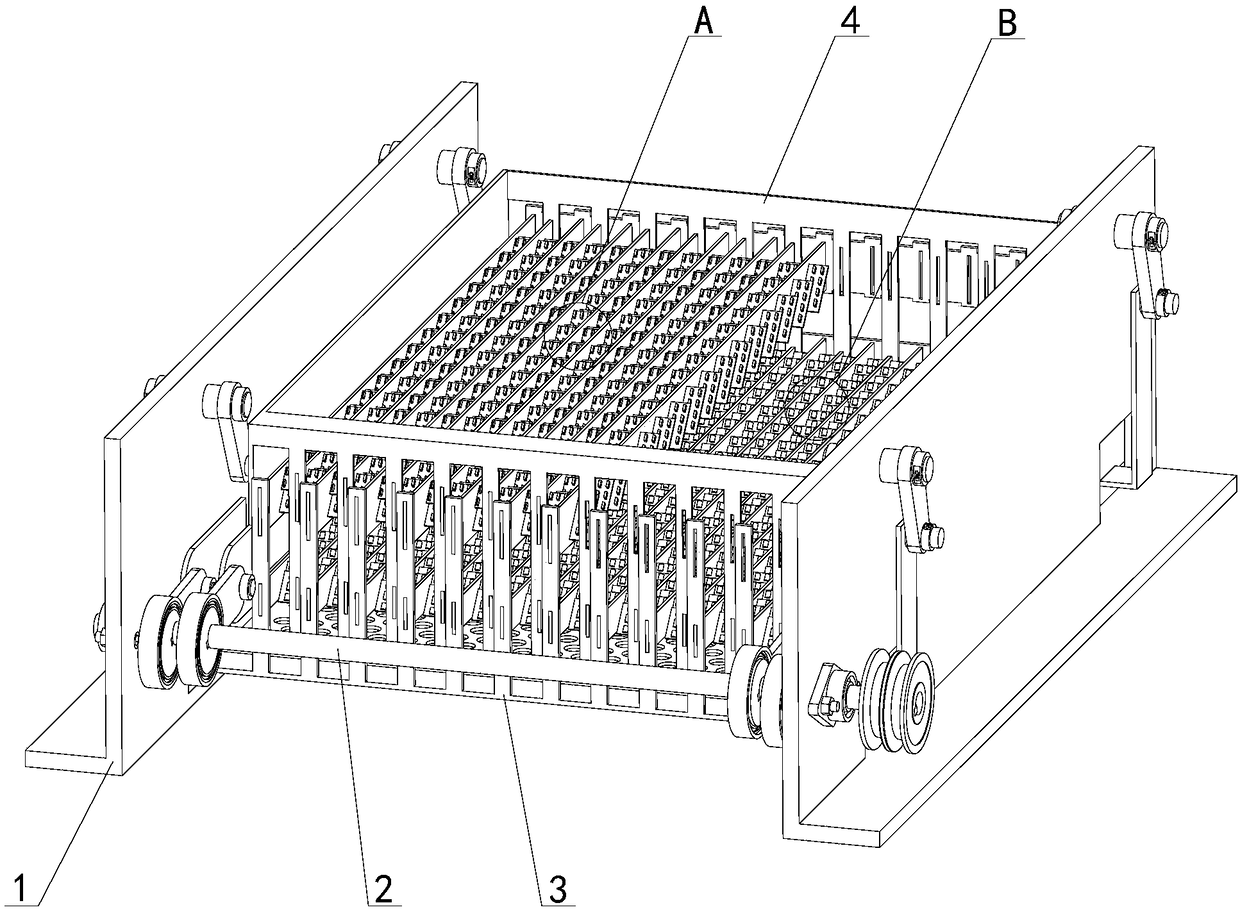

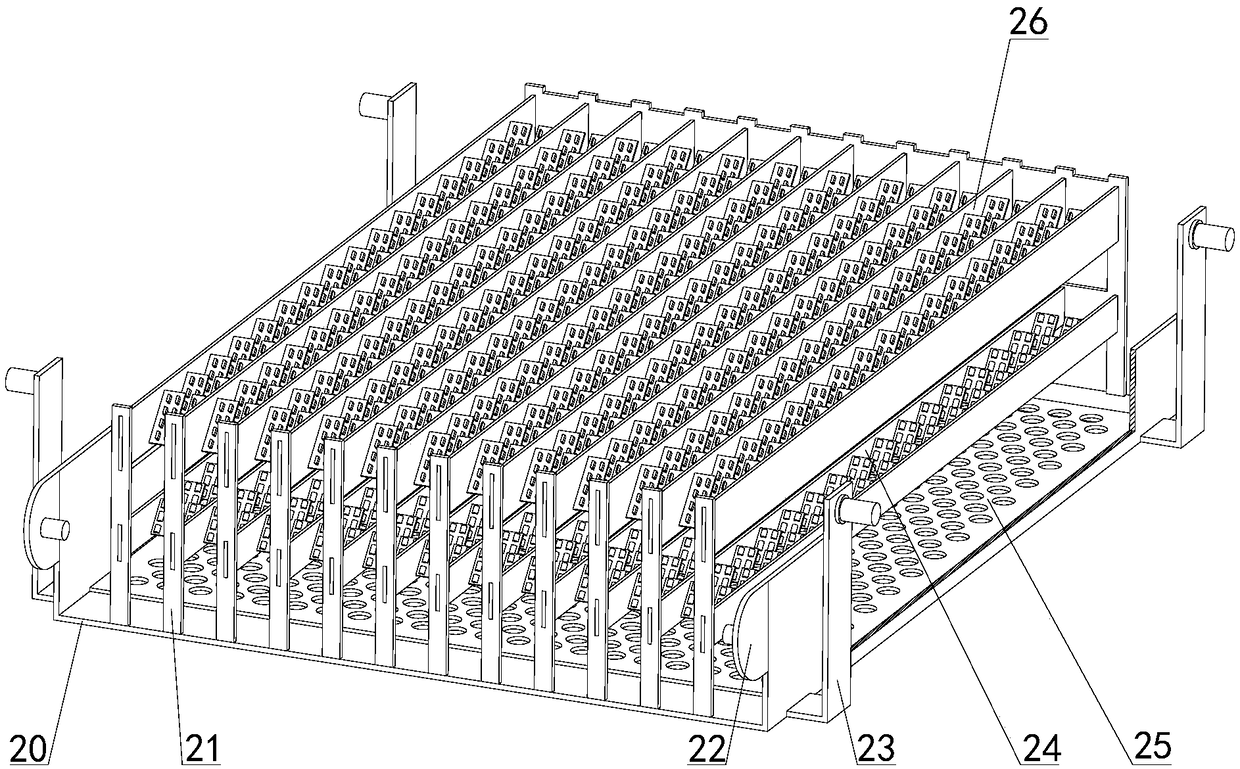

[0033] Such as figure 1 As shown, the present invention discloses a synchronous different-width nested kneading type vibrating screen for re-removing impurities, which is mainly composed of four parts: a frame 1, a transmission mechanism 2, a first synchronous vibration mechanism 3 and a second synchronous vibration mechanism 4 , wherein, the transmission mechanism 2 is installed in the front of the frame 1, the first synchronous vibration mechanism 3 is installed in the middle of the frame 1, the second synchronous vibration mechanism 4 is also installed in the middle of the frame 1, and the second The synchronous vibration mechanism 4 is nested above the first synchronous vibration mechanism 3 .

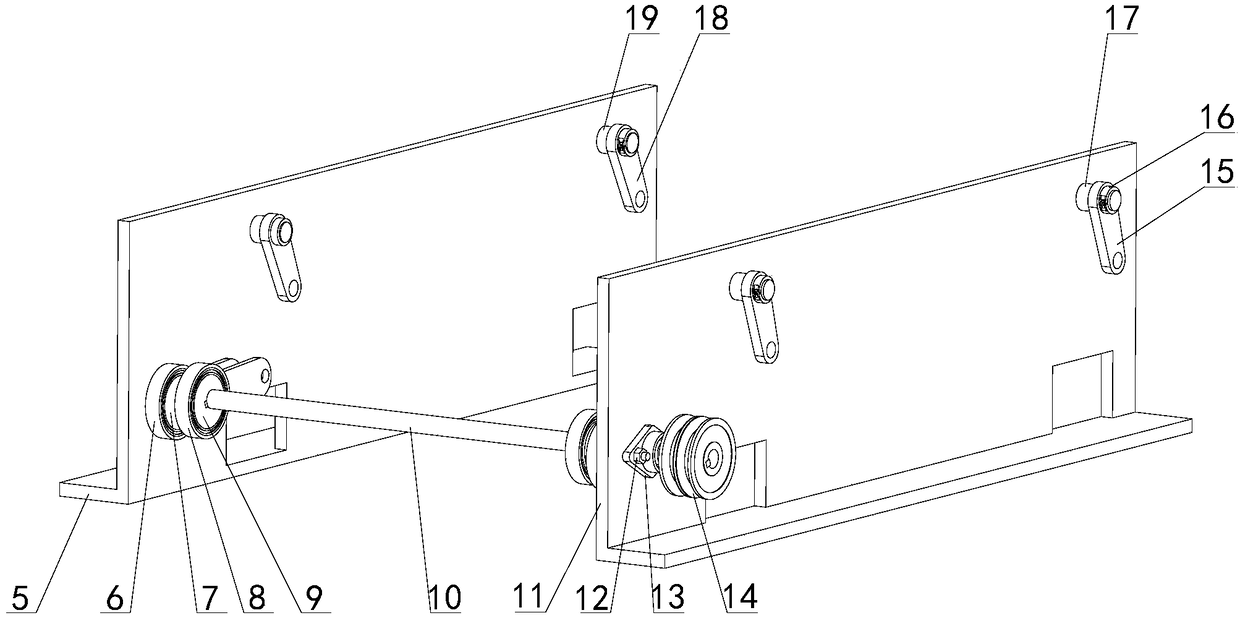

[0034] Such as figure 2 As shown, the frame 1 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com