All-wheel-drive non-amplitude vibrating screen mechanism

A technology of vibrating mechanism and vibrating screen, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of complex structure and high manufacturing cost, and achieve the effect of high cleaning efficiency, energy saving and large swing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the structure, characteristics and other purposes of the present invention, now in conjunction with the attached preferred embodiments are described in detail as follows:

[0016] Embodiments of the present invention are implemented as follows:

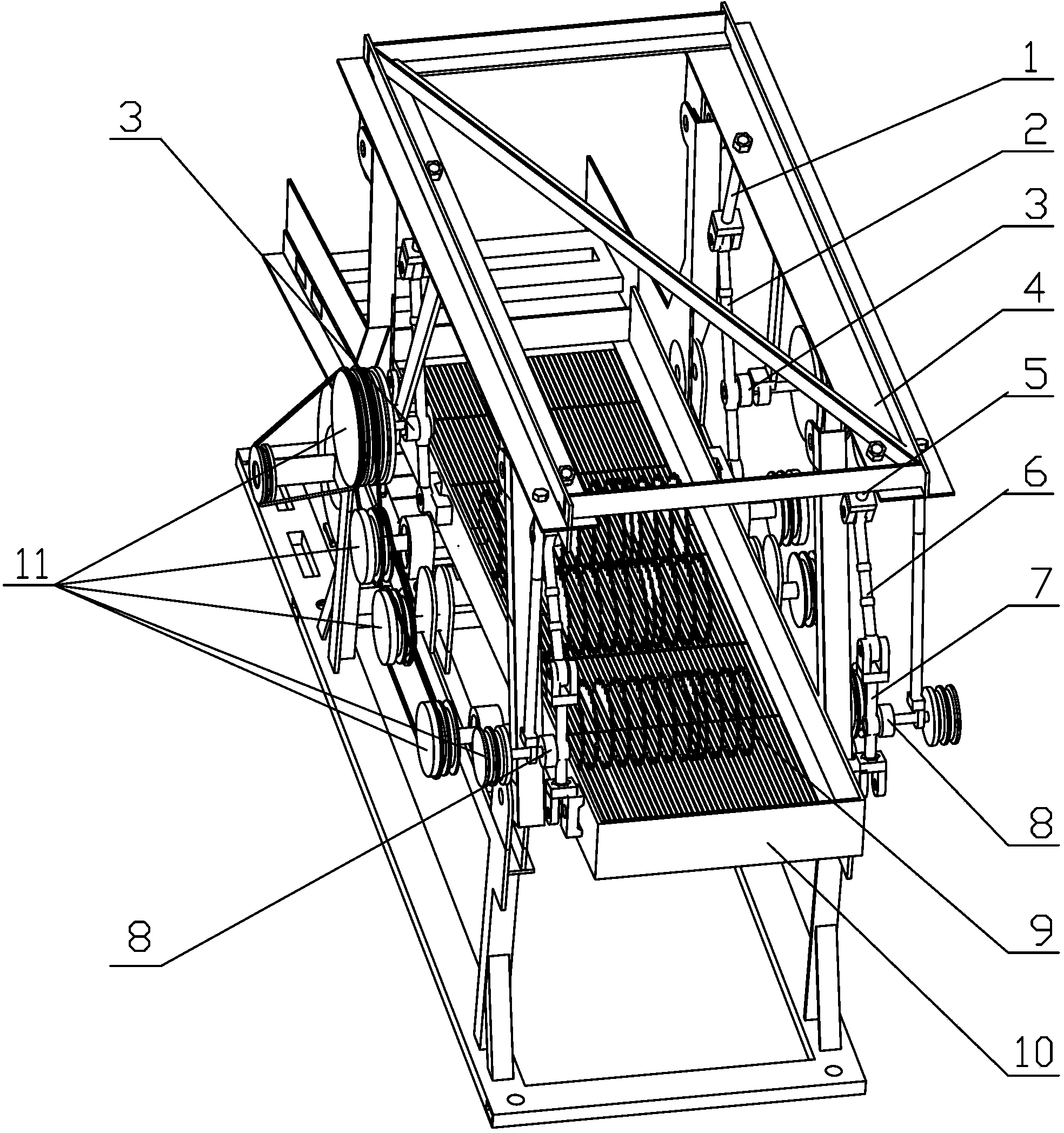

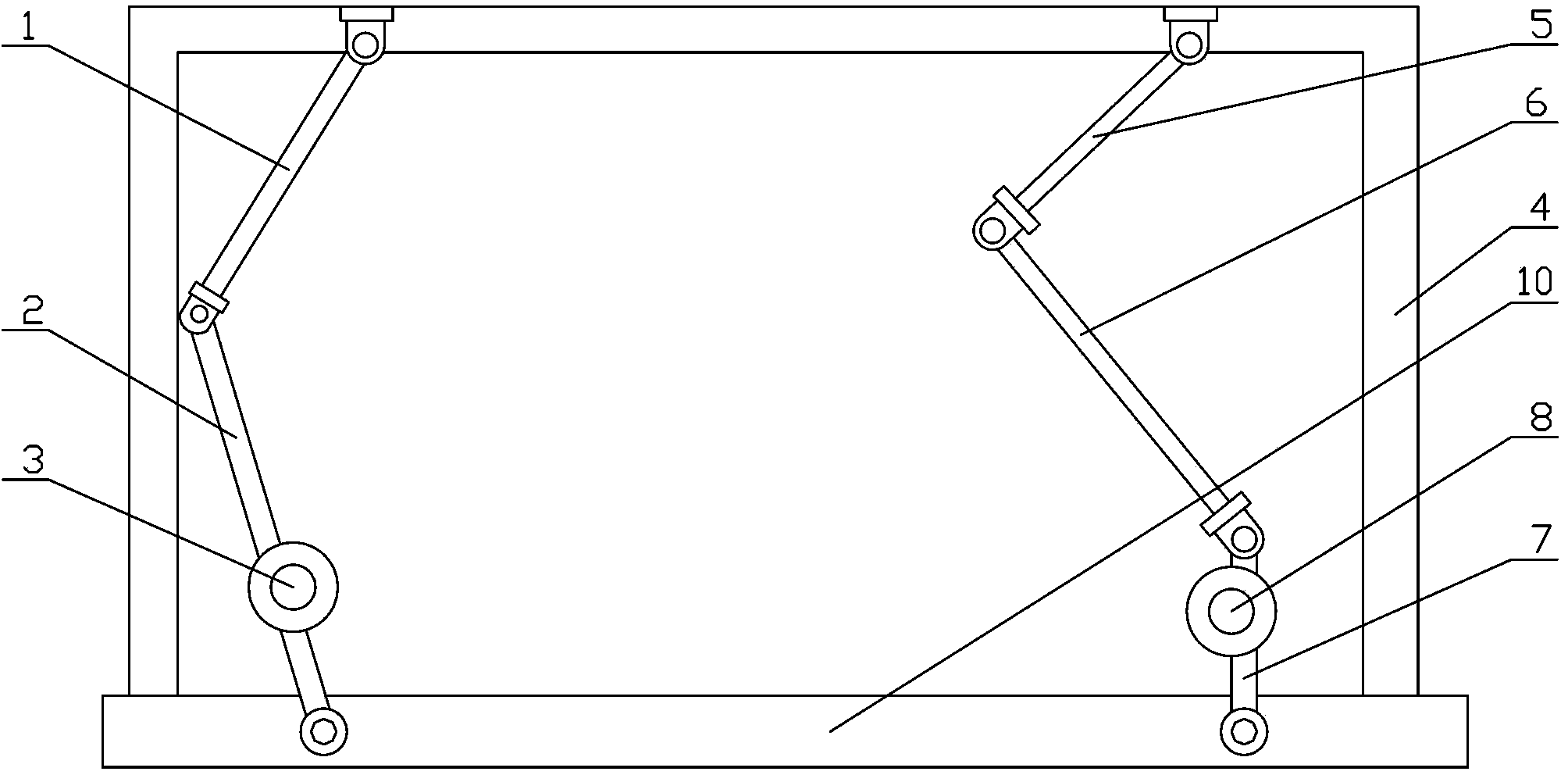

[0017] Such as figure 1 and figure 2 Shown: a four-wheel drive non-equal amplitude vibrating screen mechanism, including a vibrating screen 10 and a vibrating mechanism, the vibrating mechanism includes a pair of front eccentric wheels 8, a pair of rear eccentric wheels 3, a pair of front multi-stage connecting rods and a For the rear multi-stage connecting rod, the front eccentric wheel 8 and the rear eccentric wheel 3 are driven by the transmission mechanism 11, and the front eccentric wheel 8 and the rear eccentric wheel 3 are rotatably connected to the frame 4. The front eccentric wheel 8 The eccentricity is greater than the eccentricity of the rear eccentric wheel 3 and the transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com