Device and method for detecting welded body of grain cleaning sieve box

A detection device and detection method technology, applied in the direction of measuring devices, radio wave measurement systems, instruments, etc., can solve the problems of difficult quality assurance, complex structure of cleaning and screening welded body, high welding precision requirements, etc., to improve efficiency and Product quality, improving the level of agricultural mechanized manufacturing and testing, and improving the size pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to clearly explain the technical characteristics of the present invention so that those skilled in the art can clearly understand the structure, characteristics, usage and technical effects of the present invention, the scheme of the present invention will be described below through specific implementation methods and in conjunction with the accompanying drawings . However, the following descriptions are for illustrative purposes only, and are not intended to limit the present invention.

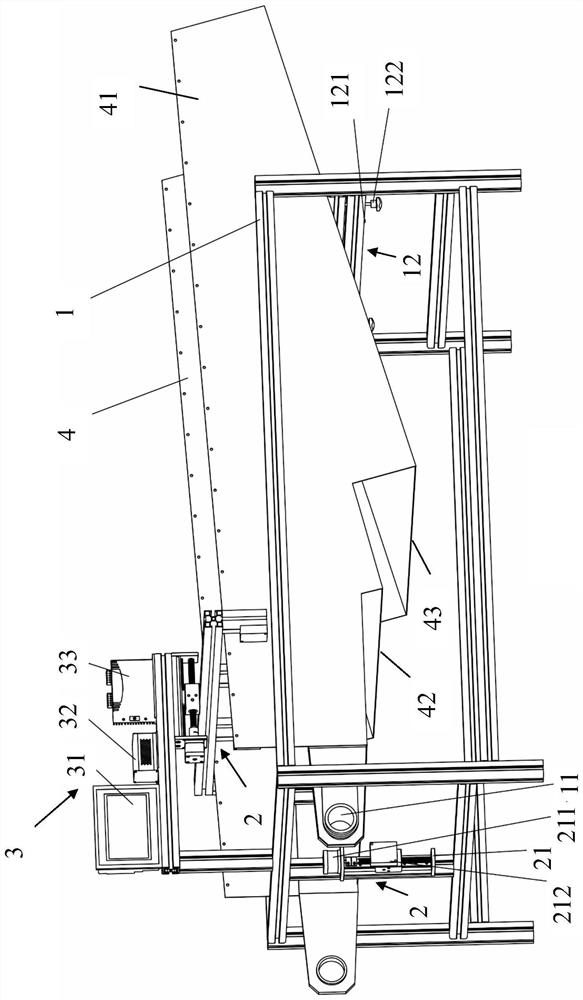

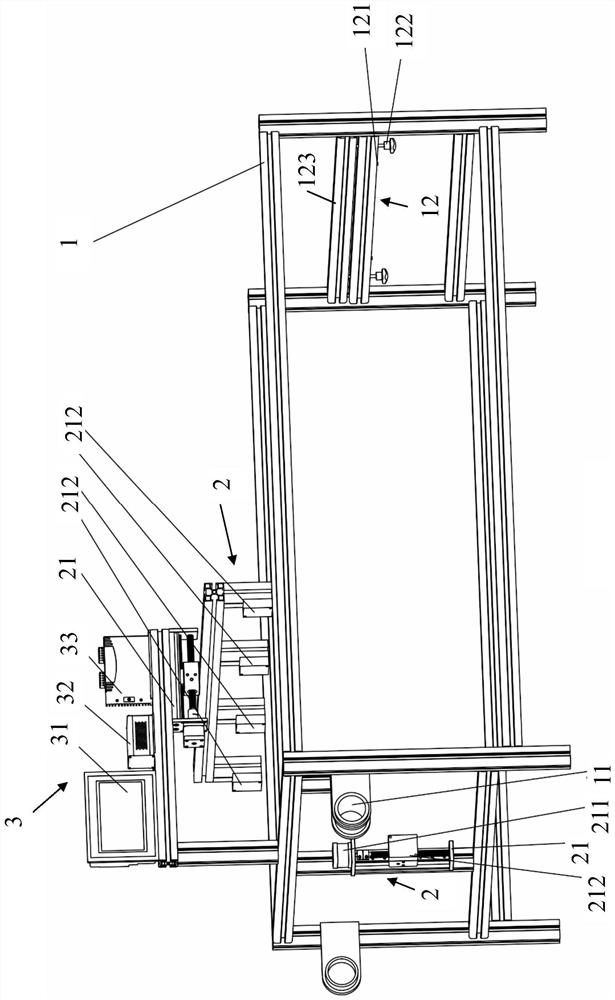

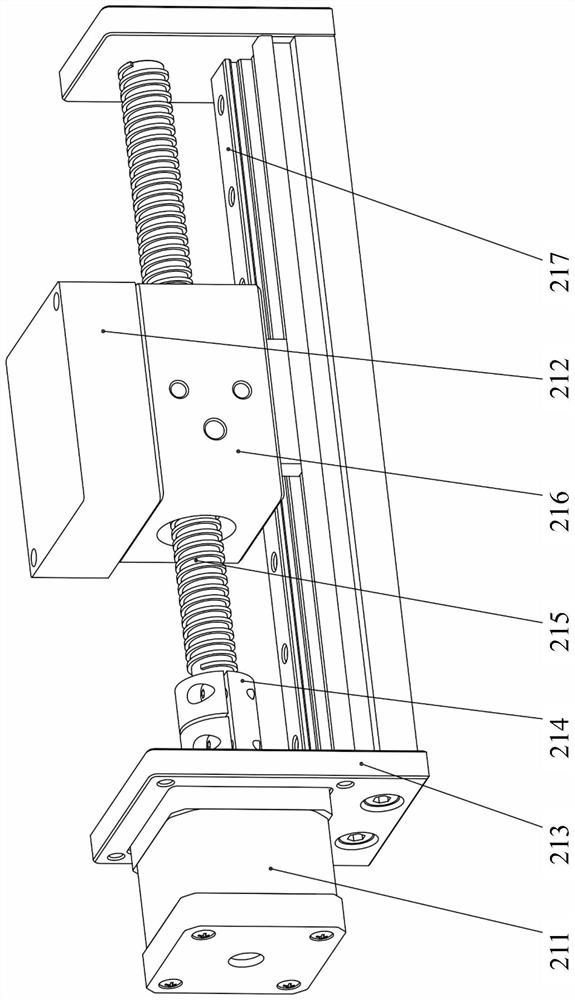

[0062] Please refer to Figure 1 to Figure 3 In order to detect the size of the grain cleaning sieve box welded body quickly and with high precision, the present invention provides a grain cleaning sieve box welded body detection device, which is used to detect a grain cleaning sieve box welded body 4, the The grain cleaning screen box welded detection device includes: a frame 1, a detection component 2 and a control display component 3.

[0063] The frame 1 includes a posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com