Multi-functional corn harvester intelligent control test platform based on CAN bus

A technology of corn harvester and CAN bus, which is applied in the field of corn harvester intelligent control test platform, can solve the problems of long test period and tedious and complicated work content, and achieve the effect of shortening the development period and ensuring real-time and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

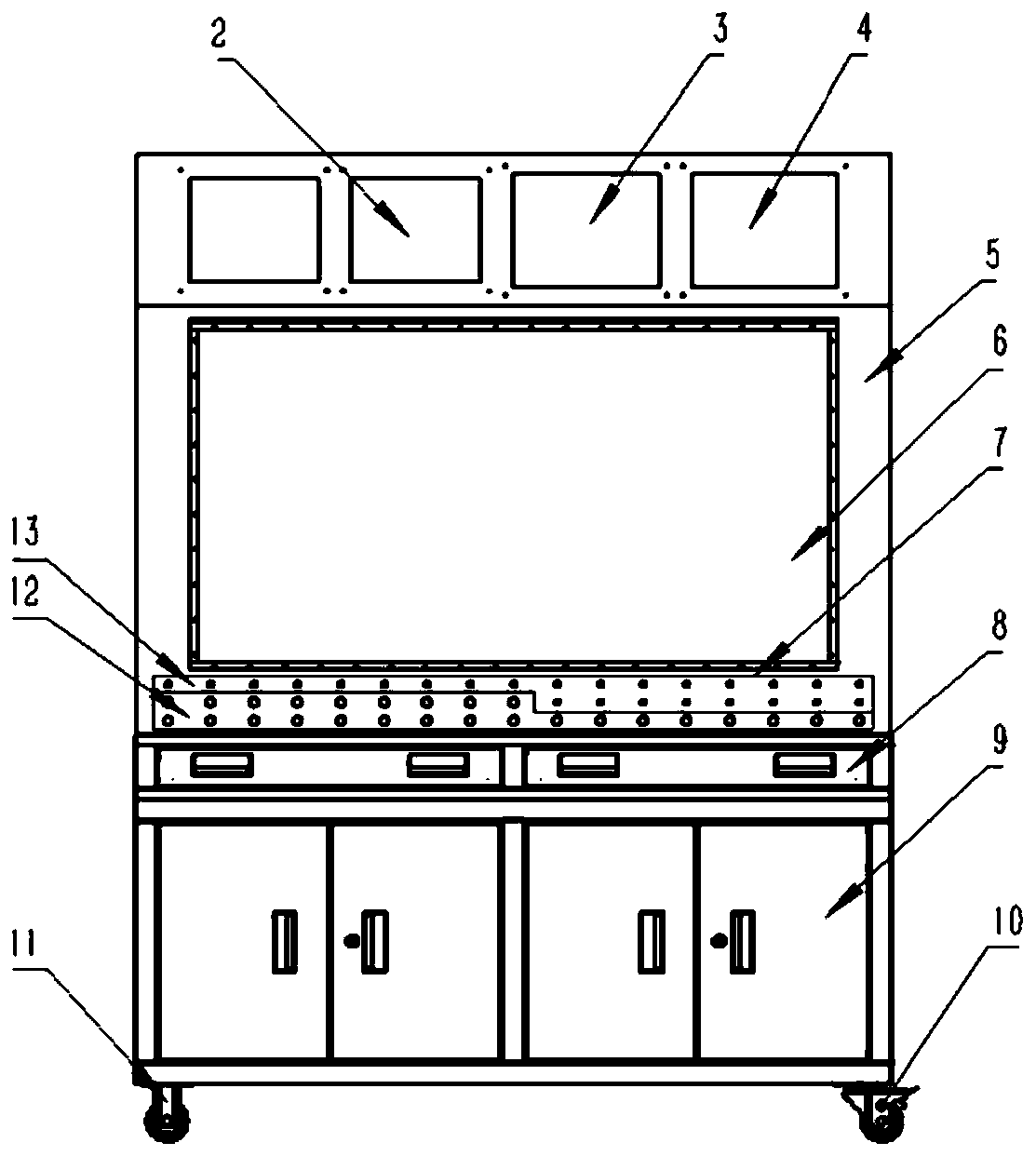

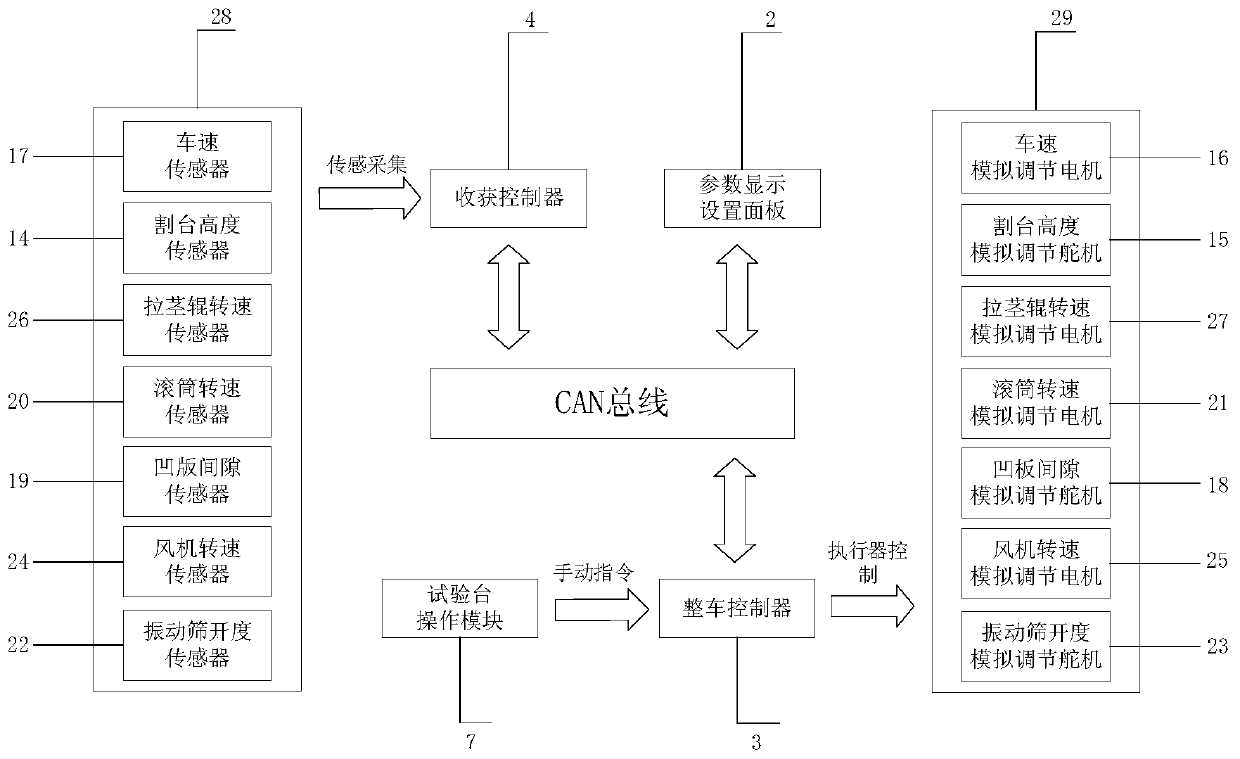

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

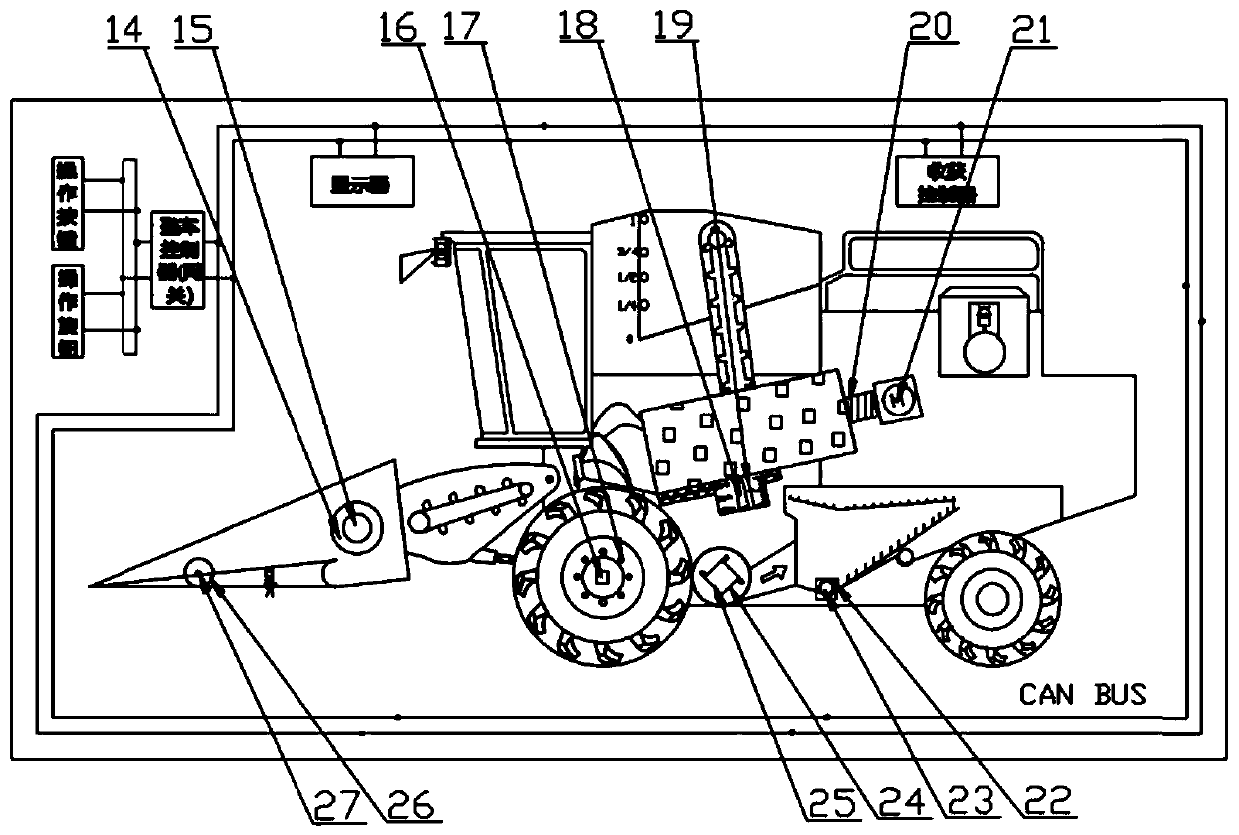

[0057] The model of the corn harvester simulated by the present invention is a vertical axial flow grain harvester, and the control module of the corn harvester control system includes: a walking control module, a header control module, a threshing control module and a cleaning control module.

[0058] The walking control module is responsible for the control of the walking speed of the whole vehicle. The engine transmits the power to the hydraulic pump, changes the opening of the walking proportional solenoid valve through the position of the control handle on the armrest box to control the speed of the walking hydraulic motor, and transmits the power to the wheels through the reducer. Control the whole vehicle to walk.

[0059] The header control module is responsible for taking off the ears of corn from the corn plant and sending them to the threshin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com