Adjustable cleaning system of soybean harvester

A harvester and cleaning technology, used in harvesters, agricultural machinery, agricultural machinery and implements, etc., can solve the problems of not considering the adjustment of the inclination of the vibrating screen, difficult to harvest soybeans, and inapplicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

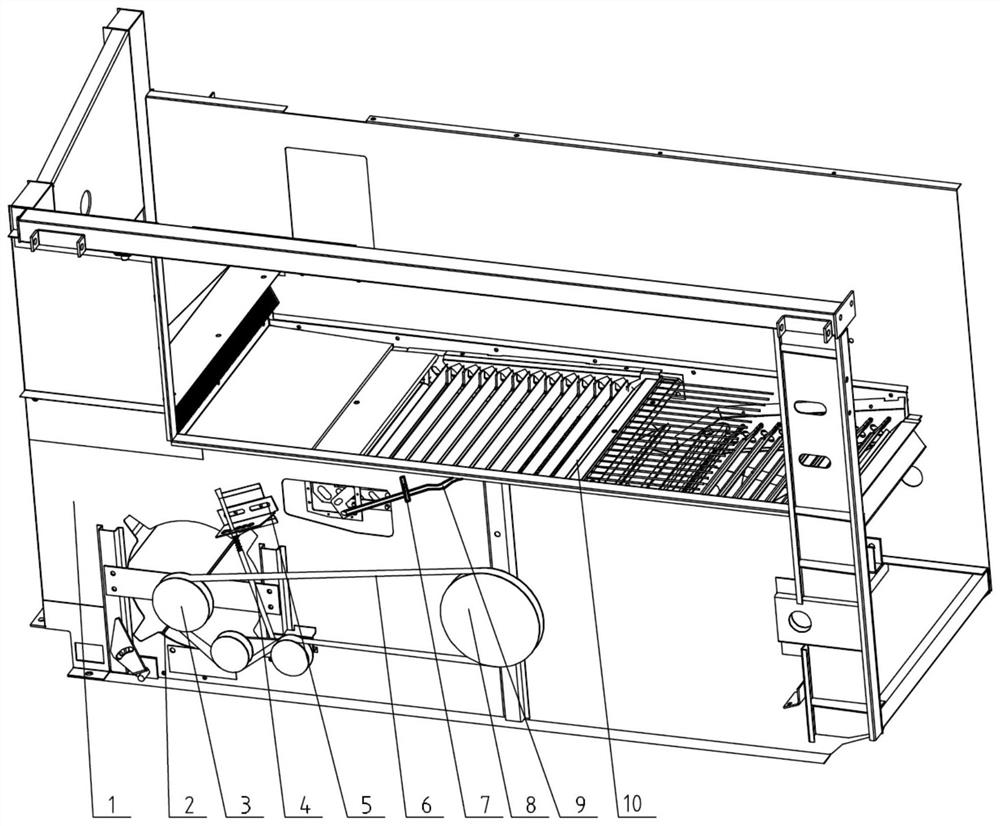

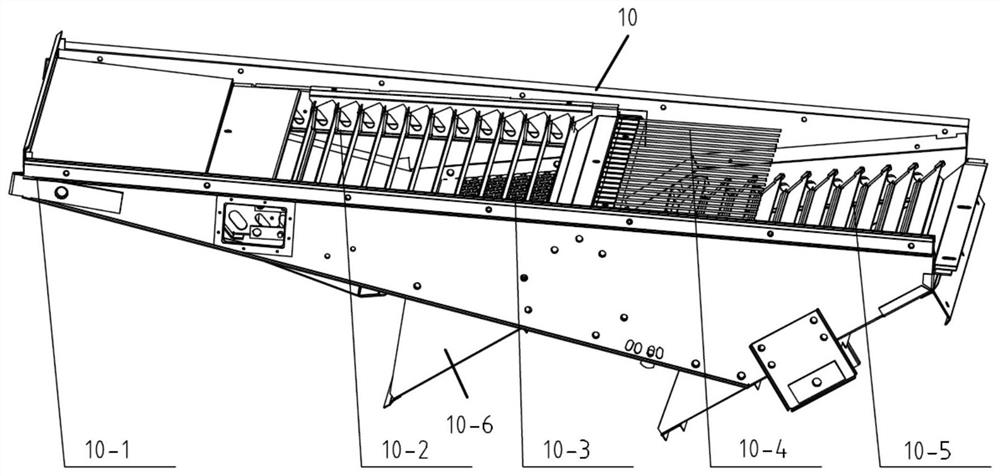

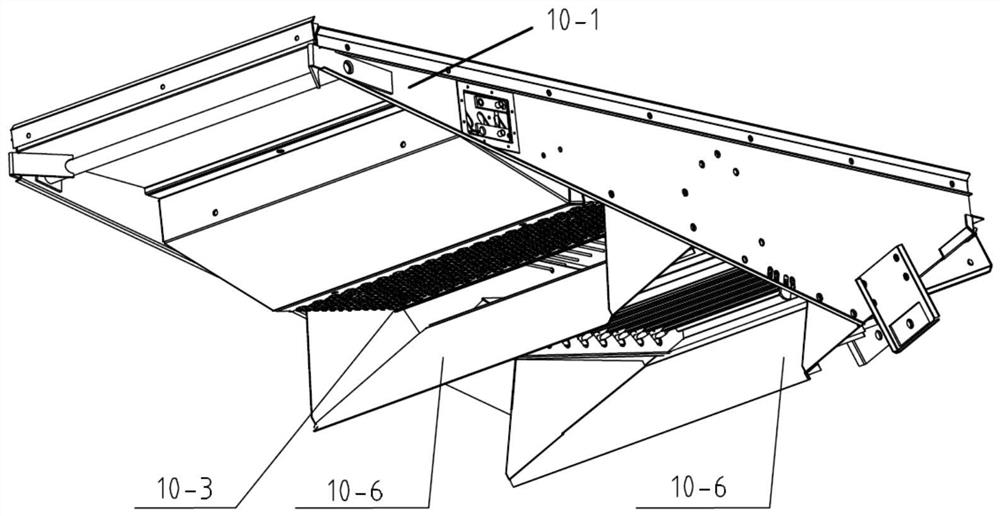

[0025] The adjustable cleaning system of the soybean harvester of this embodiment is applied to the soybean combine harvester, and its basic structure is as follows figure 1 As shown, a uniform flow fan 2 is installed below the feed end of the cleaning chamber frame 1, and a vibrating screen 10 is installed in the middle layer. The main shaft of the uniform flow fan 2 is equipped with a variable diameter pulley 3, and is connected with the driving pulley 8 through a transmission belt 6 with a tension adjustment mechanism 4.

[0026] Reducer pulley 3 such as Figure 5 As shown, a pair of reducer wheels 3-1 with opposite transmission cones are connected together by bolts and nuts 3-3 that act as axial limiters, and acted by elastic members 3-2 connected between them, with Axial approach trend, maximum spacing limited by bolt length. Tension adjustment mechanism 4 see Figure 5 and Image 6 , including the tensioning rod fixing frame 5 fixed on the cleaning room frame 1 and t...

Embodiment 2

[0034] The basic structure of the adjustable cleaning system of the soybean harvester of this embodiment is the same as that of the first embodiment, and the differences are as follows: Figure 10 As shown in the figure, the hinge pins A5.1 extending from the upper and lower ends of each screen piece A5 of the rear grid screen are firstly hinged with the corresponding hinge pin holes of the upper link A3.1 and the lower link A3.2 to form The rear screen assembly of the multi-parallel four-bar linkage mechanism is assembled into the frame enclosed by the front plate, the side plates on both sides and the rear plate of the rear grid screen. The structure of the front grid screen can be analogized. In this way, the assembly is more convenient, and the inclination adjustment is more stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com