Negative pressure type grain secondary winnowing device

A negative pressure, winnowing technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of poor cleaning effect, no debris blown out, and impurities blown by the wind Flying and other problems, to reduce environmental pollution, improve cleanliness, and reduce cleaning losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

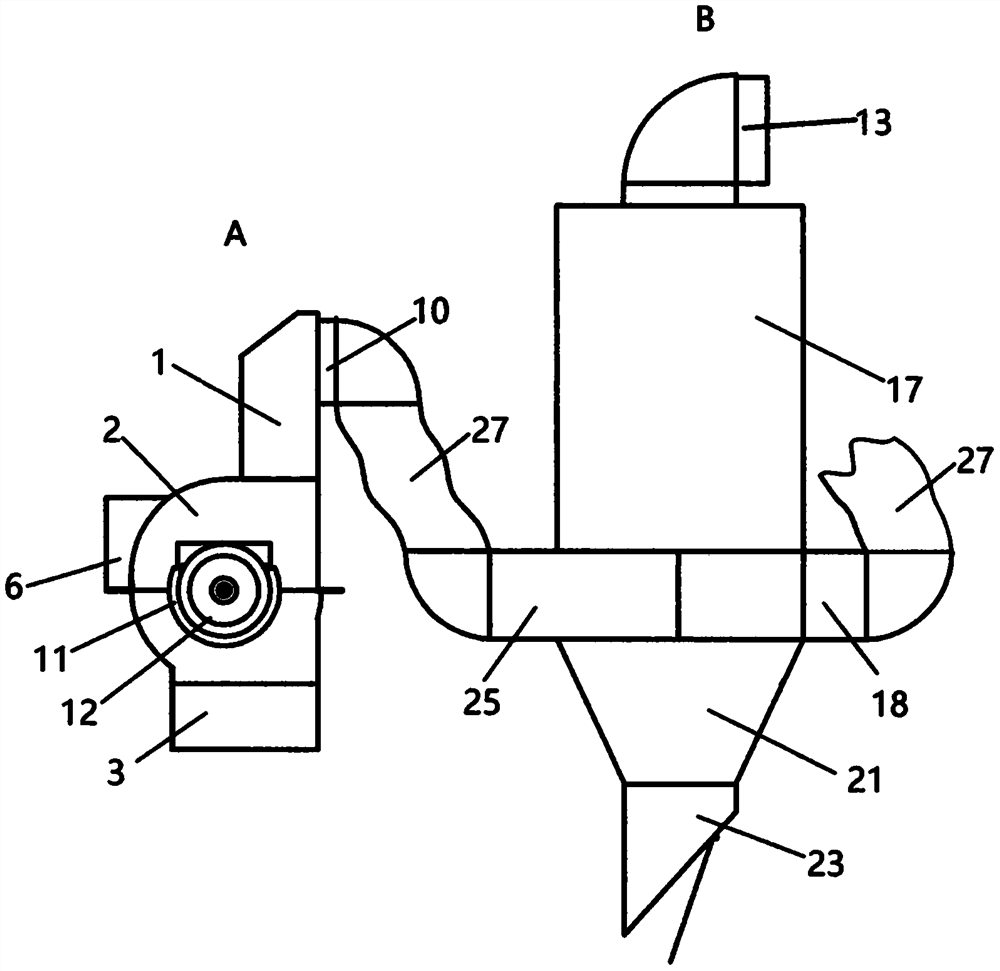

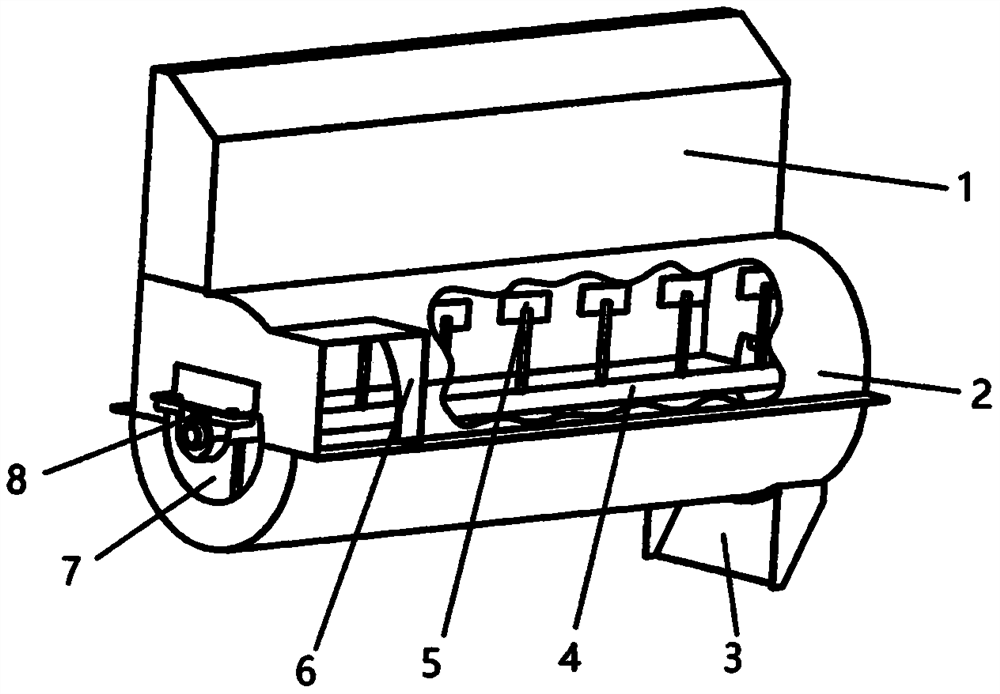

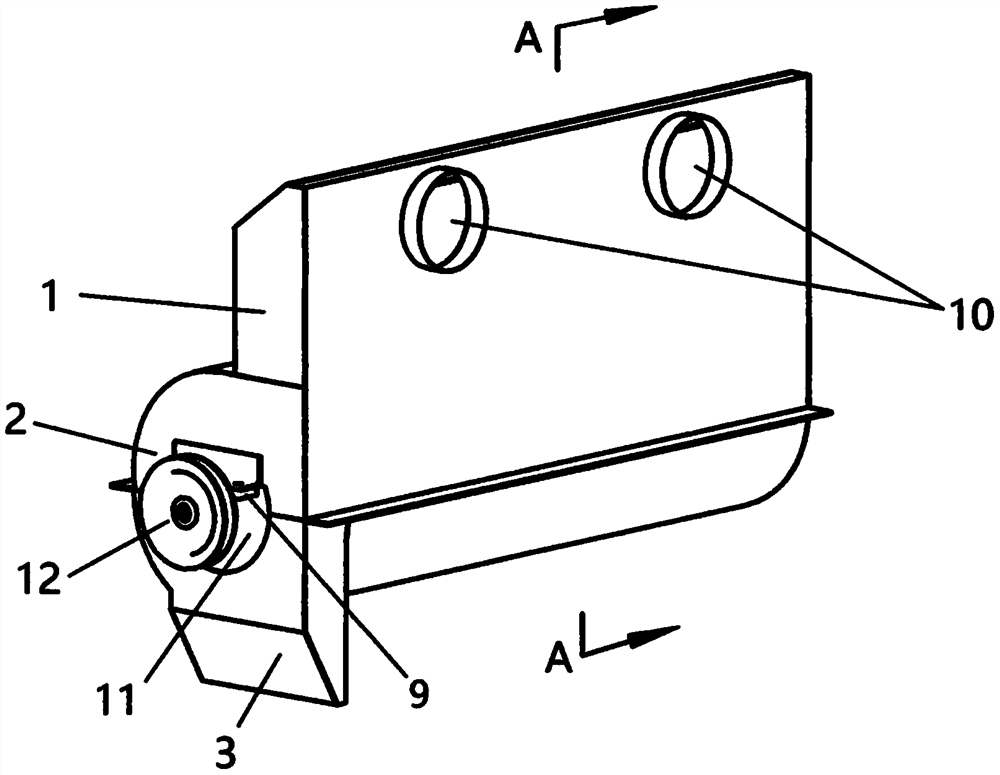

[0017] Such as Figure 1-6 What you see: A negative-pressure two-stage grain winnowing device, including a first winnowing part A, a second winnowing part B, and an air pipe elbow for the first winnowing part A and the second winnowing part B 27 connection; it is characterized in that, the first winnowing part A comprises winnowing housing 2, raising valley shaft 4, raising grain sheet 5, and the upper part of described winnowing housing 2 is provided with air channel 1, and air channel 1 The interior communicates with the inside of the winnowing shell 2, the upper part of the air duct 1 is provided with an air suction port A10, the left end of the winnowing shell 2 is provided with a left air inlet A7 and a discharge port 3, and the right end is provided with a right air inlet A11 and a feed mouth 6, a number of valley-lifting piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com