Cleaning system and combined grain harvester adopting same

A combine harvester and cleaning technology, which is applied in the field of agricultural machinery, can solve the problems of cleaning loss and easy clogging of the cone section, and achieve the effects of reducing the diameter of the cylinder, improving the cleaning capacity, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

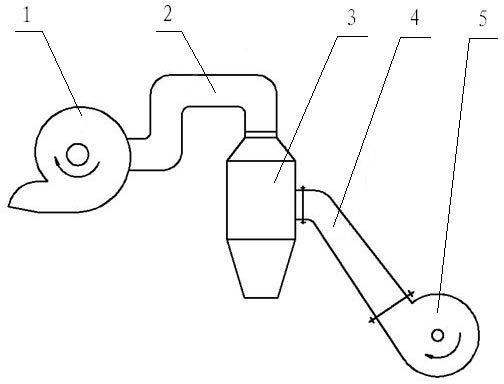

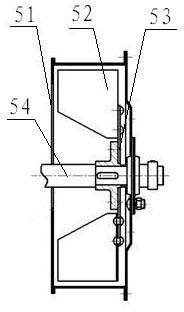

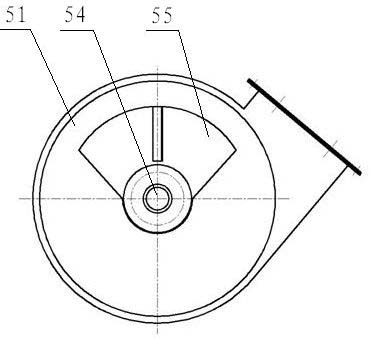

[0023] Embodiments of the cleaning system of the present invention: as Figure 1-6 As shown, it includes a cyclone separation drum 3, a grain lifting device 5, a valley lifting pipeline 4, a miscellaneous suction blower 1 and a miscellaneous suction pipeline 2. Cyclone separation cylinder 3 comprises cylinder body 31, and cylinder body 31 is the open structure of upper and lower ends, and the upper section of cylinder body 31 is the cone section with upper small and lower section, the middle section is cylinder section and the lower section is the cone section with upper section and lower section, The cylinder section of the cylinder 31 is communicated with a separation pipe 32 extending along its radial direction, the separation pipe 32 is a square pipe, the side wall of the separation pipe 32 away from the axis of the cylinder 31 and the cylinder wall protruding from the cylinder section, Moreover, the side wall of the separation pipe 32 away from the axis of the cylinder 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com