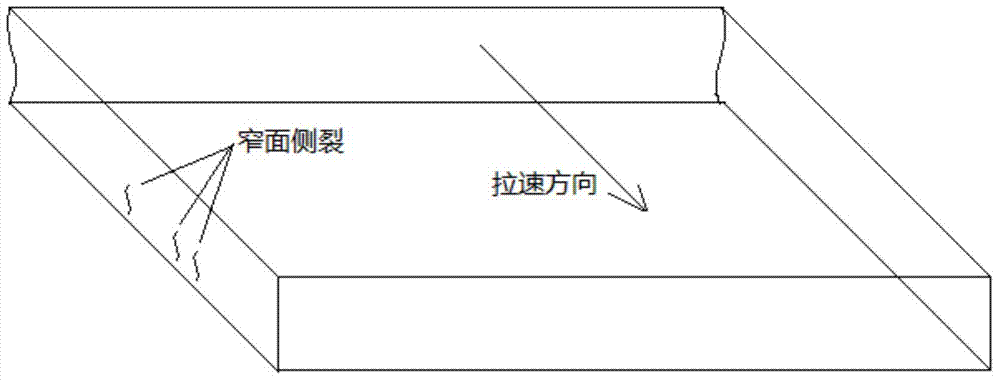

Comprehensive control method of medium-carbon niobium-containing steel narrow face lateral fissure of thick plate blank

A comprehensive control and thick slab technology, applied in the field of steelmaking-continuous casting, can solve problems such as side cracks on narrow surfaces, achieve the effects of reducing side cracks, smooth continuous casting production process, and increasing high-temperature thermoplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A steel plant adopted this process when casting 300mm×2000mm medium-carbon and niobium-containing continuous casting slabs on a continuous casting machine. 2 -26.9%, Fe 2 o 3 -0.5%, MgO-1.3%, Al 2 o 3 -4.3%, K 2 O+Na 2 O-8%, F-6.9%, Li 2 O-1.87%, BaS-1.5%, volatile matter 5.73%, melting point 1130°C, viscosity 0.118PaS, density 0.83g / ml; immersion depth is 165mm when casting 1-5 furnaces, 155mm when casting 6-10 furnaces, 11- It is 145mm for 15 furnaces, and 135mm for 16-19 furnaces; the taper coefficient is 1.0%, the water volume of the foot roll is 149.5L / min, the casting process is stable, the surface quality of the slab is good, and the narrow side cracks are well improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com