Method and device for dynamically maintaining conicity of narrow face of slab crystallizer on line

A crystallizer and taper technology, which is applied in the field of online dynamic maintenance of the taper of the narrow side of the slab mold, can solve the problem that the narrow side taper of the slab continuous casting mold can not be fundamentally solved, and the narrow side taper can be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

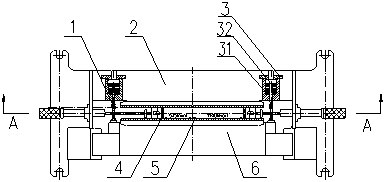

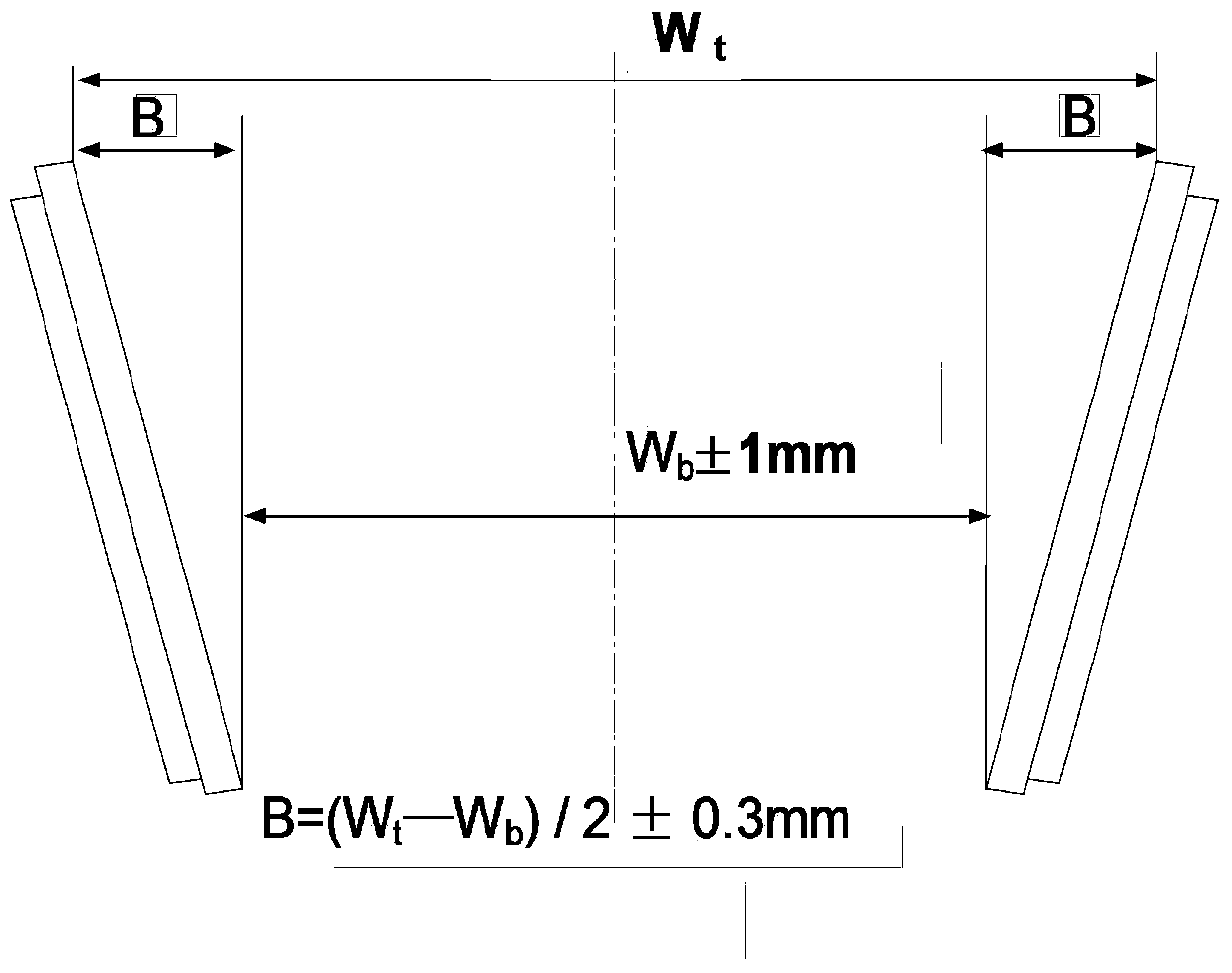

[0020] figure 2 Description of marks: clamping rod 1, outer arc water tank 2, clamping oil cylinder 3, disc spring 31, piston rod 32, narrow side copper plate 4, wide surface copper plate 5, inner arc water tank 6.

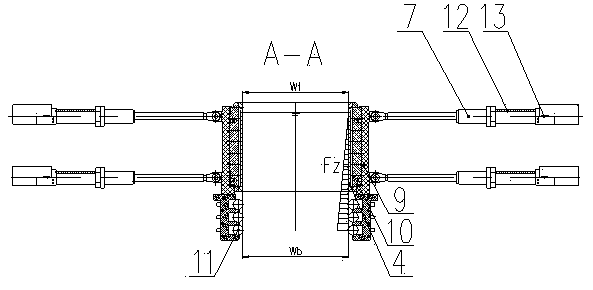

[0021] image 3 Description of markings: narrow side width adjustment hydraulic cylinder 7, narrow side moving plate 9, narrow side back plate 10, narrow side foot roller 11, displacement sensor 12, proportional servo valve 13.

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] as attached figure 2 As shown, the device for dynamically maintaining the taper of the narrow side of the slab crystallizer on-line includes a narrowing mechanism and a wide-side clamping mechanism. Copper plate 4, wide face copper plate 5 and inner arc water tank 6 form, and clamping oil cylinder 3 contains disc spring 31, piston rod 32. One end of the clamping rod 1 is pressed on the outer wall of the inner arc wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com