Narrow-face copper plate for asymmetric slab continuous casting chamfering crystallizer

A technology of chamfering crystallizers and narrow-faced copper plates, which is applied in the field of steelmaking-continuous casting, can solve problems such as internal and external arcs without consideration, and achieve the effects of increasing temperature, reducing incidence, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

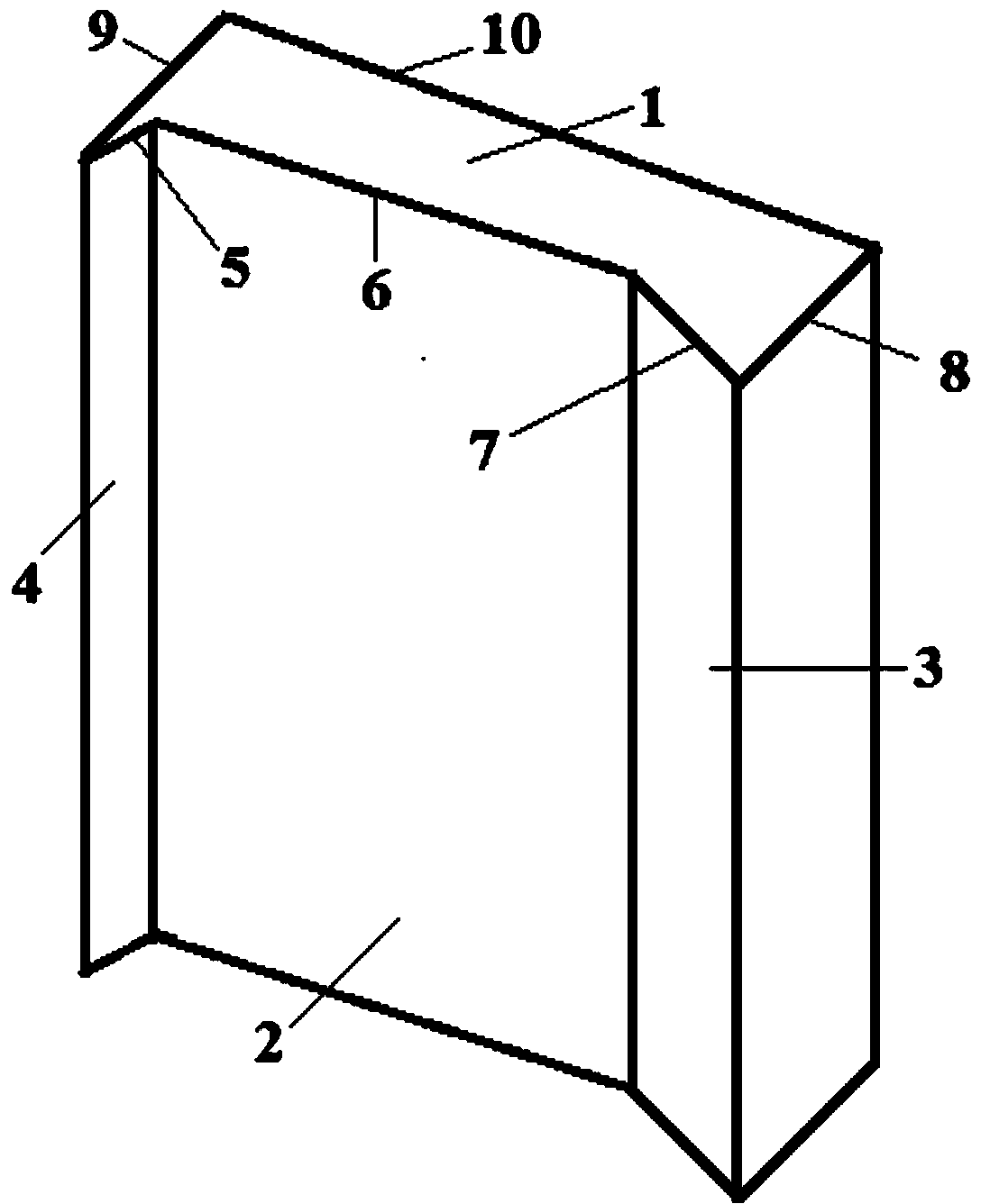

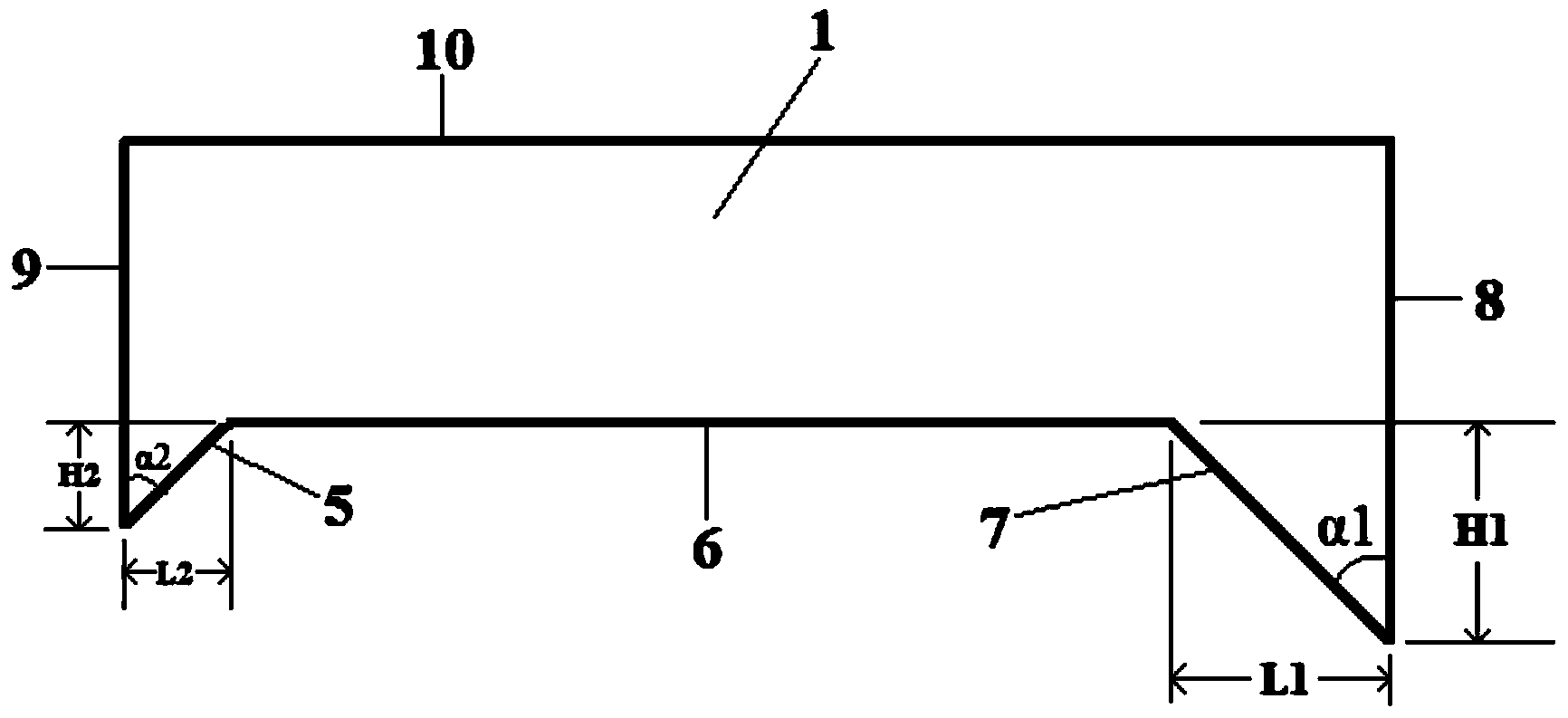

[0030]When casting a slab of 280×2000mm, the narrow-sided copper plate adopts the design of large inner arc chamfer and small outer arc chamfer. The size of L1 is 40mm, and the size of H1 is 40mm. The upper edge of the large inner arc chamfer and inner arc copper plate The angle α1 between the upper edges 8 is 45°. The size of L2 is 10mm, the size of H2 is 10mm, and the angle α2 between the upper edge 5 of the small-sized outer arc chamfer and the edge 9 of the outer arc copper plate is 45°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com