Narrow-face copper plate for chamfer crystallizer

A technology for chamfering a mold and a narrow-faced copper plate, which is applied to the field of components on the mold, can solve the problems of small arc chamfering, limited temperature increase at the corner of the billet, and multiple longitudinal cracks in the billet, so as to compensate for shrinkage. , Enhance the effect of solidification uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

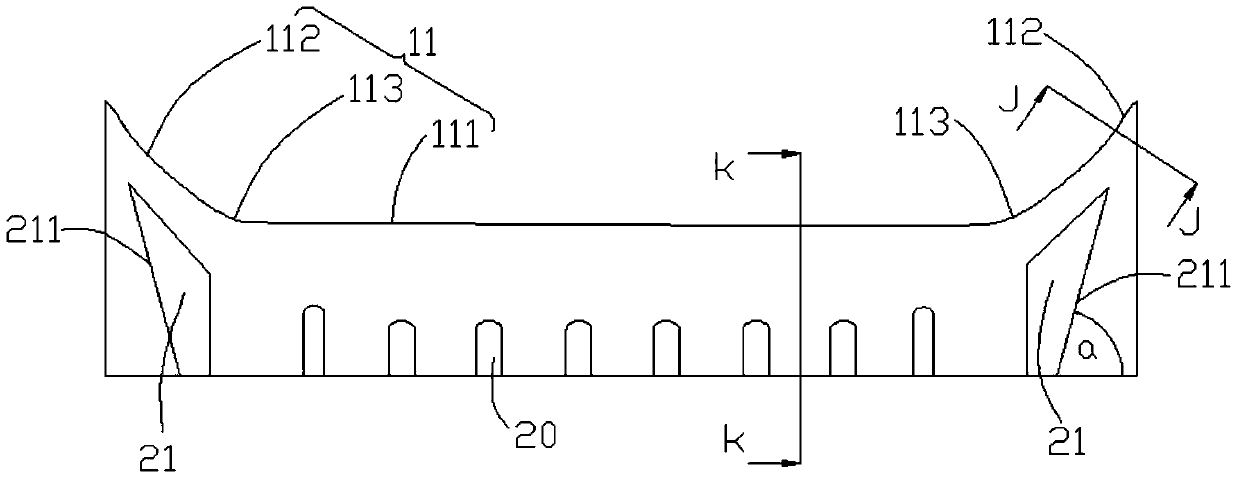

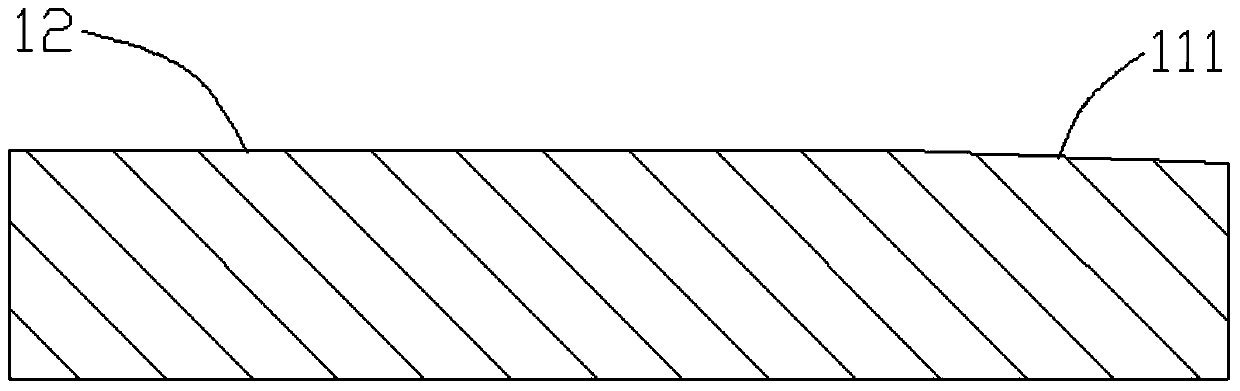

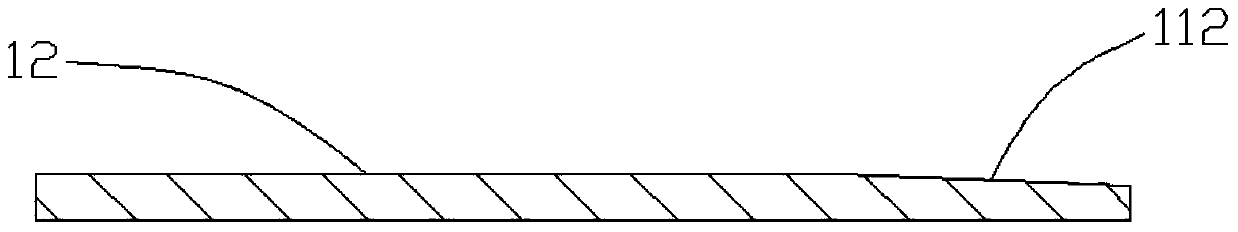

[0025] figure 1 It is a top view of the chamfering crystallizer narrow surface copper plate in a preferred embodiment of the present application. Such as figure 1 As shown, the narrow copper plate 100 of the chamfering crystallizer includes a working surface 10, while referring to figure 2 with image 3 , the working surface 10 is a concave curved surface, and the working surface 10 includes a first part 11 and a second part 12 . Wherein, the first part 11 is the part on the working face 10 within the range of 200 mm to 400 mm from the upper mouth of the crystallizer, and the second part 12 is the part on the working face 10 that is outside the range of 200 mm to 400 mm from the upper mouth of the crystallizer. part.

[0026] The first part 11 includes a first curved area 111 , two second curved areas 112 , and two transitional curved areas 113 .

[0027] The first curved area 111 is a quadratic parabolic area. Preferably, in this embodiment, the quadratic parabola equa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com