I-shaped piling wall type cement pavement crack repairing structure and repairing method

A technology for repairing cement pavement and cracks, applied in road repair, roads, roads, etc., can solve the problems of unsatisfactory renovation effect, difficult traffic maintenance, surface peeling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

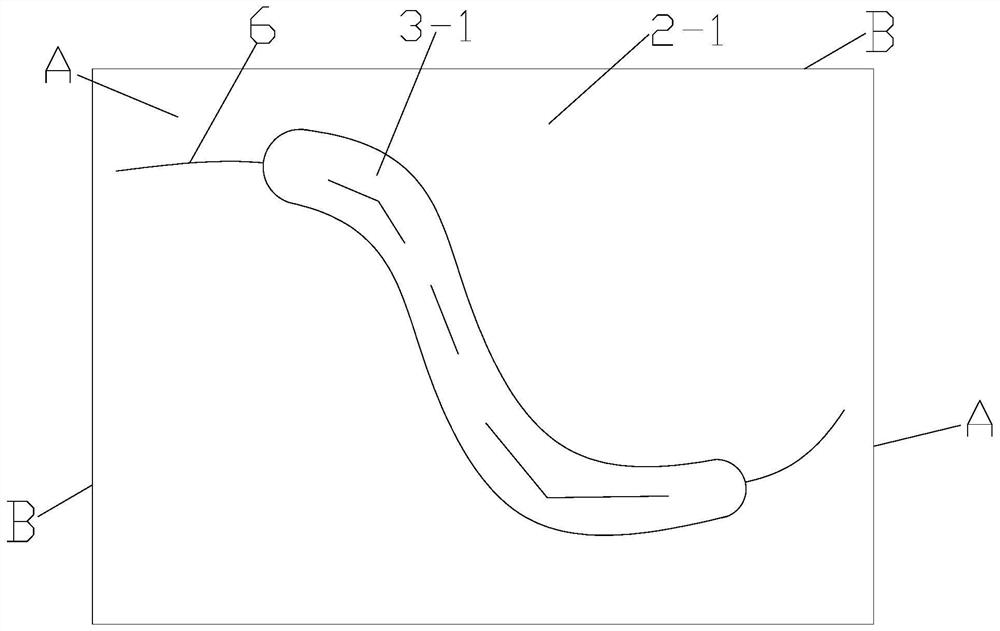

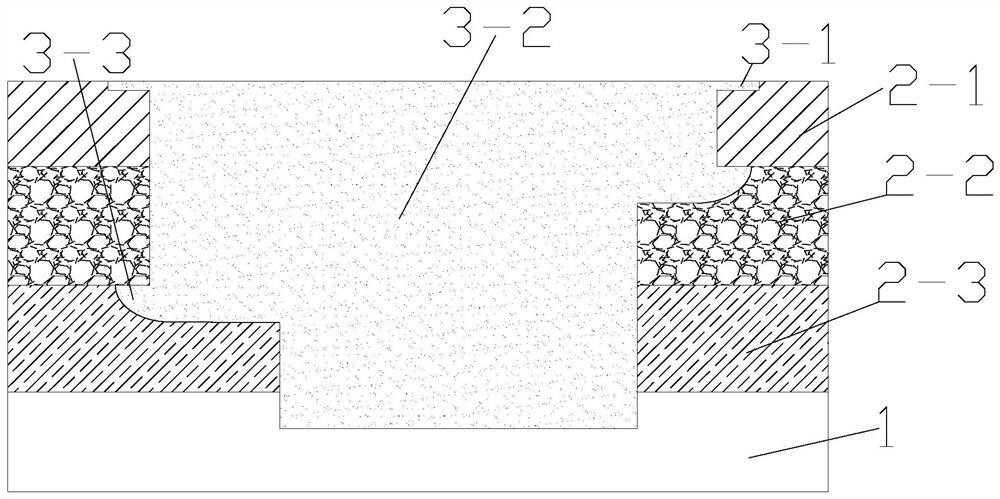

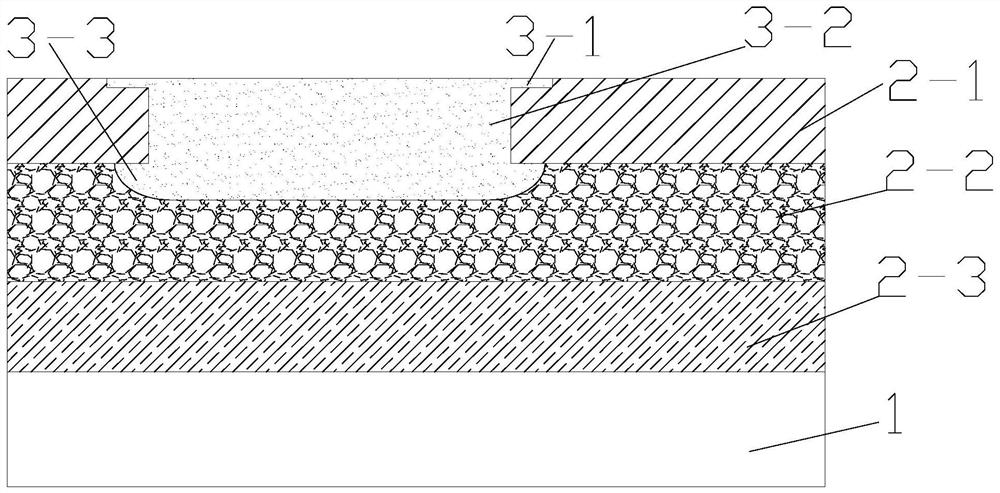

[0038] Such as figure 1 with figure 2 As shown, the present invention includes an I-shaped pile wall arranged along the length extension direction of the crack 6 and used for continuously repairing the layer to be repaired on the road surface. , the lower flange splint 3-3 located at the bottom of the web pile wall 3-2 and integrally connected with the web pile wall 3-2, and the fixed part of the web pile wall 3-2 and integrated with the web pile wall 3-2 The connected upper flange splint 3-1, the web pile wall 3-2 intersect with the crack 6, the lower flange splint 3-3 is located at the bottom of the crack 6, the upper surface of the upper flange splint 3-1 meets the cement pavement panel layer 2 The upper surface of -1 is flush, and the pavement to be repaired is the cement pavement panel layer 2-1, the cement pavement base layer 2-2 or the cement pavement subbase layer 2-3.

[0039] It should be noted that the continuous and comprehensive repair of the entire crack on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com