A valve connection device for wind tunnel experiments

A connection device and wind tunnel experiment technology, which is applied to sleeve/socket connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as high temperature and high pressure gas leakage, flange seal failure, pipeline deformation, etc., to eliminate Effect of bending moment, avoiding seal failure, and preventing axial deflection moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

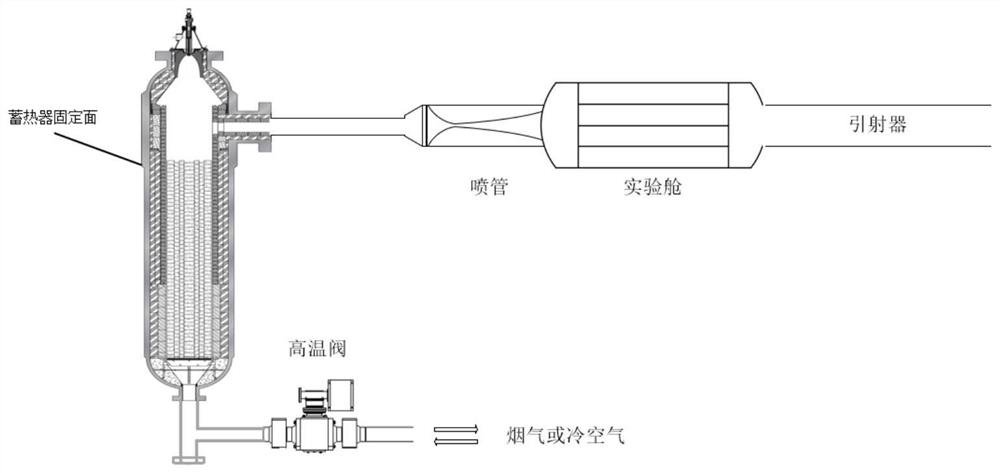

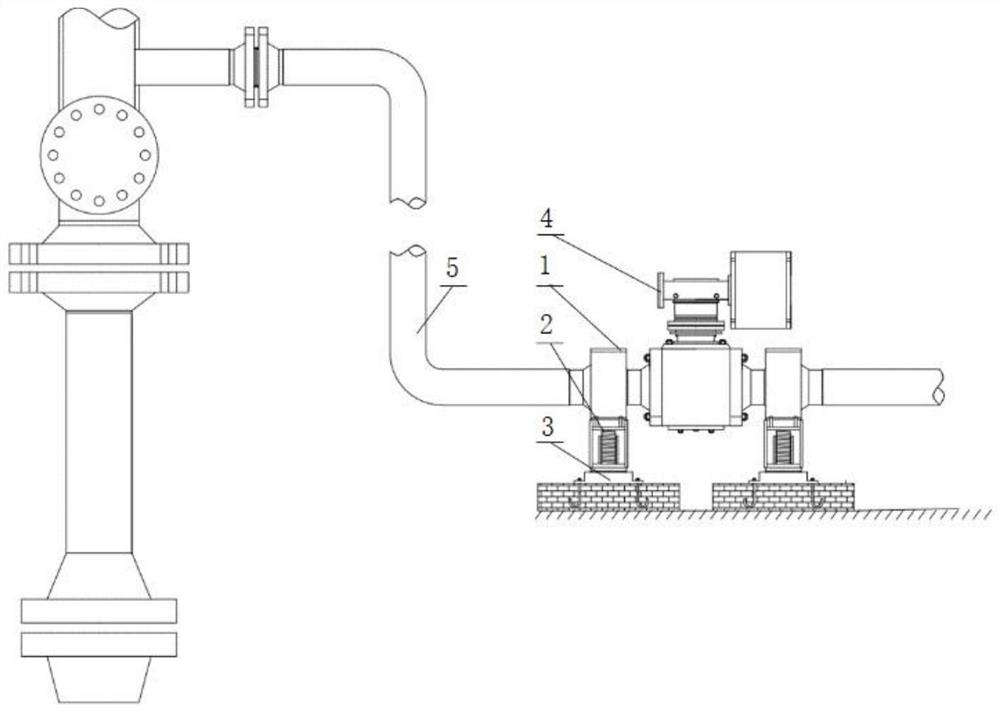

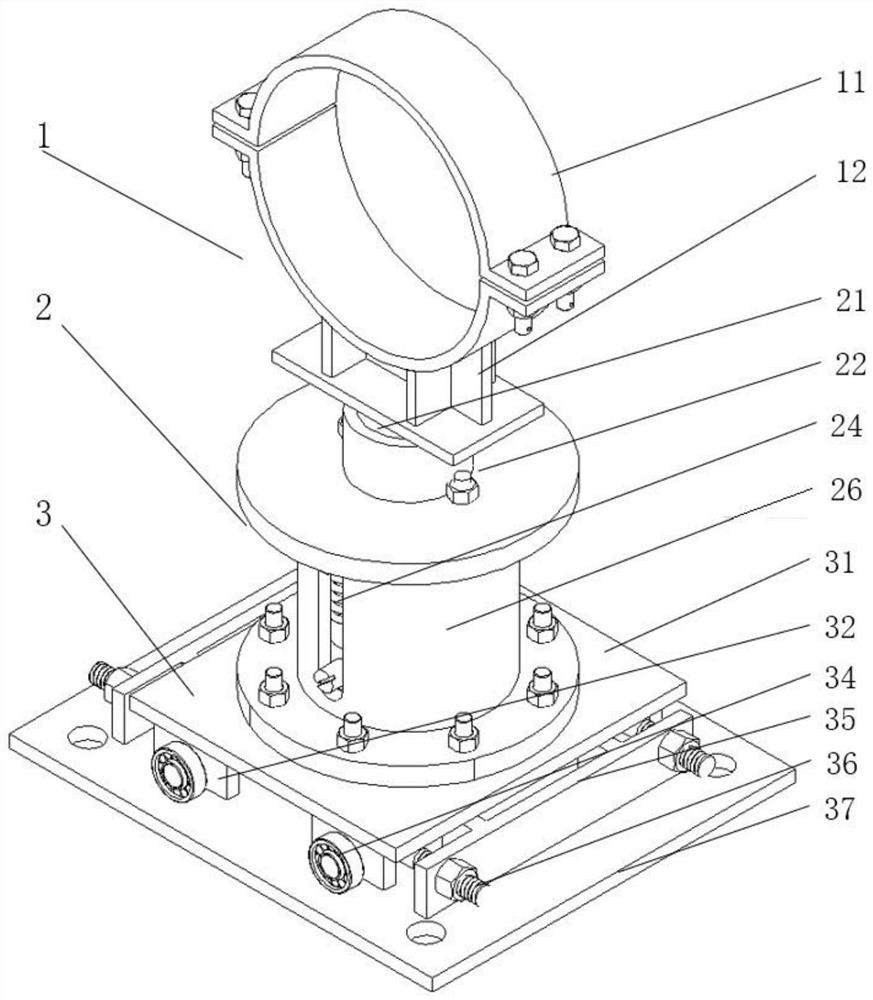

[0038] Such as figure 2 As shown, a valve connection device for wind tunnel experiments is provided with a lifting device, and the lifting device includes a flange clamp 1, an elastic support mechanism 2 and a sliding base 3, and the lower end of the sliding base 3 is fixed on the ground. More specifically, the lower end of the base 3 is fixed on the ground through anchor bolts, the upper end of the base is connected to the elastic support mechanism 2, and the top end of the elastic support mechanism is set as a flange clamp 1, through which a set of flange clamps The high temperature valve 4 is flange-locked on the connecting pipe 5 of the high temperature valve 4 .

[0039] The flange clamp 1 is configured as a ring structure, and its inner diameter is consistent with the diameter of the external flange of the high temperature valve 4 . More specifically, the flange clamp 1 is set as a circular structure with an inner diameter of 245 mm, and the circular structure is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com