Construction method of shear resistance and strengthening of concrete box beams based on corrugated steel webs

A technology of corrugated steel webs and concrete box girders, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of affecting the appearance of the bridge, increasing the self-weight of the bridge, and the limited improvement of the shear bearing capacity, etc., to achieve structural and structural The effect of clear stress, prevention of concrete cracks, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

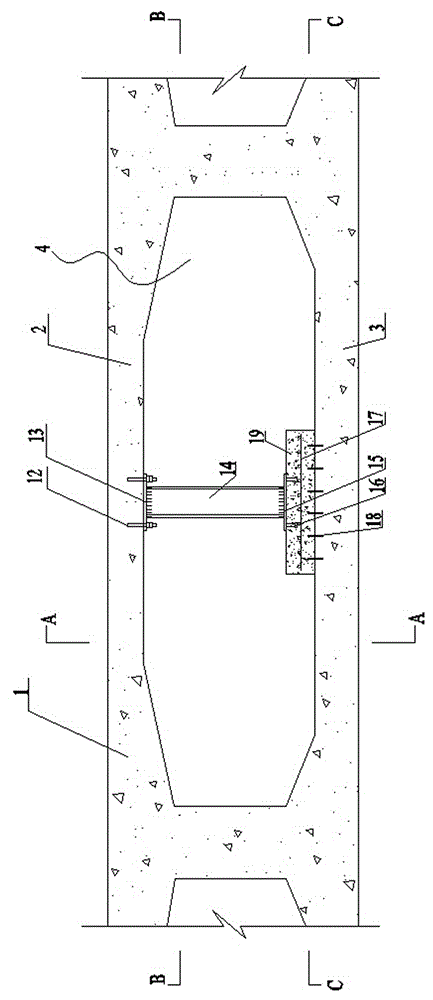

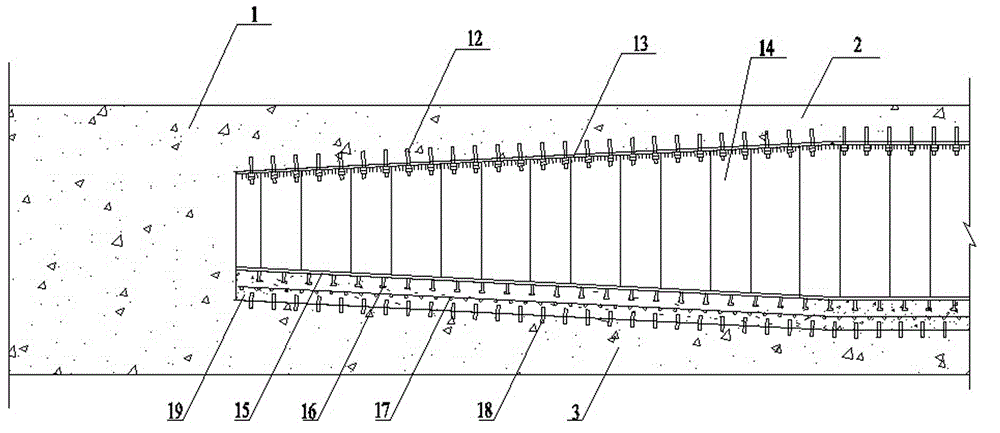

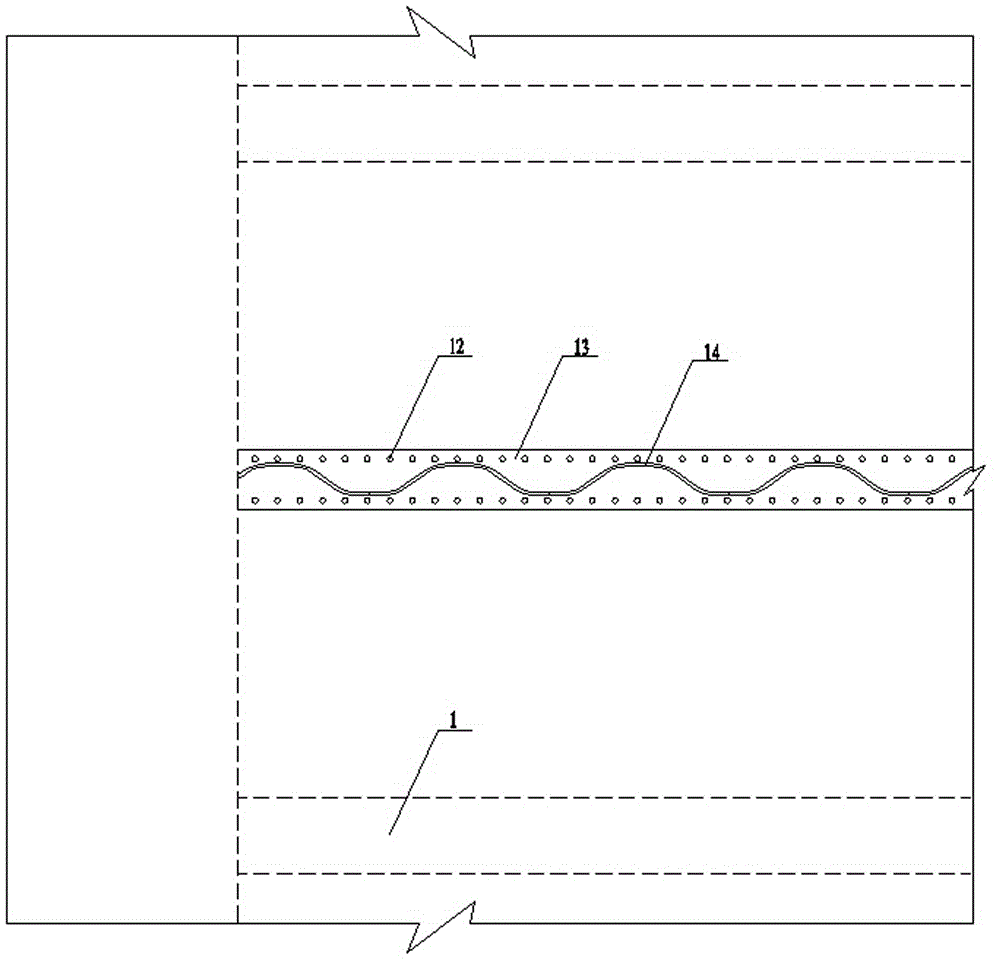

[0025] Anchor bolt 12 selects chemical anchor bolt in the present embodiment, combines Figure 1 to Figure 4 Shown, the construction method of the concrete box girder shear reinforcement based on the corrugated steel web of the present invention, carries out by following steps successively:

[0026] 1) Carry out construction lofting and positioning on the box girder top plate 2 and box girder bottom plate 3: determine the following positions through this lofting: the center line of the longitudinal box girder box chamber 4, that is, the center direction of the corrugated steel web; the anchor bolts embedded in the box girder top plate Hole location; box girder bottom slab planting reinforcement location; post-cast concrete vertical formwork location;

[0027] 2) Treatment of the reinforcement joint surface: Grinding, cleaning and dust removal are performed on the reinforcement joint surface area of the box girder top plate 2 and the box girder bottom plate 3. Under certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com