Reinforcing construction method based on wet-joint-free segment precast concrete box girder

A prefabricated concrete and construction method technology, applied in bridge reinforcement, bridges, bridge parts, etc., can solve the problems of post-reinforcement of precast concrete box girders without wet joints, and improve the distribution of principal stress and shear force , The effect of large construction work area and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

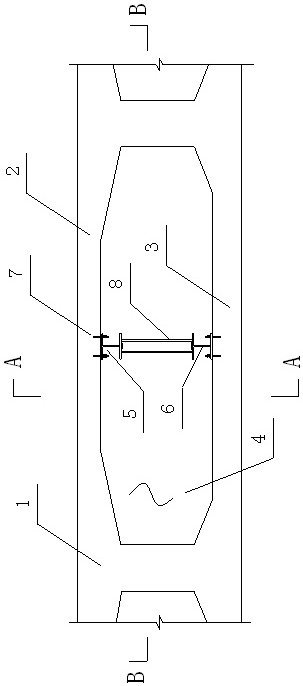

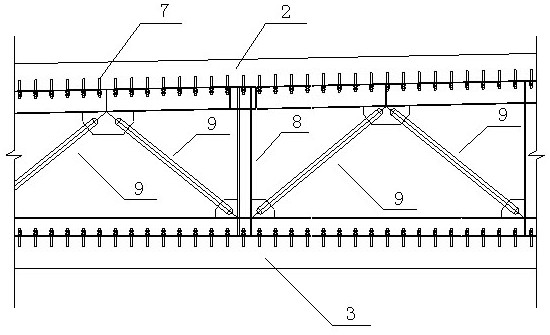

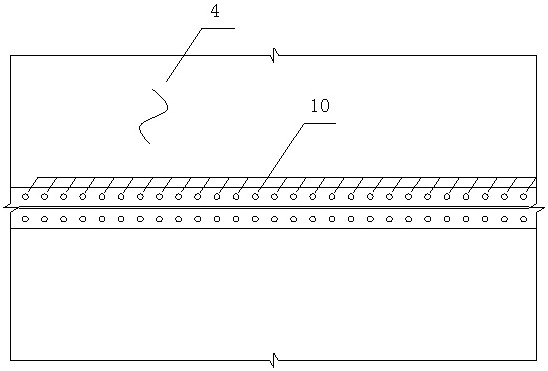

[0038] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] In this embodiment, the anchor bolt 7 is an 8.8-grade chemical anchor bolt with a diameter of 20mm, and the chemical anchoring agent is an anchoring agent containing quartz sand, curing agent and modified resin; the upper chord 5 and the lower chord 6 are Q345D grade 368×22 I-shaped steel; the vertical bar 8 is made of Q345D grade φ152 (t=18) seamless steel pipe; the caulking agent is made of modified epoxy resin glue; related requirements.

[0040] to combine Figure 1 to Figure 3 As shown, the reinforcement construction method based on the prefabricated concrete box girder of the non-wet joint segment of the present invention, carries out successively according to the following steps:

[0041] 1) Construction positioning and lofting: carry out construction lofting and positioning on the box girder top plate 2 and box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com