Method for manufacturing corona resistant transposition winding wires

A technology of transposition winding and manufacturing method, applied to circuits, electrical components, insulated cables, etc., can solve problems such as temperature rise of transformers and power transmission equipment, influence on safe operation of transmission and transformation lines, interference of radio and communication lines, etc. Achieve uniform electric field, reduce electromagnetic pollution, and save active power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

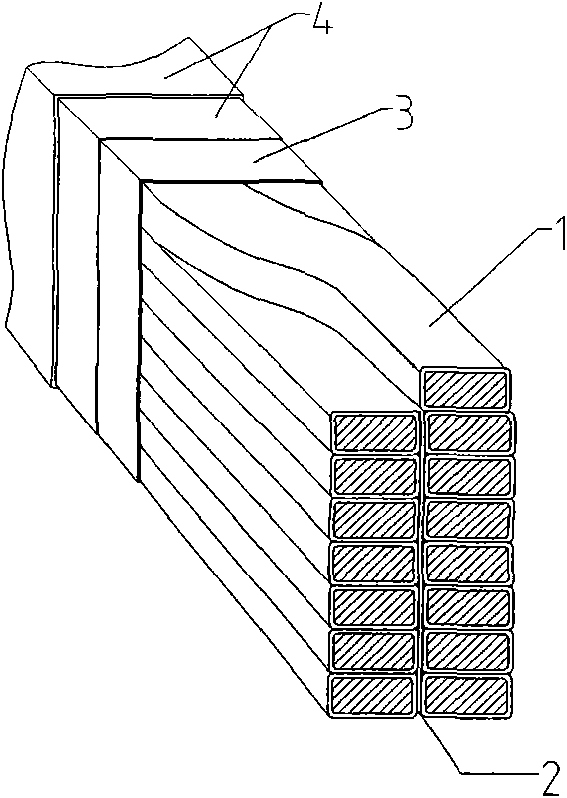

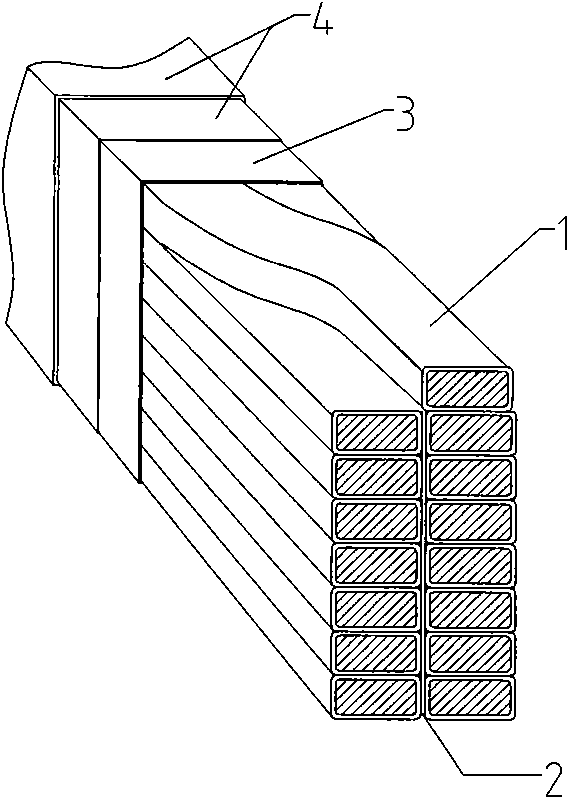

[0015] Such as figure 1 As shown, the structure of the corona-resistant transposition winding wire includes: an enamelled flat wire core 1, a backing paper 2, and an insulating layer 4; An insulating layer 4 is provided on the outside of the enamelled flat wire core 1 as a whole; the feature is that a corona-resistant thin film layer 3 is provided between the enamelled flat wire core 1 and the insulating layer 4 .

[0016] The corona-resistant thin film layer 3 is a polyimide insulating thin film layer containing nanoscale inorganic compounds.

[0017] The specific steps of its preparation method include:

[0018] (1) The wire core is composed of 5-83 copper or aluminum enamelled flat wires to form two rows in which the wide surfaces are in contact with each other. Usu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com