Swing type bilateral non-sine drive device of continuous casting crystallizer

A continuous casting crystallizer and driving device technology, applied in the field of continuous casting, can solve the problems of low operating precision, poor operating mode, and difficult control, etc., achieve superior wear resistance, reduce operating and maintenance costs, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

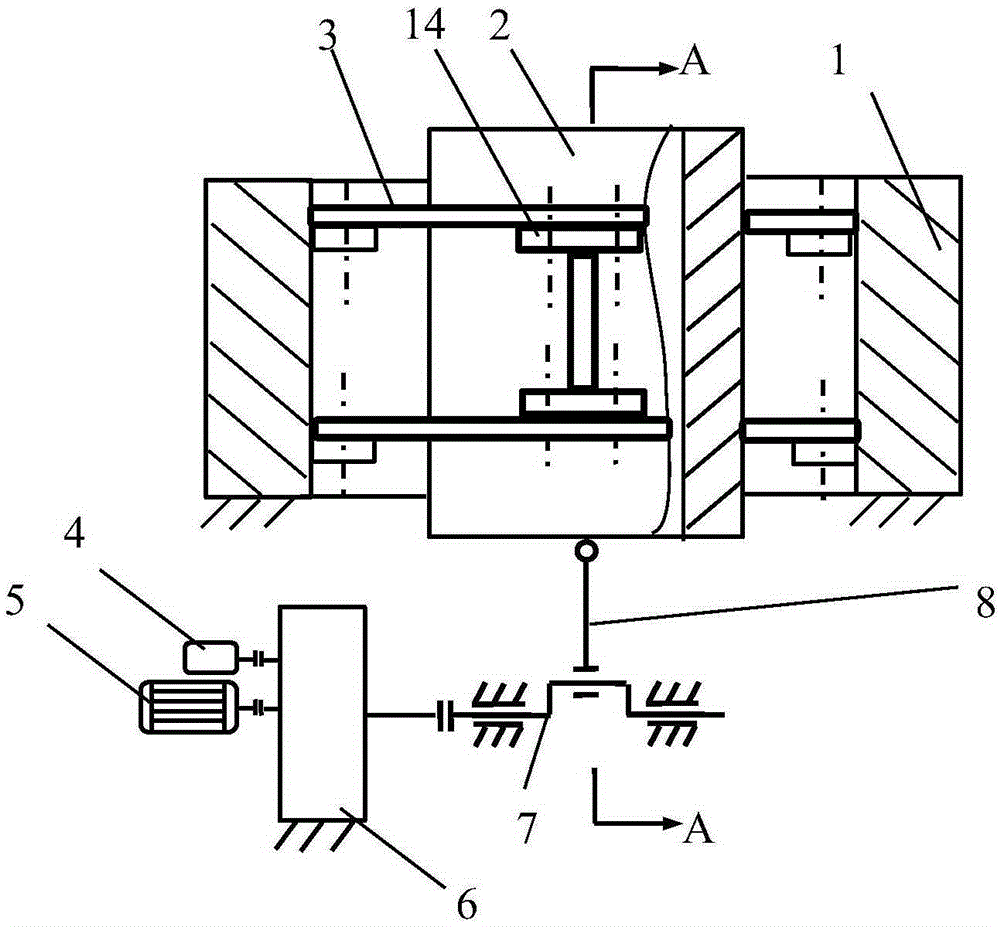

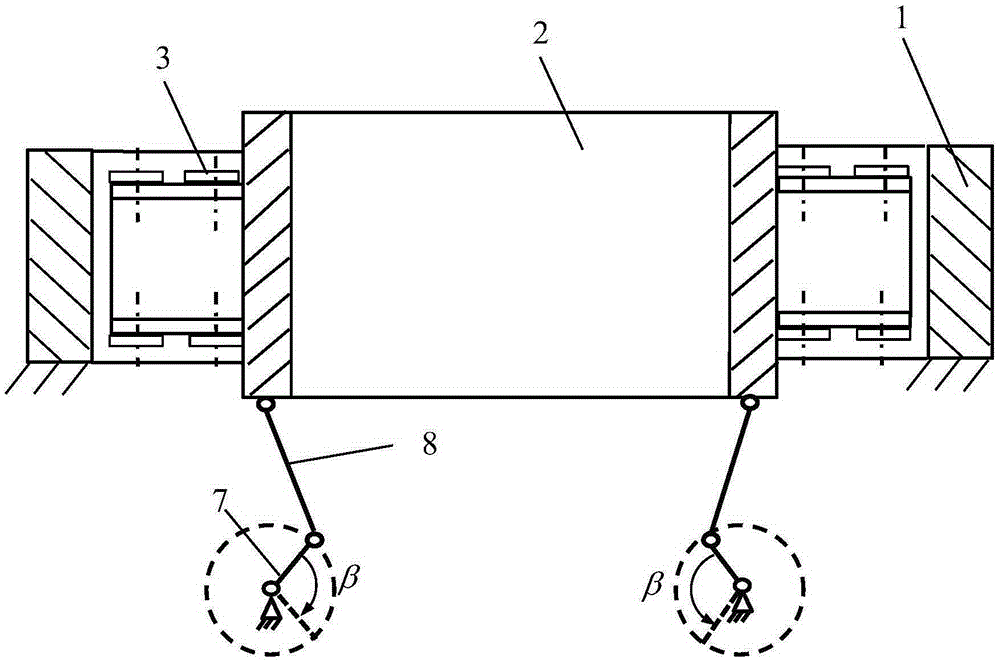

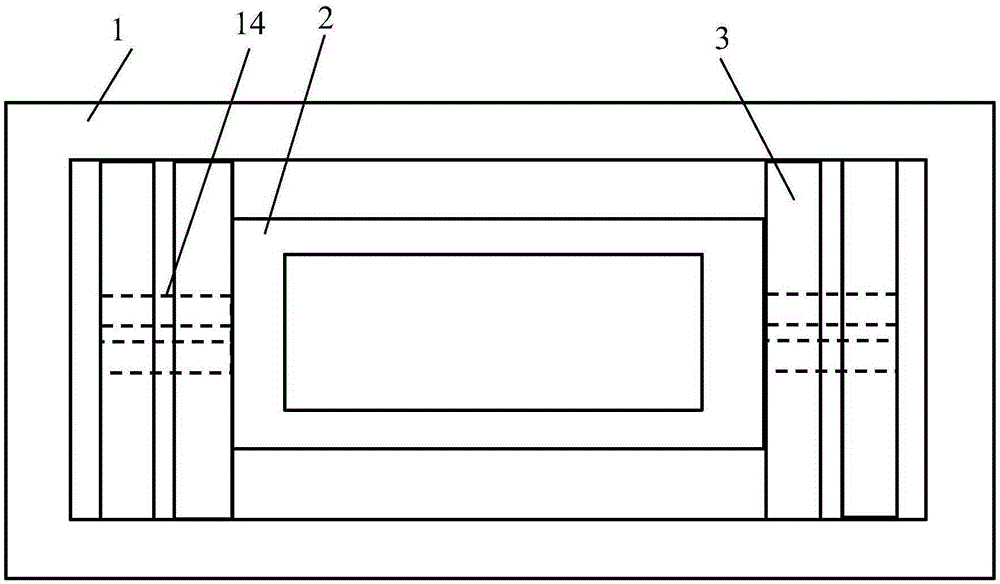

[0033] exist figure 1 , figure 2 and image 3 In the schematic diagram of the continuous casting mold swing type double-sided non-sinusoidal driving device shown, the crystallizer vibrating table is composed of a fixed frame 1, a vibrating frame 2 and the connecting pieces between them, and a vibrating frame is arranged in the fixed frame , each side of the two narrow sides of the vibrating frame is provided with a total of four guide leaf springs 3, the two ends of the guide leaf springs are respectively connected to the fixed frame through connectors, and the middle part of the guide leaf springs is connected to the I-shaped support beam 14 through the connectors. The fixed end of the I-shaped support beam is vertically connected with the middle part of the narrow surface of the vibrating frame. The crystallizer vibrating table of this scheme is used in straight arc continuous casting machines. The vibrating frame reciprocates along a straight line, and the centerlines of...

Embodiment 2

[0048] The structure of this embodiment is basically the same as that of Example 1, except that the active component connection mode of the differential gear train transmission mechanism 6 is changed, such as Figure 11 As shown, the constant speed motor 5 is connected with the small sun gear 12 through a coupling, the servo motor 4 is connected with the driving gear 9 through a coupling, and the driving wheel 9 drives the planet carrier 11 to rotate through the fixed gear on the planet carrier 11 . After the angular velocity of the constant speed motor 5 and the servo motor 4 is synthesized by the differential gear train 6 , the motion is transmitted to the shock shaft 7 through the big sun gear 10 .

[0049] The given crystallizer vibration parameters are the same as the first group of vibration parameters in Embodiment 1: amplitude h=4mm, vibration frequency f=180min -1 , the waveform eccentricity slope α=0.2, then setting the speed of the servo motor 4 can achieve the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com