Framework structure of amorphous alloy transformer

A skeleton structure, amorphous alloy technology, applied in transformer/inductor components, transformer/inductor cores, electrical components, etc., can solve problems such as skeleton compression of iron core columns, increase in coil circumference, and increase in load loss , to achieve the effect of reducing assembly time, reducing no-load loss, and avoiding increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

[0011] Usually, the iron core columns of each phase coil in the amorphous alloy transformer are assembled by an even number of individual iron core columns with the same shape and size, and the assembled iron core columns are rectangular in shape.

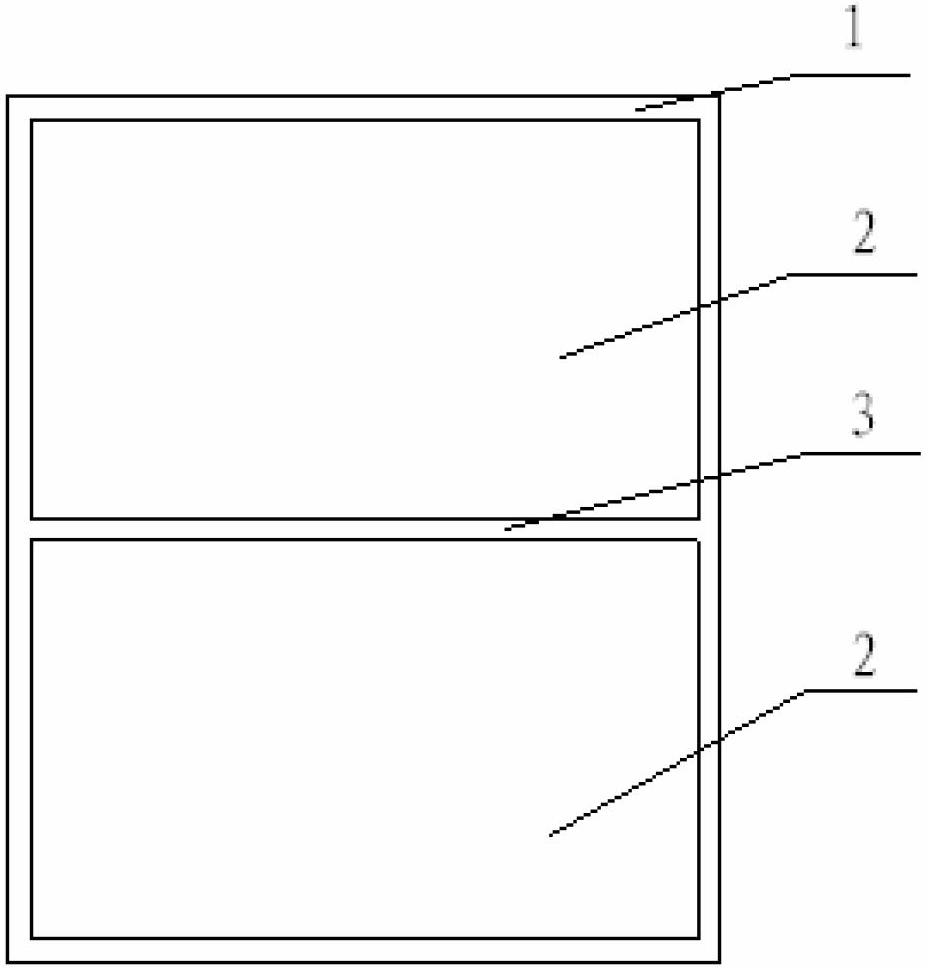

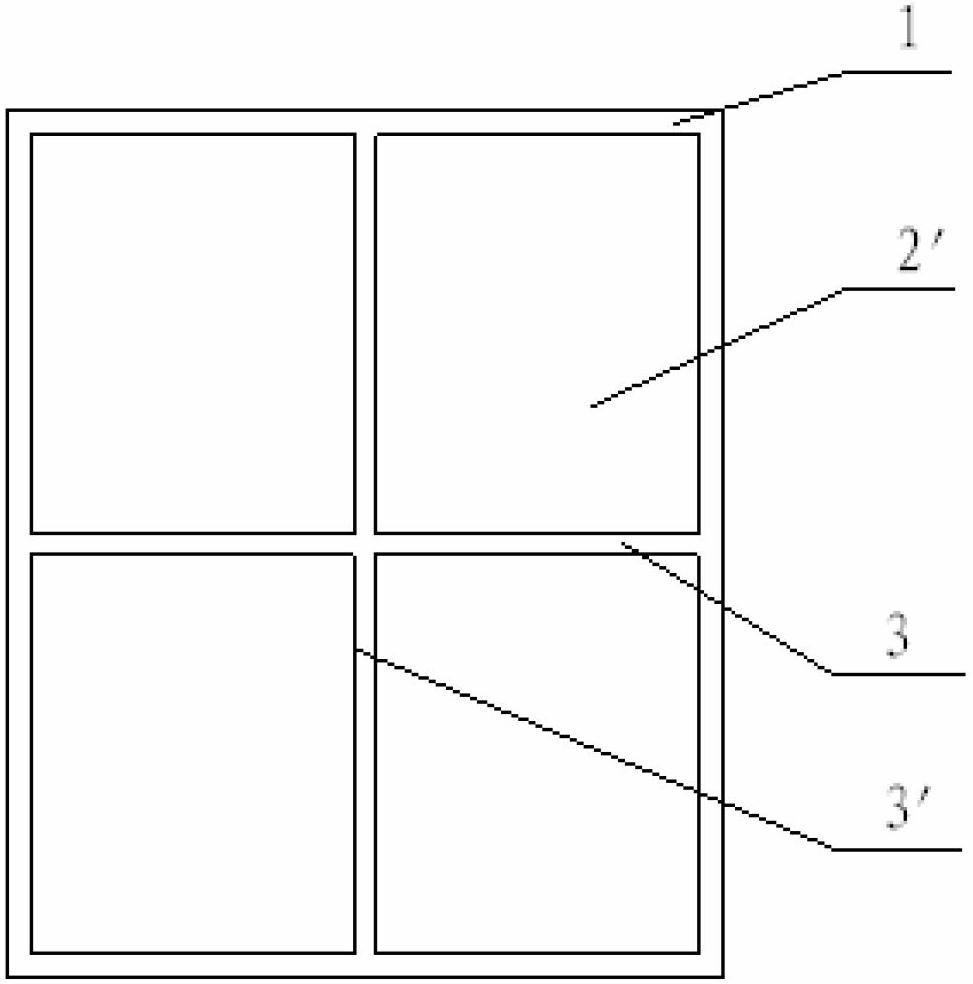

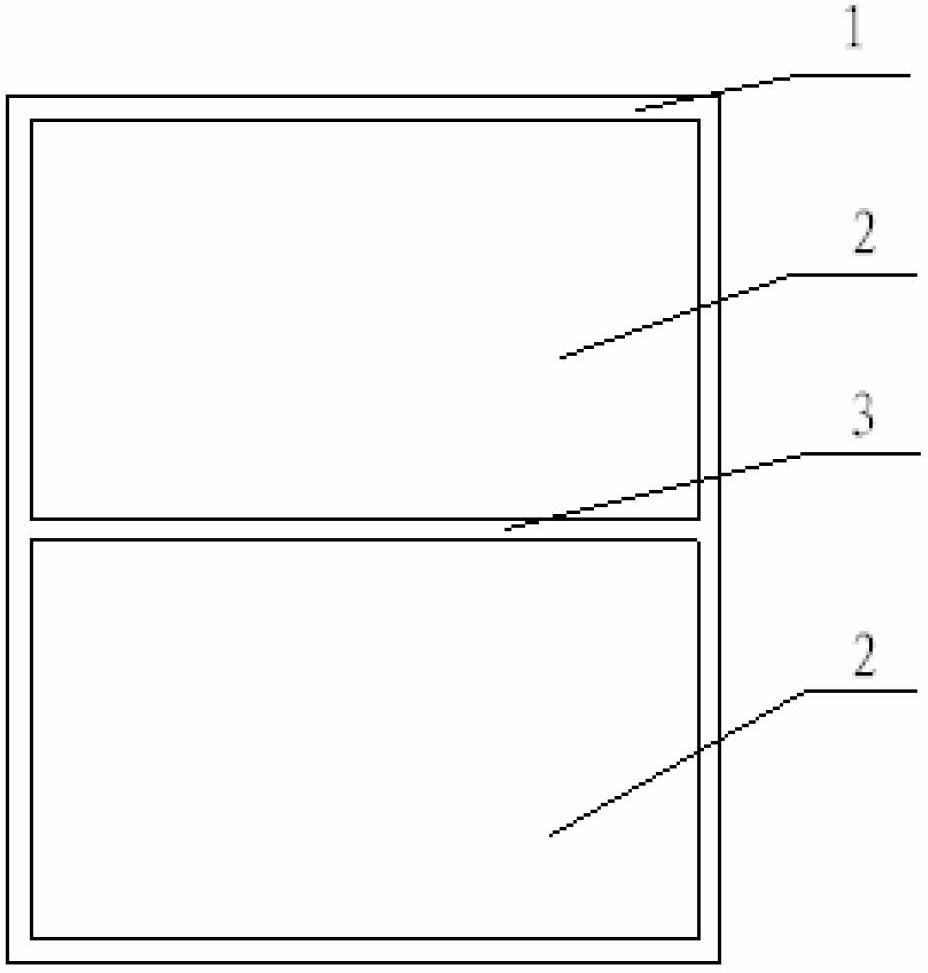

[0012] see figure 1 , the skeleton structure of the amorphous alloy transformer of the present invention is a hollow cylinder, the cross-sectional shape of the skeleton inner chamber is rectangular, and the inner chamber of the skeleton 1 is separated into several unit spaces 2 of the same shape by a partition plate 3, if a single There are two body core columns, and there are also two unit spaces 2, so that the two single core columns can be inserted into the unit space 2 one by one accordingly.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com