Structure for fastening amorphous alloy transformer body and method for assembling transformer body

A fastening structure, amorphous alloy technology, applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, electrical components, etc., can solve problems such as unsuitable assembly methods, and improve short-circuit resistance , reduce noise, and avoid the effect of iron core stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

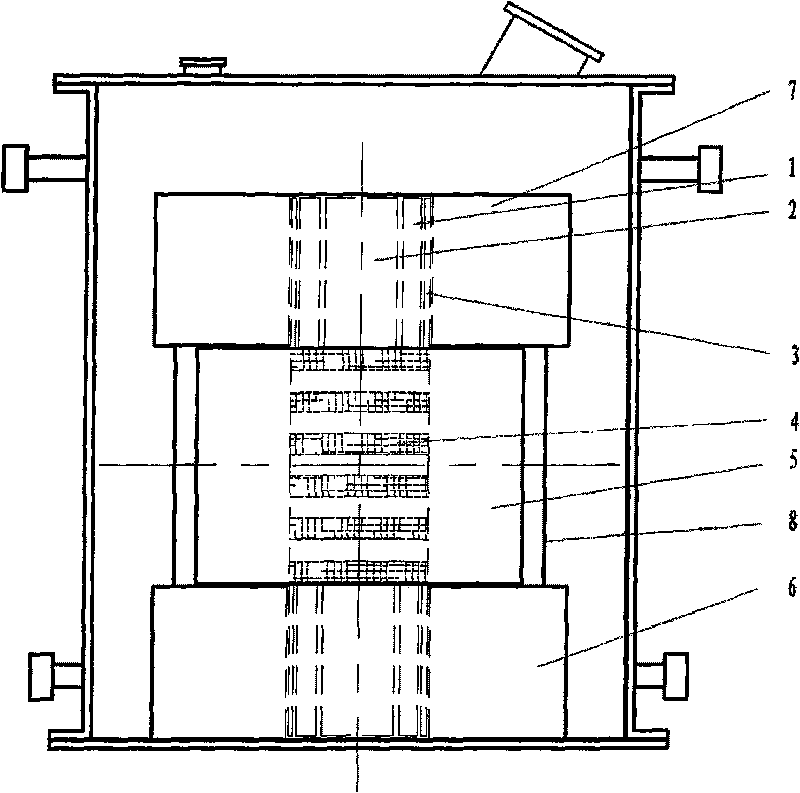

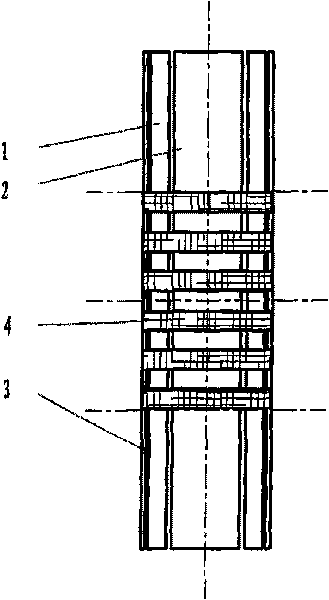

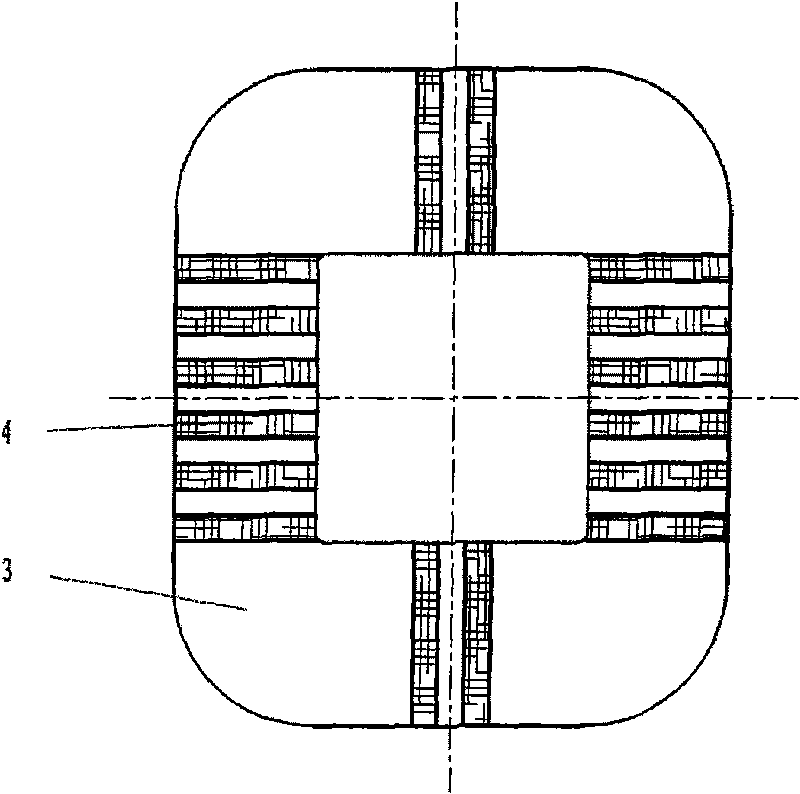

[0028] The body fastening structure of the amorphous alloy transformer of the present invention includes a low-voltage coil 1, a high-voltage coil 2, a pressure plate 3, a binding strap 4, a core column 5, a lower clamp 6, an upper clamp 7, and a limit rod 8. The phase windings are alternately arranged in the form of a low-voltage coil and a high-voltage coil. The pressure plate 3 is placed outside the coil at the end of the phase winding, and the phase winding and the pressure plate 3 are fastened by a binding band 4 to form an independent fastened coil. Phase winding; one or more phase windings are set on the core column; the lower and upper parts of the coils in the phase winding are respectively embedded in the grooves of the lower fixture and the upper fixture, and the spacers are used between the pressure plate and the walls of the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com