Supporting bar favorable for dissipating heat of oil-immersing amorphous alloy transformer

An amorphous alloy and transformer technology, applied in the field of amorphous alloy iron core manufacturing, can solve the problems of unfavorable heat dissipation of stay curtains, and achieve the effect of accelerating oil flow rate, obvious effect, and improving heat dissipation effect

Inactive Publication Date: 2014-01-29

STATE GRID CORP OF CHINA +1

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the above-mentioned technical problem that the stay curtain used in the oil channel of the existing amorphous alloy transformer is not conducive to heat dissipation, the present invention provides a stay that is beneficial to the heat dissipation of the oil-immersed amorphous alloy transformer. By changing the structure and pasting method of the stay and thickness, to improve the heat dissipation coefficient and reduce the temperature rise of the transformer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

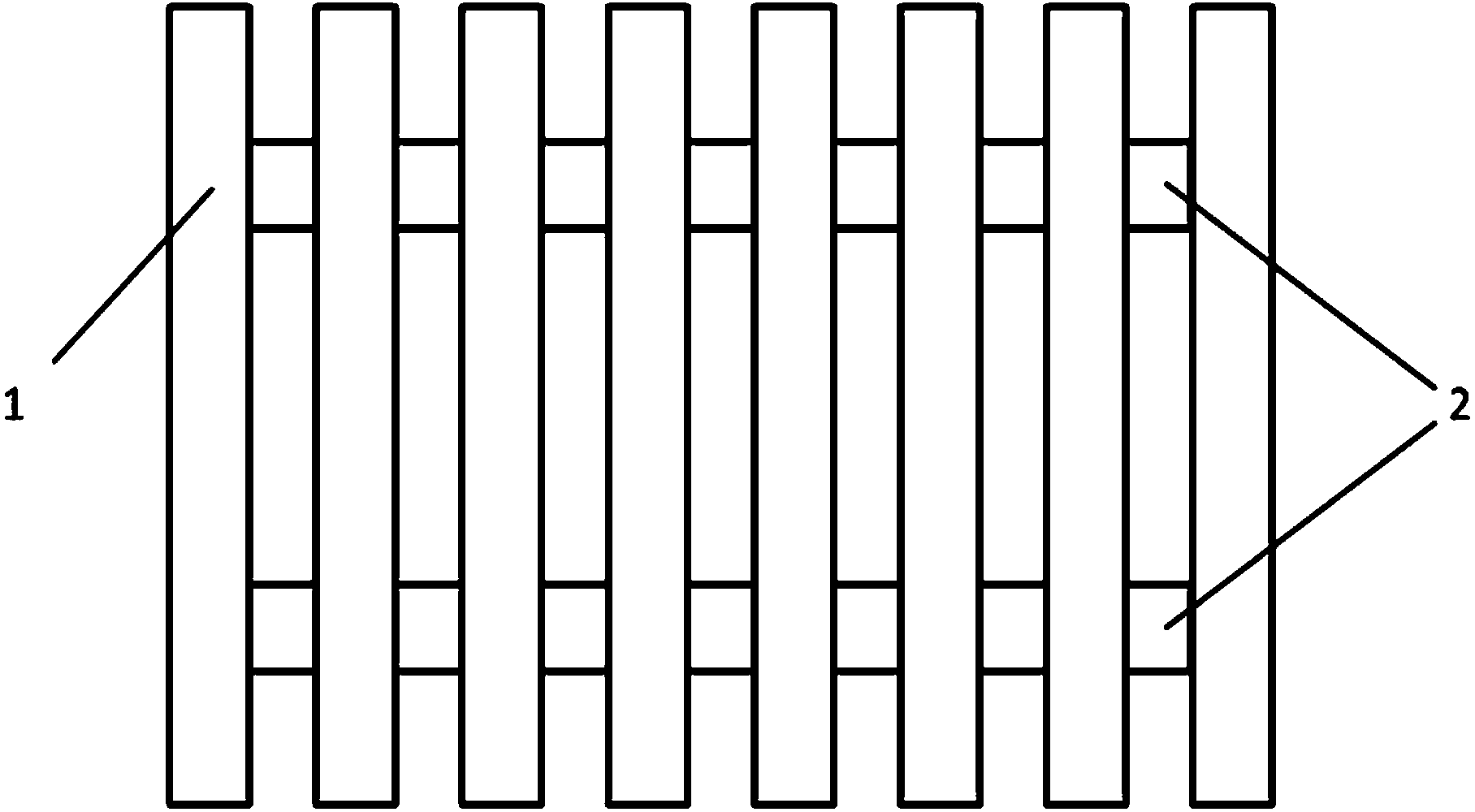

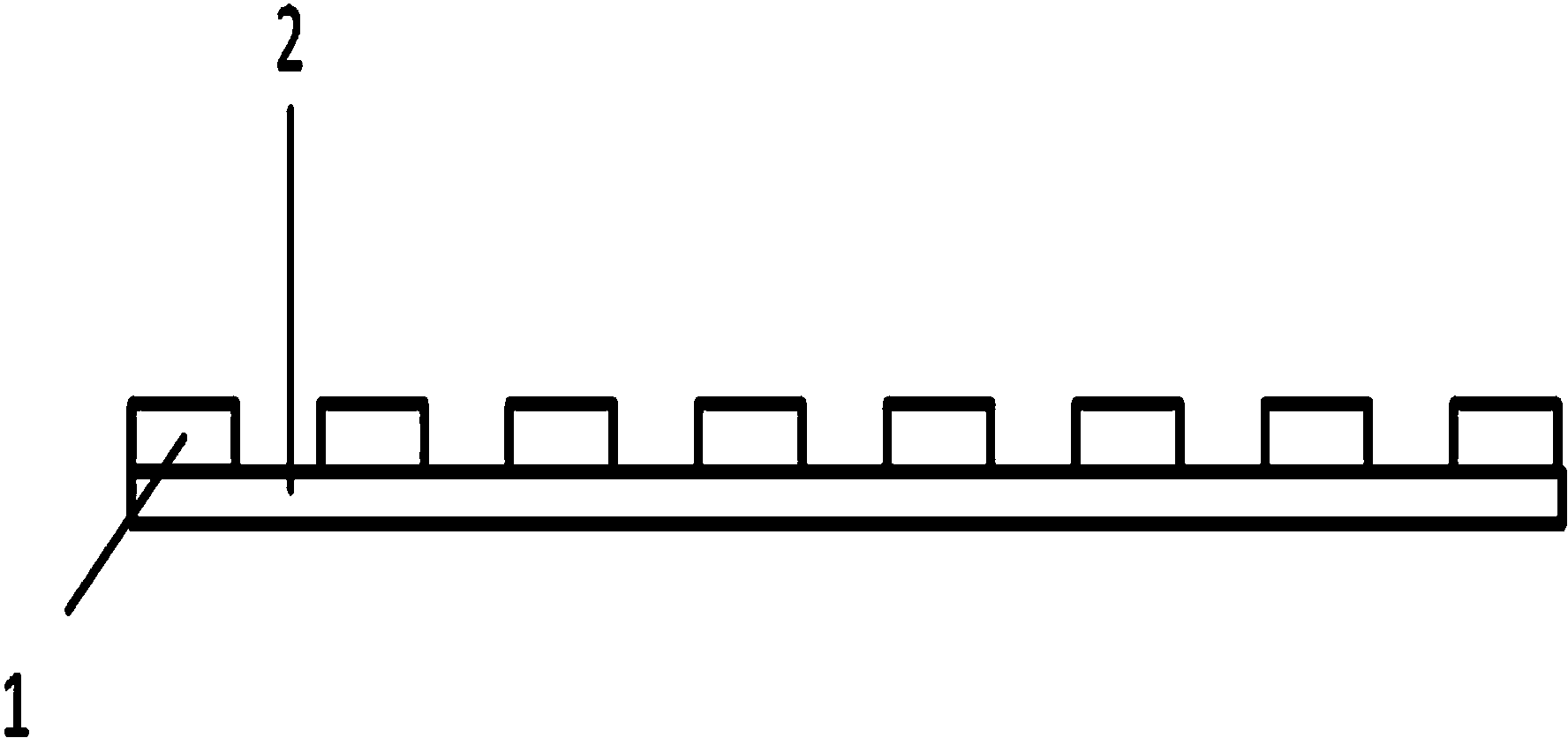

The invention belongs to the technical field of amorphous alloy iron core manufacturing, and particularly relates to a supporting bar favorable for dissipating heat of an oil-immersing amorphous alloy transformer. Temperature rising of the transformer is reduced through optimizing the oil-immersing amorphous alloy transformer. The supporting bar comprises supporting bar bodies, glue applying straps are connected to the lower surfaces of the supporting bar bodies, and the number of the glue applying straps is more than one. The thickness of the supporting bar bodies in an oil channel of the transformer is increased, the area of the oil channel can be increased, the supporting strength of the supporting bar bodies is improved, a breakdown voltage is increased, and the heat dissipating effect of the transformer is improved. The two narrow-piece glue applying straps are adopted to paste a fence-type structure of the supporting bar bodies, not only is full contact between oil and copper wires facilitated and thus is the temperature rising of the transformer reduced, but also machining difficulty of the transformer is favorable for being reduced, the transformer can be machined faster and more conveniently, and the temperature of the transformer is lowered. Thus, the remarkable advantages that the heat dissipating coefficient is improved and the temperature rising of the transformer is reduced are achieved, and the supporting bar is simple and reasonable in structure, obvious in effect and favorable for being widely promoted and applied.

Description

technical field [0001] The invention belongs to the technical field of amorphous alloy iron core manufacturing, and in particular relates to a stay that facilitates the heat dissipation of an oil-immersed amorphous alloy transformer, and reduces the temperature rise of the transformer by optimizing the structure of the oil-immersed amorphous alloy transformer. Background technique In the 1990s, amorphous alloy transformers were gradually introduced into my country's power market as a high-efficiency and energy-saving product. It used amorphous alloy materials instead of silicon steel sheets to manufacture transformers. Amorphous alloy coil oil passages and main air passages generally use stays or stay curtains. The stay curtain is usually a whole piece of glued paper glued in parallel to several stays, which will cause a piece of glued paper between the oil channel and the copper wire, which will cause poor heat dissipation and increase the temperature rise of the transfor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01F27/08H01F27/30

Inventor 王磊于在明唐红杜威杨璐羽

Owner STATE GRID CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com