Amorphous alloy transformer body structure having short-circuit resistant capability

A technology of anti-short circuit ability and amorphous alloy, which is applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, transformer/inductor parts, etc., and can solve the problem of poor short circuit resistance of rectangular winding , to achieve the effect of improving short-circuit resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

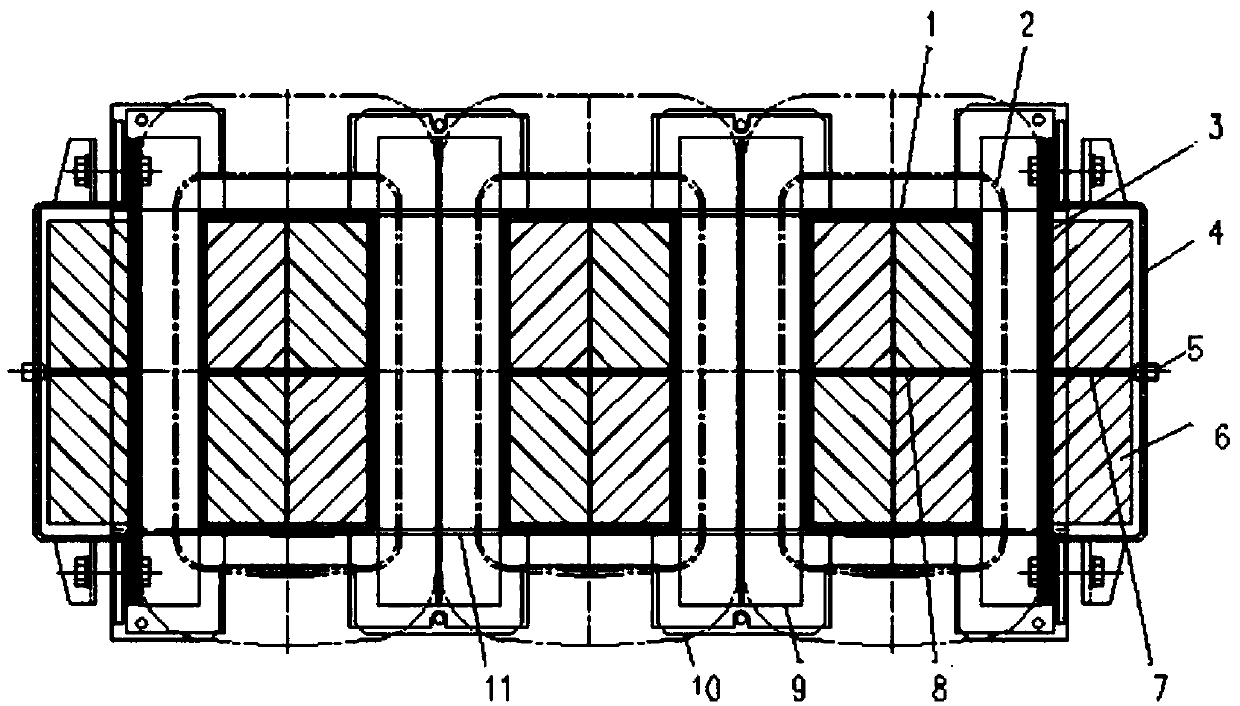

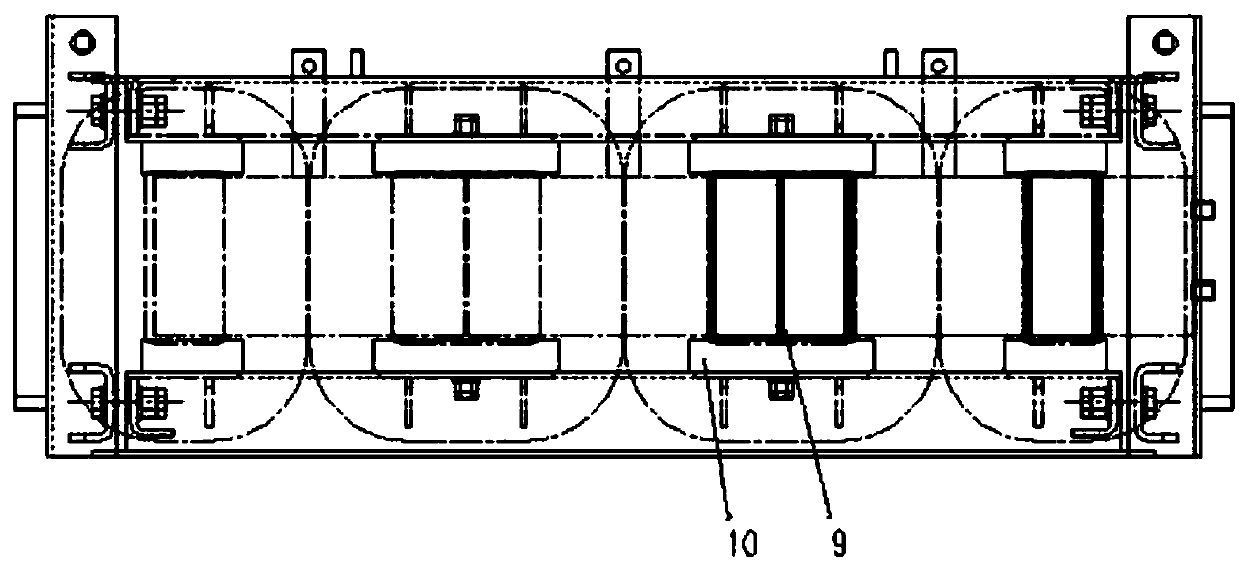

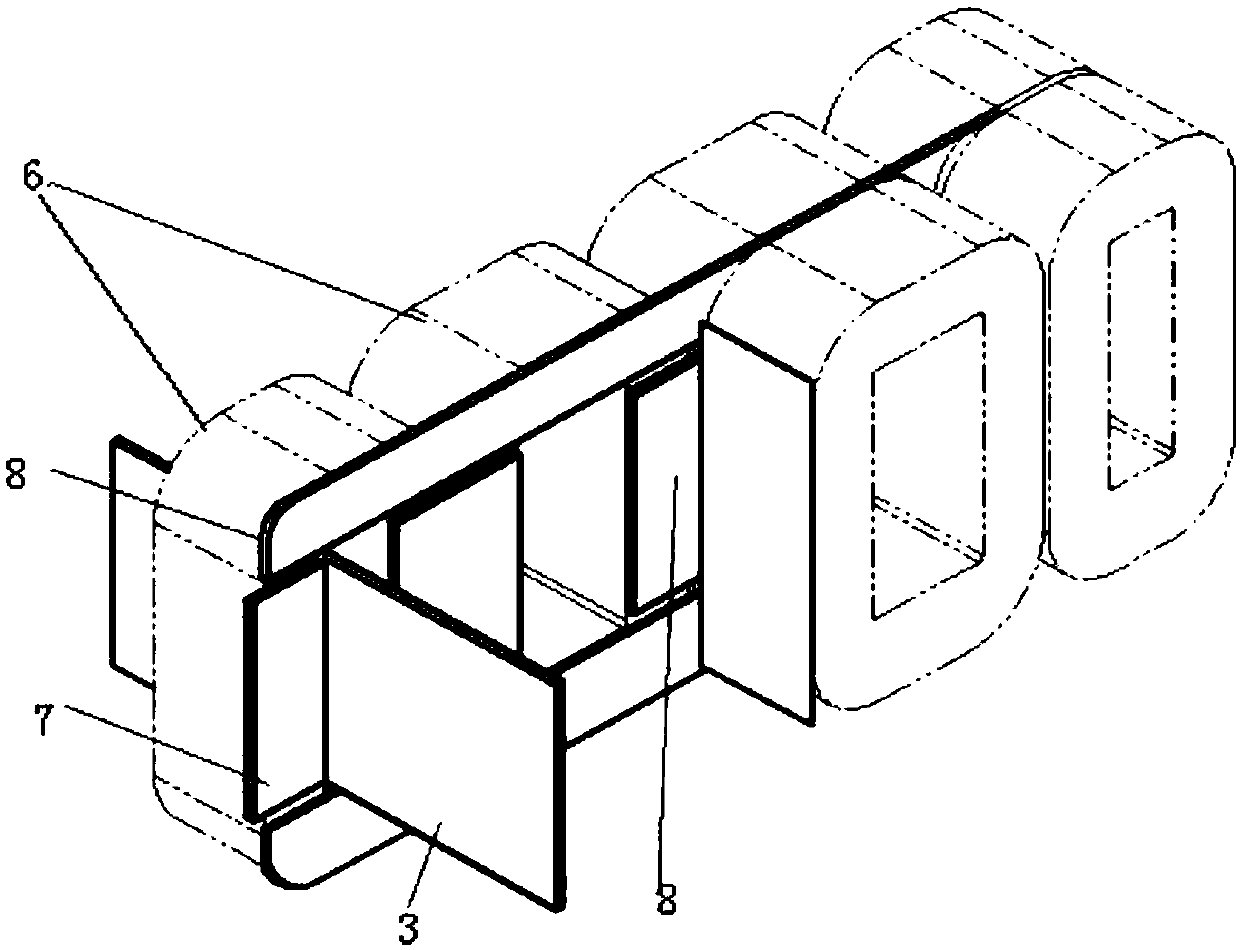

[0019] An amorphous alloy transformer body structure with short-circuit resistance capability. It is a three-phase four-frame core structure, including upper and lower layers of amorphous alloy core 6 (including large and small frames), and A, B, and C three-phase windings 2 , It also includes C-shaped insulating plates 9 distributed between the A-phase and B-phase windings, between the B-phase and C-phase windings, and outside the A-phase winding and the C-phase winding, and arranged in the A, B, and C three-phase low-voltage windings The hard insulating cylinder 1, the left and right side pressure plates 3 symmetrically distributed on the left and right sides of the body structure, the upper and lower pressure plates 10 symmetrically distributed on the upper and lower sides of the body structure; the two layers of amorphous alloy iron cores 6 are used to support the left and right sides. The first reinforcement plate 7 of the pressure plate 3 is spaced from the second reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com