Low-noise amorphous alloy transformer iron core

A transformer core and amorphous alloy technology, applied in the field of transformers, can solve the problems of amorphous alloy transformer noise and other problems, and achieve the effects of low cost, noise reduction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

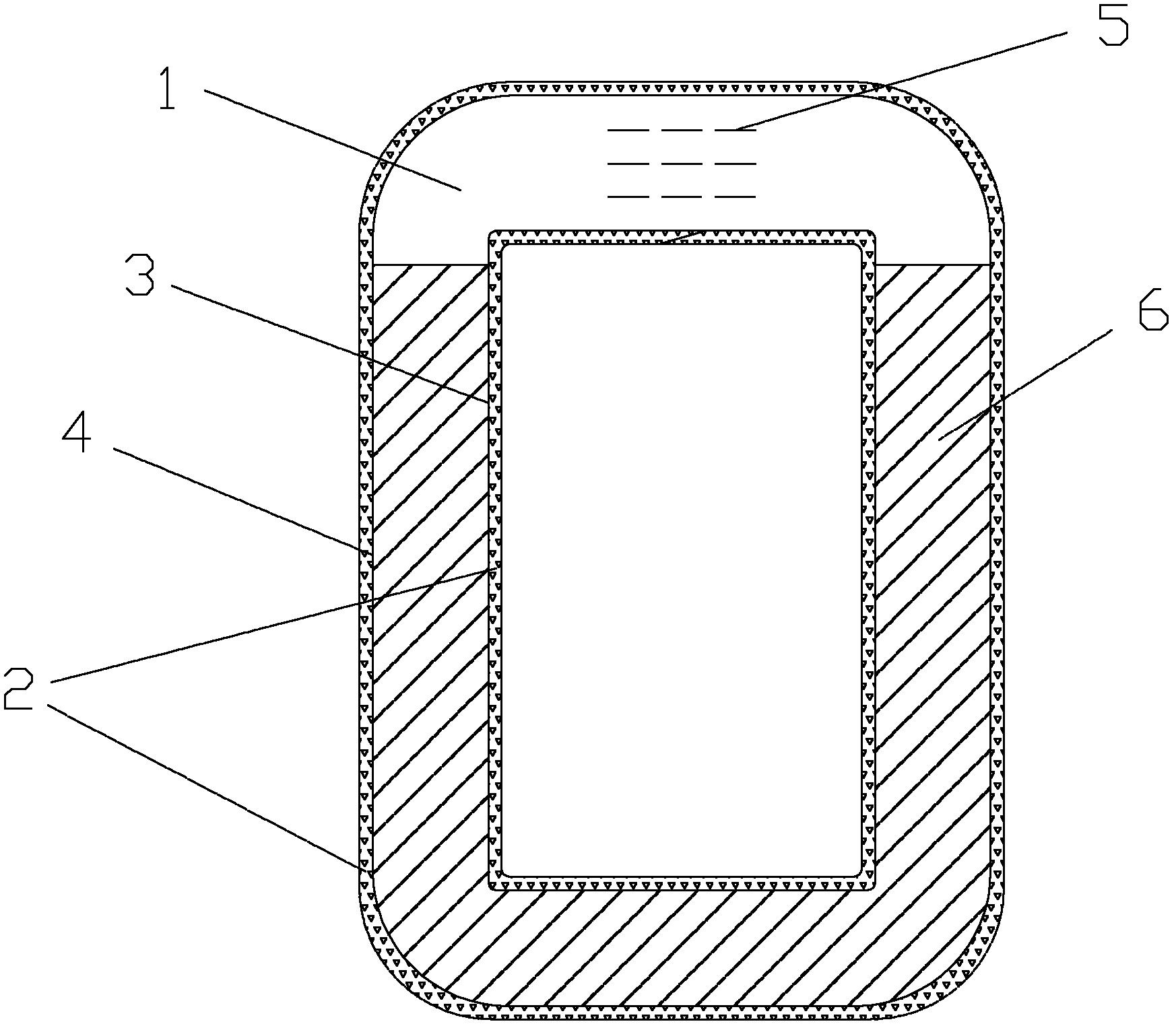

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, exemplary embodiments are exemplified below and described in detail in conjunction with the accompanying drawings.

[0031] Considering that the magnetostriction coefficient of the amorphous alloy is relatively high, the vibration of the amorphous iron core caused by magnetostriction is relatively small, the vibration magnitude is relatively large, and the corresponding noise is also relatively large. In order to reduce noise, the present invention arranges sound-insulating felts on both the inner surface and the outer surface of the amorphous alloy iron core to effectively isolate the propagation path of noise and significantly reduce the noise of the amorphous alloy iron core.

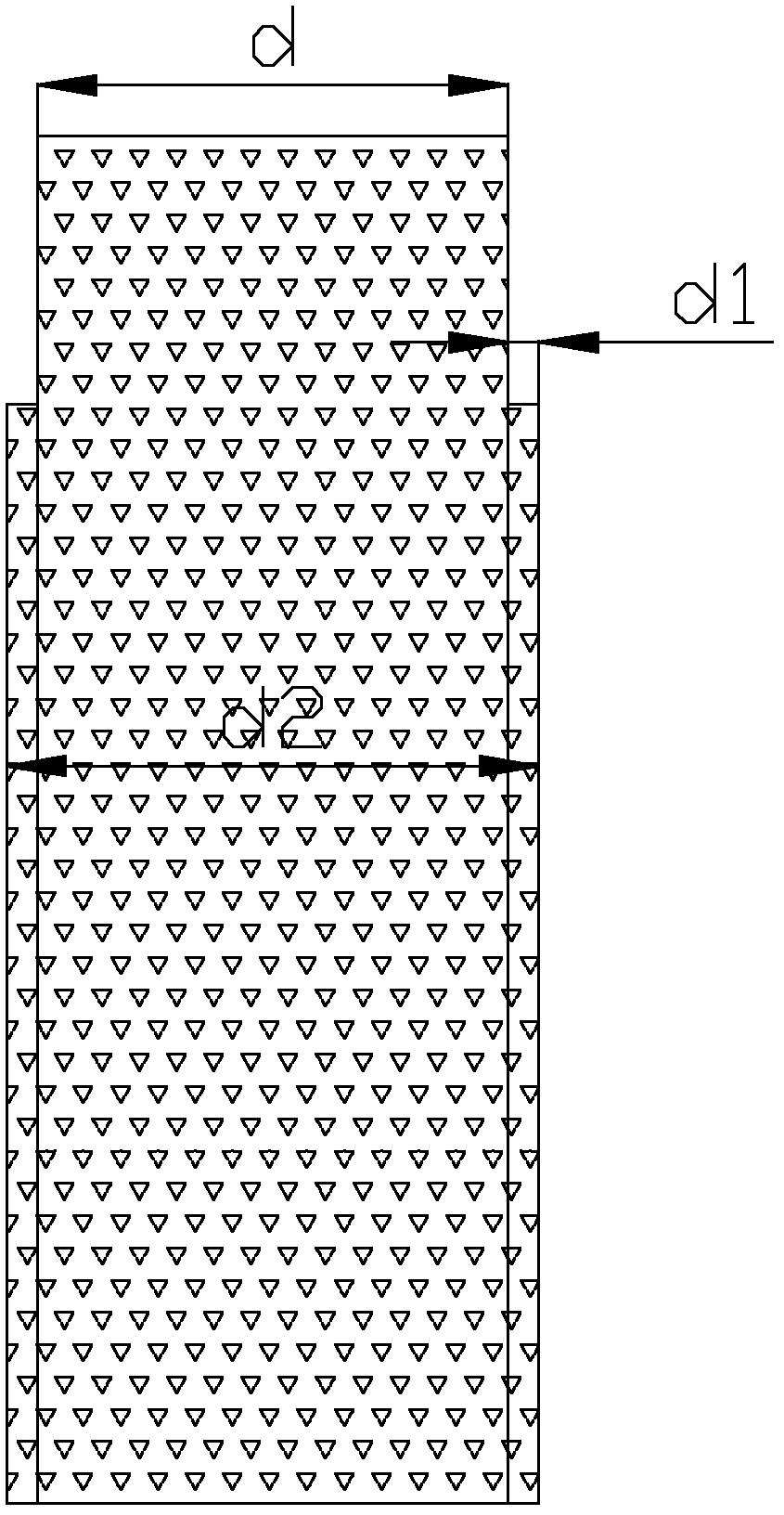

[0032] For details, please refer to figure 1 , which is a schematic structural view of an amorphous alloy transformer core provided by an embodiment of the present invention. As shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com