Light aggregate concrete sandwich thermal insulated block, and its production method

A technology of lightweight aggregate concrete and thermal insulation blocks, which is applied in building materials, ceramic molding machines, manufacturing tools, etc., can solve the problems of reducing the air-conditioning refrigeration temperature and the opening time of the air-conditioning, increasing the consumption of electric energy and heat energy, and increasing the consumption investment, etc. Low production cost, reduced heat energy transfer, increased thermal insulation and sound insulation and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] 1. Light aggregate concrete sandwich insulation block structure:

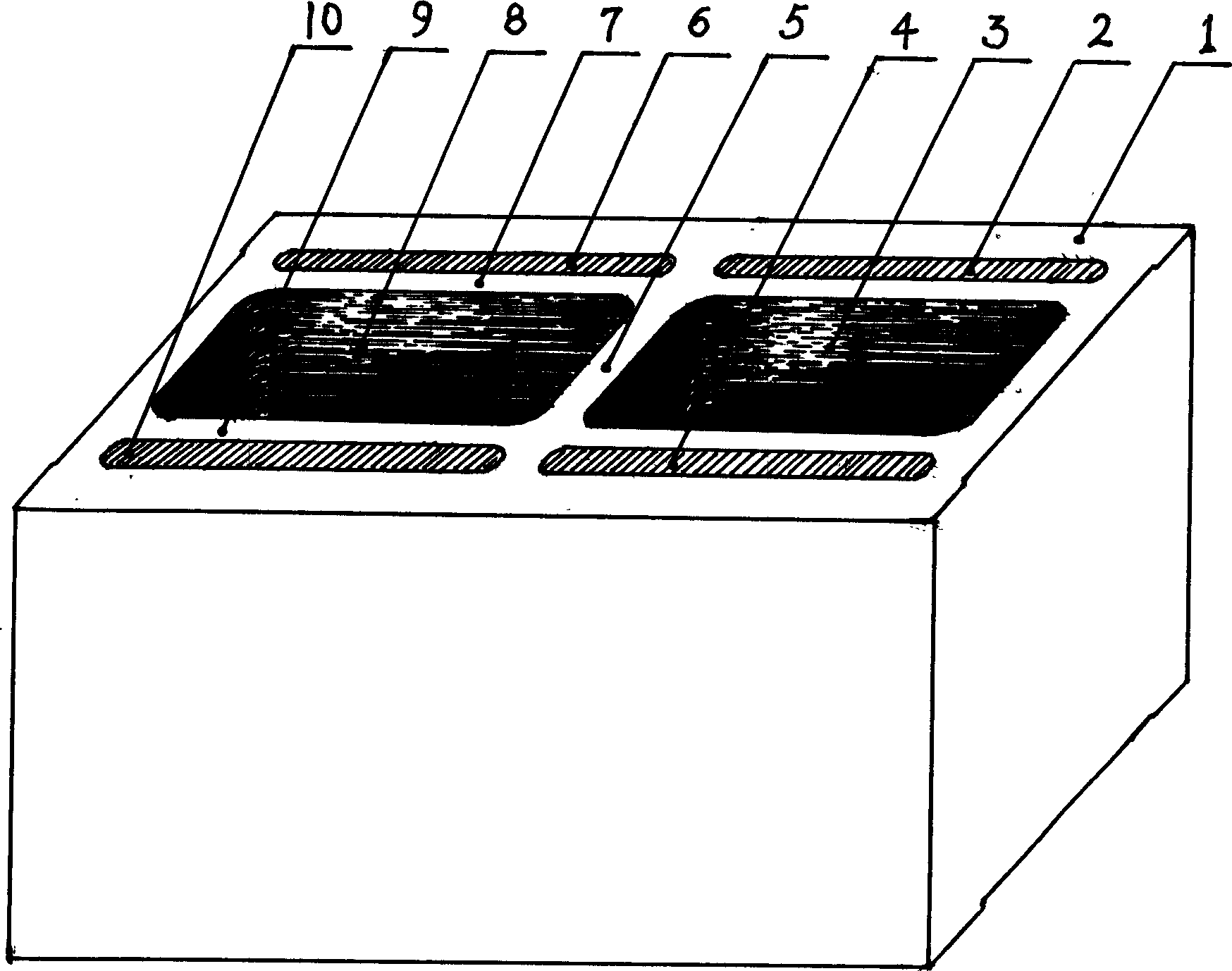

[0009] in the attached figure 1 Among them, the lightweight aggregate concrete sandwich insulation block consists of a concrete outer layer (1), a concrete inner compartment (7) and (9), a longitudinal concrete compartment (5) and a sandwich polystyrene foam layer (2), ( 6), (4), (10) form two large hollow chambers (3) and (8) between the concrete inner compartment (7) and (9) and the middle longitudinal concrete compartment (5). When the light aggregate concrete sandwich insulation block is used for the building wall, the polystyrene foam layers (2), (6), (4), (10) sandwiched between the concrete and the polystyrene foam layer between the concrete The large hollow chambers (3), (8) have all played the role of thermal insulation and sound insulation and environmental protection, so that the indoor and outdoor hot and cold temperatures can not be transmitted to each other, and prevent outdoor noise from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com