Multi-target genetic algorithm based medium-frequency amorphous alloy transformer optimization method

A multi-objective genetic, amorphous alloy technology, applied in the field of optimization of DC distribution network system, can solve the problems of DC bias, transformer magnetic flux saturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing of description, the present invention will be further described.

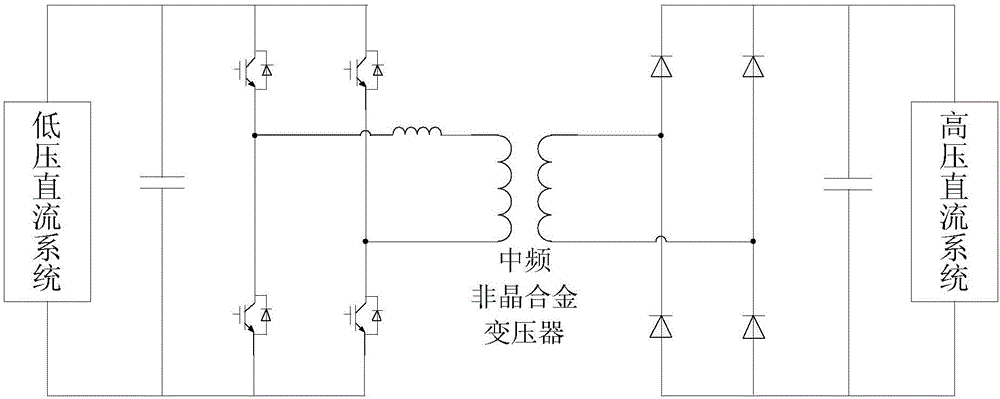

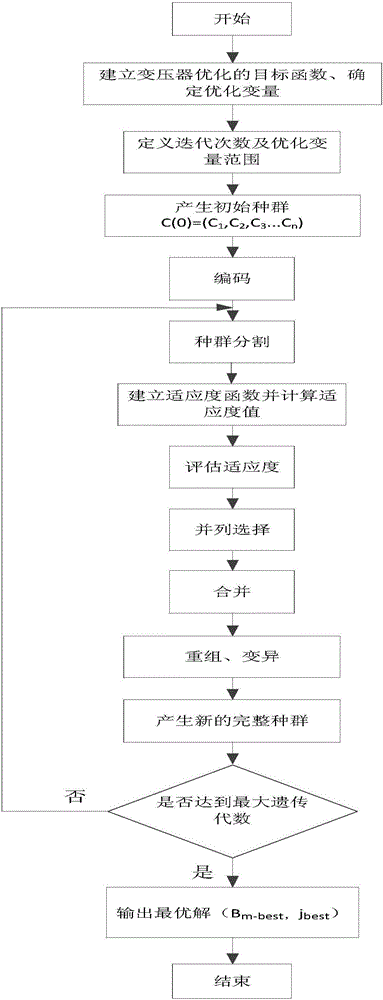

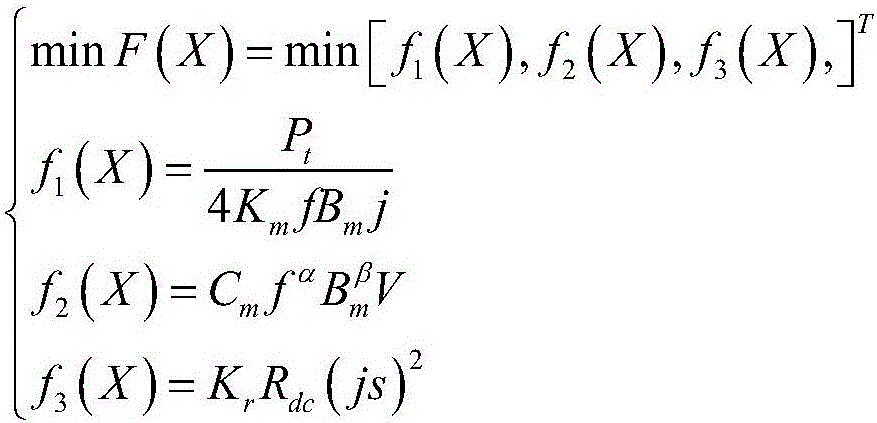

[0047] The present invention provides a method for optimizing an intermediate frequency amorphous alloy transformer based on a multi-objective genetic algorithm. The connection schematic diagram of an intermediate frequency amorphous alloy transformer to be optimized in a DC distribution network is as follows: figure 1As shown, the intermediate frequency amorphous alloy transformer is at the kilohertz level, and realizes the transformation from low-voltage direct current to high-voltage direct current. In order to maximize the efficiency of the transformer and minimize the loss, the multi-objective optimization genetic algorithm (MOGA) is used to optimize the transformer.

[0048] Based on the manufacturer's empirical values and considering the skin effect and proximity effect, the basic parameters of the intermediate frequency amorphous alloy transformer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com