Method for preparing nanophase containing aluminum-magnesium-silicon alloy wire

A nano-phase, silicon alloy technology, used in metal/alloy conductors, cable/conductor manufacturing, conductive materials, etc., can solve the problem of increasing the electron relaxation time, and cannot further improve the strength and conductivity of aluminum-magnesium-silicon alloy wires. , electron scattering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

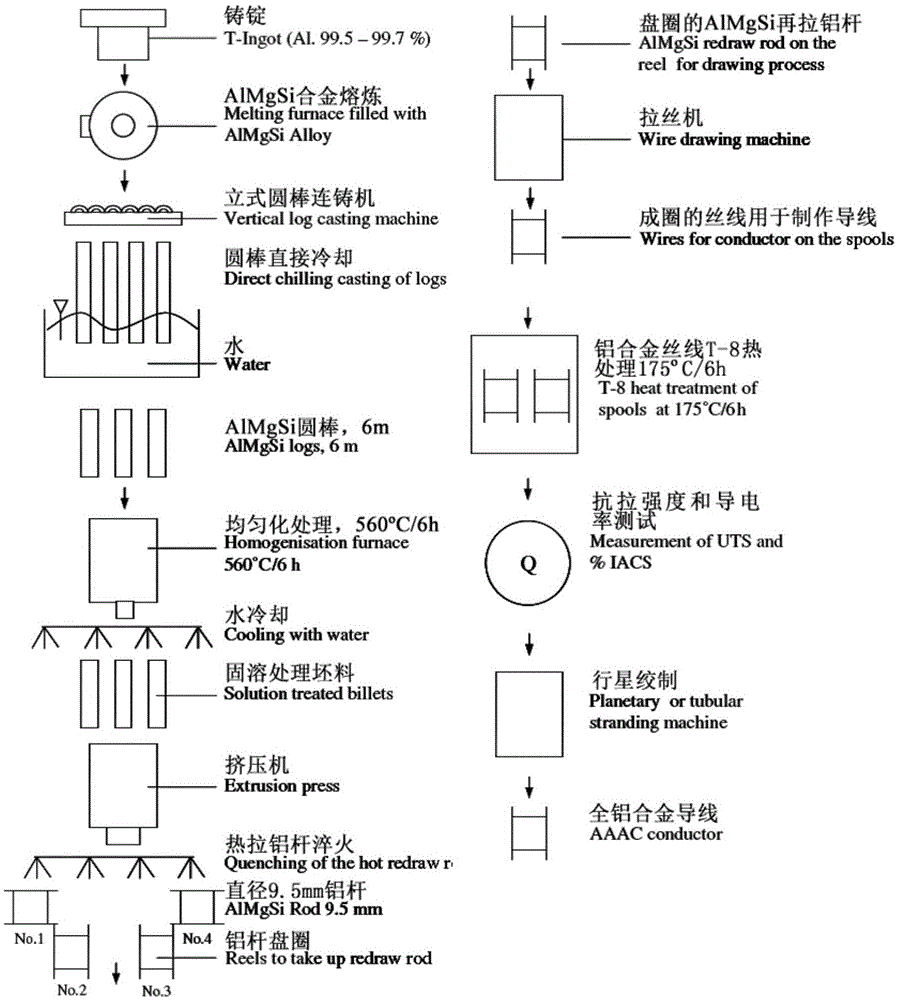

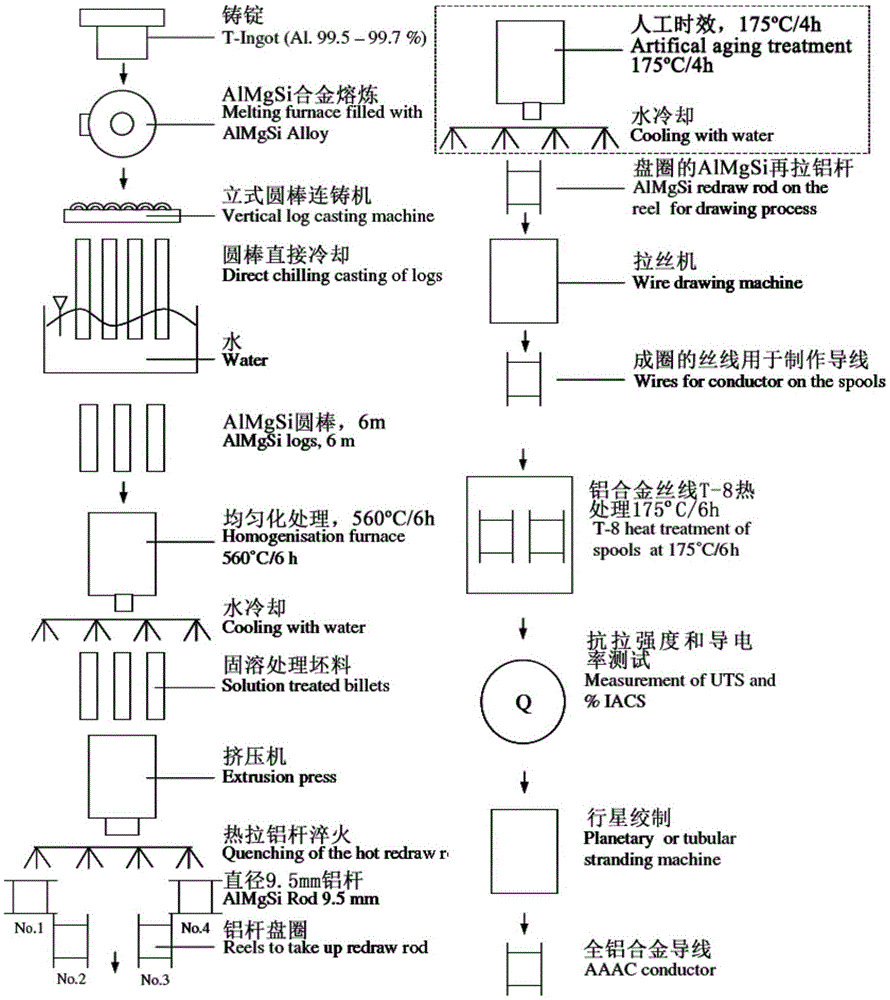

[0071] A method for preparing an aluminum-magnesium-silicon alloy wire containing a nanophase, specifically comprising the following steps:

[0072] Step 1, alloy melting:

[0073] (1) Take the ingredients according to the composition of 6201 aluminum alloy;

[0074] (2) Using an intermediate frequency induction furnace, place the aluminum ingot in the crucible, raise the temperature of the furnace to 730°C, after the aluminum ingot is melted, wrap other alloy elements with aluminum foil and put them into the aluminum liquid, add 1% of the alloy mass Ti was used as a grain refiner, and the temperature was kept for 30 minutes, and N with a purity of 99.9% was used 2 Degassing to obtain 6201 aluminum alloy liquid;

[0075] Step 2, casting:

[0076] A 6201 aluminum alloy round bar with a diameter of 100 mm and a length of 6 m was produced by using a vertical round bar continuous casting machine;

[0077] Sampling and analysis of its chemical composition, 6201 aluminum alloy, ...

Embodiment 1 and comparative example 6201

[0104] Table 2 Example 1 and the tensile strength and conductivity test results of the 6201 alloy wire of comparative example

[0105]

[0106]

[0107] It can be seen that the strength and electrical conductivity of the 6201 aluminum alloy wire of this embodiment have been significantly improved, especially, compared with the comparative example, its electrical conductivity has been increased by 6.7% IACS. At the same time, the tensile strength increased by 10 MPa.

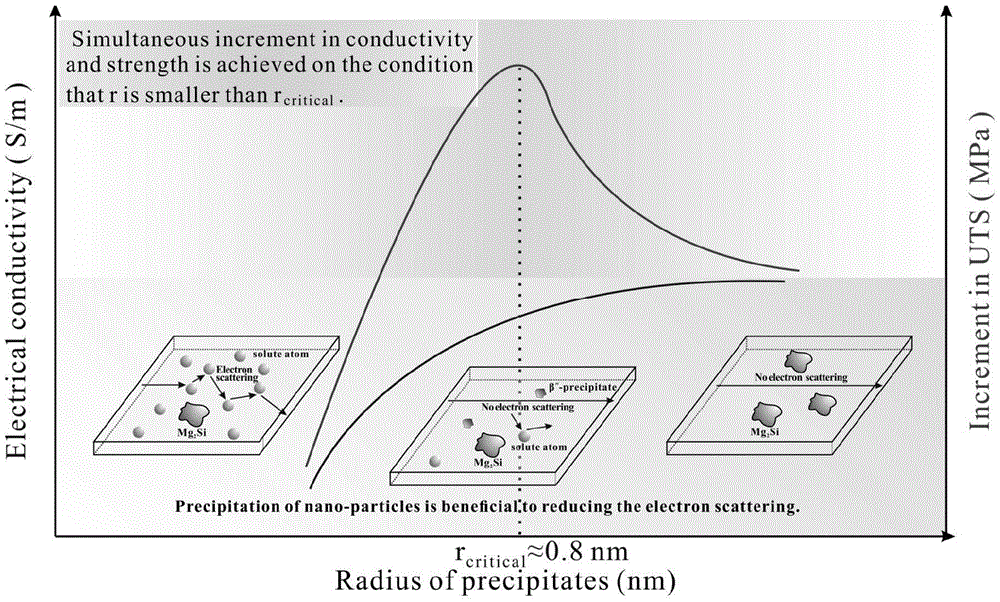

[0108] In summary, the preparation method of Example 1 can precipitate alloy atoms such as magnesium and silicon uniformly solid-dissolved in the aluminum matrix in the form of nano phases. The preparation method of Example 1 is based on the second phase precipitation strengthening theory, which changes the strengthening idea of the traditional process, adjusts the microstructure of the aluminum-magnesium-silicon alloy wire through solution treatment + aging heat treatment, and realizes that alloy atoms s...

Embodiment 2

[0114] A method for preparing an aluminum-magnesium-silicon alloy wire containing a nanophase, specifically comprising the following steps:

[0115] Step 1, alloy melting:

[0116] (1) Weigh the ingredients according to the 6101 aluminum alloy composition commonly used in the selection of overhead wires;

[0117] (2) Using an intermediate frequency induction furnace, place the aluminum ingot in the crucible, raise the temperature of the furnace to 720°C, after the aluminum ingot is melted, wrap other alloy elements with aluminum foil and put them into the aluminum liquid, add 1% of the alloy mass Ti was used as a grain refiner, and the temperature was kept for 30 minutes, and N with a purity of 99.9% was used 2 Degassing to obtain 6101 aluminum alloy liquid;

[0118] Step 2, casting:

[0119] A 6101 aluminum alloy round bar with a diameter of 100 mm and a length of 6 m was produced by using a vertical round bar continuous casting machine;

[0120] Sampling and analysis of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com