Thread guidance device for a textile machine, in particular for a ring spinning machine

A technology of guiding device and textile machine, which is applied in the direction of textiles and papermaking, and can solve the problems that the spinning machine is not feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

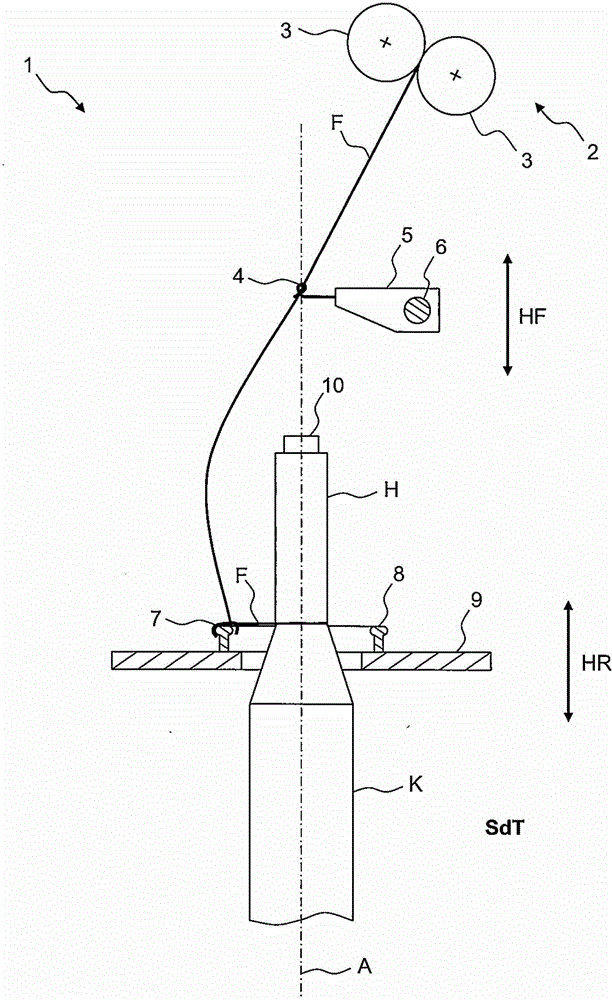

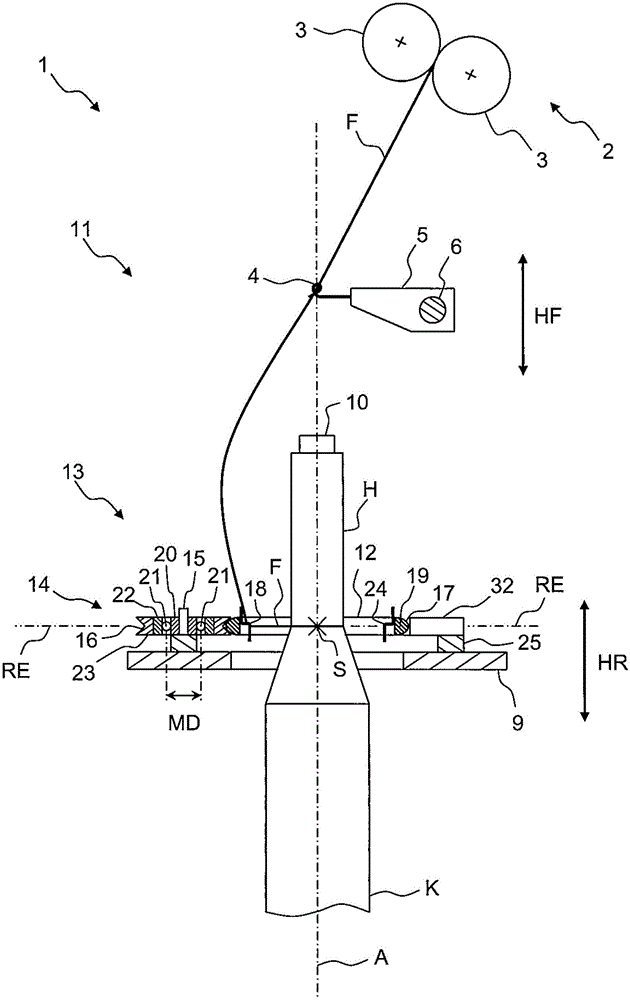

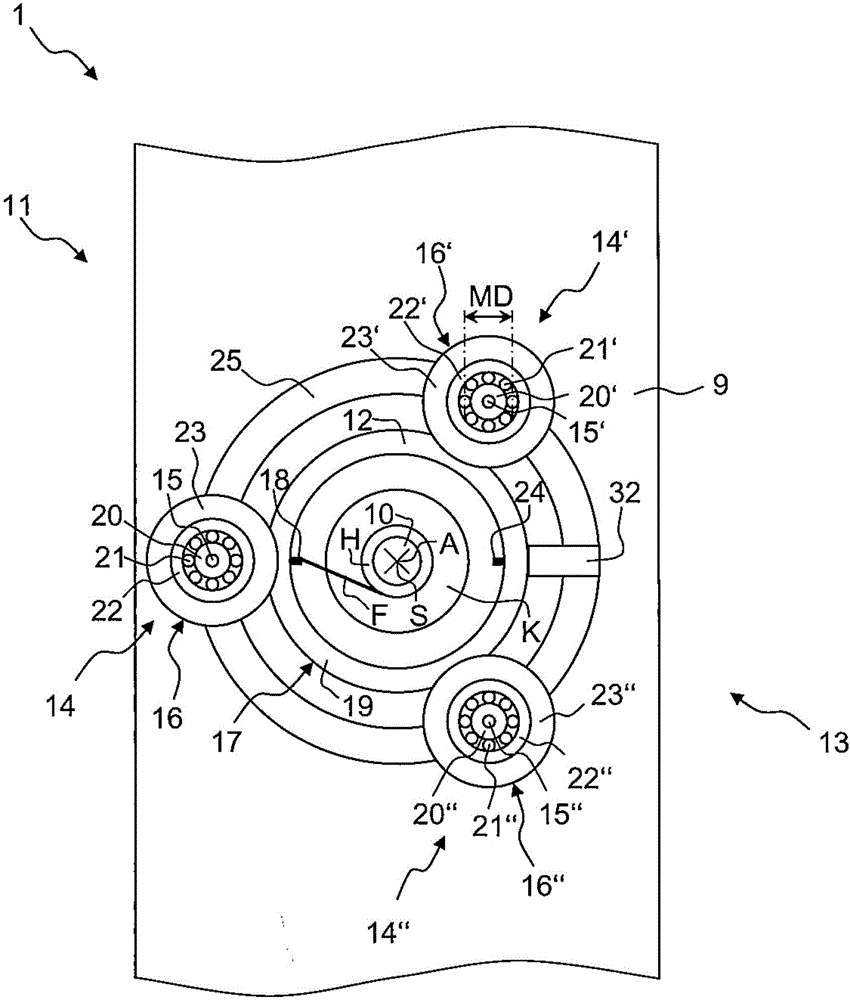

[0061] figure 1 An exemplary embodiment of a spinning table 1 of a conventional ring spinning machine is shown in a schematic side view. In practice, the ring spinning machine has a plurality of such spinning stands which are arranged one behind the other in the plane of the illustration.

[0062] The spinning stand 1 has a stretching device 2 of which only one delivery roller pair 3 is shown. The drawing device serves to modify the conveyed roving and to provide it as yarn F in the desired fineness. The yarn F exits straight from the drawing device 2 through the yarn guide hole 4 which is fixed via the holder 5 to the yarn guide platform 6 above the spinning stands 1 extend. The yarn F runs in an arc along the yarn guide hole 4 downstream to the moving part 7, which is hung on the ring 8, which is fixed on one side thereof to an annular platform 9, which is placed on the The plurality of spinning stands 1 extend above. The movement 7 reverses the yarn F so that it runs t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com