Ceramic heating slice

A ceramic heating element and ceramic technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of alumina ceramic heating elements that do not meet the requirements, reduce the risk of disconnection of heating lines, and reduce material costs , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

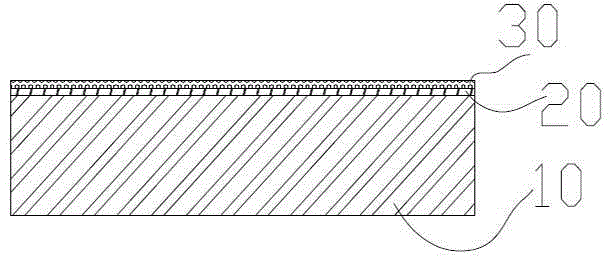

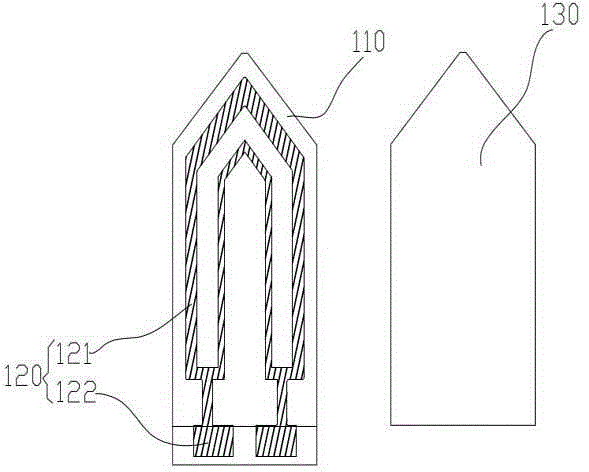

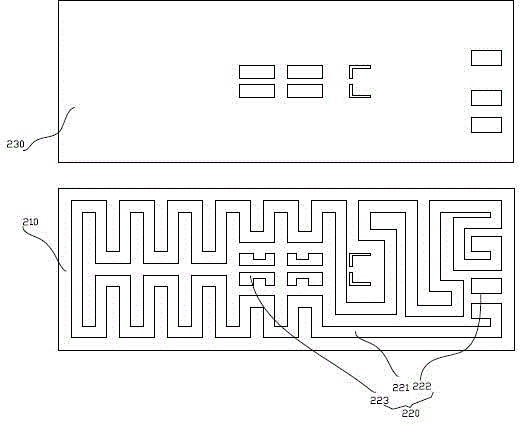

[0027] figure 1 A schematic cross-sectional structure diagram of the ceramic heating sheet of the present invention is given, figure 2 It is a schematic structural diagram of the ceramic heating sheet for rapid food detection of the present invention, image 3 It is a schematic structural diagram of the medical ceramic heating sheet of the present invention, combined with Figure 1~3 It can be seen that the ceramic heating sheet of the present invention includes a ceramic substrate (10, 110, 210) in the lower layer, which is an alumina ceramic material, preferably an alumina ceramic with an Al2O3 content of 92 or more, and is prepared by tape casting; the printed circuit of the middle layer (20, 120, 220 ), the printed circuit adopts a paste containing metal tungsten, and is mixed with Al2O3 according to the resistance requirement. Usually, the printed cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com